A Construction Method of Dynamic 3D Process Model

A technology of process model and construction method, which is applied in 3D modeling, image data processing, special data processing applications, etc., can solve problems such as difficult management and unintuitive expression of two-dimensional engineering drawing information, so as to improve production efficiency and shorten preparation time. Periodic and interactive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

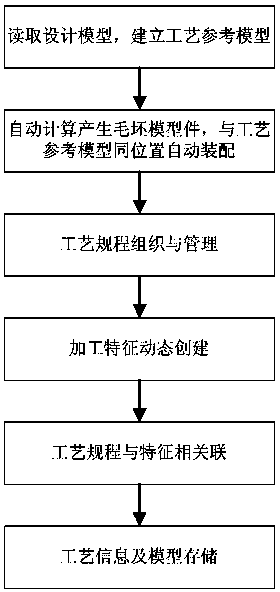

[0027] Such as figure 1 As shown, a method for constructing a dynamic three-dimensional process model needs to be implemented according to the following six steps:

[0028] Step 1. Read the design model and establish a process reference model; based on the Pro / E secondary development technology, realize the automatic generation of the design model to the process reference model;

[0029] Step 2, automatically calculate and generate the rough model, and automatically assemble at the same position as the process reference model; automatically calculate and generate the blank based on the process reference model to automatically calculate the maximum external dimension, provide standard blank raw materials, which are square or cylindrical, and produce The blank model, the whole process is automated through the secondary development technology of Pro / E; the automatic assembly of the blank model and the process reference model at the same position refers to the creation of a proces...

Embodiment 2

[0047] The steps of this embodiment are basically the same as those of Embodiment 1.

[0048] like image 3 As shown, the user runs this software in the Pro / E environment, enters the process reference model creation interface (the design model has been imported), and clicks the "Copy" button to copy a process reference model with the suffix "REF" from the design model ;Click the "Get" button to get the drive size information from the process reference model; click the "Median" button to automatically take the median value according to the upper and lower tolerances for the size selected in the interface; click the "Modify" button to save the size list Write the new size value in the model back to the model, and regenerate the reference model after the write is successful.

[0049] Figure 4 Create an interface for the process model. The user selects the blank type in the dialog box, and enters the corresponding allowance value. Taking a square workpiece as an example, the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com