Method for detecting residual quantity of perfluoroalkylation compounds in cosmetics

A perfluoroalkyl and detection method technology, applied in measuring devices, instruments, scientific instruments, etc., can solve problems such as no perfluoroalkyl compound method, and achieve advanced detection methods, good precision and reproducibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

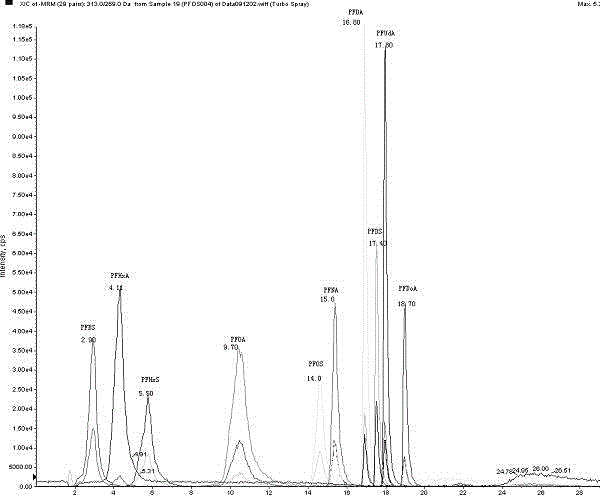

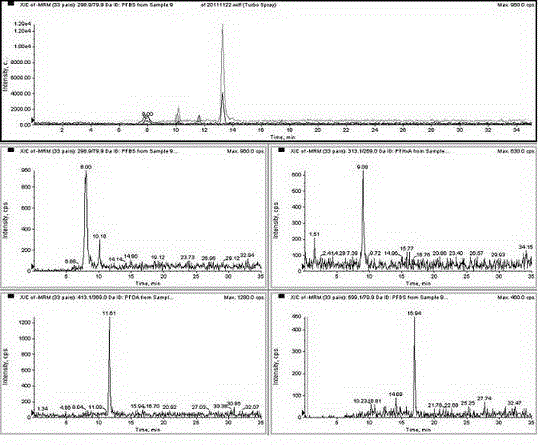

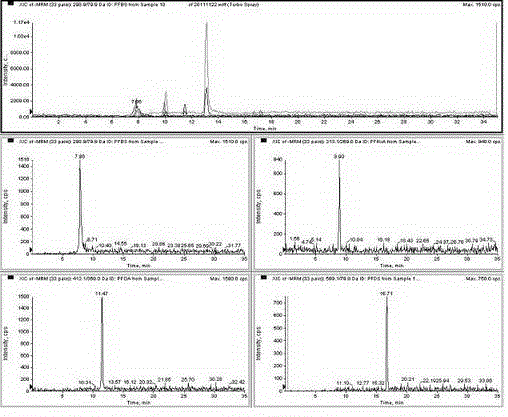

Image

Examples

Embodiment 1

[0051] liquid sample

[0052] 1. Weigh 1g sample (Lotion No. 1 provided by Liaoning Entry-Exit Inspection and Quarantine Bureau) into a 50 mL centrifuge tube, add 20 mL methanol, shake and extract with an oscillator for 30 min, then ultrasonically extract for 20 min; place in a centrifuge Centrifuge at 10000 r / min for 10 min. Pipette the supernatant into a 250 mL concentrator bottle and repeat the above extraction steps, combine the extracts, and concentrate by rotary evaporation in a water bath at 40 °C. Dilute to 10 mL with methanol, take 1 mL of the solution in a polypropylene centrifuge tube, dilute to 20 mL with water, adjust the pH to 4-5 with 2% formic acid, and wait for purification.

[0053] 2. After the extraction is complete, transfer the extract to a 250 mL concentrator bottle, and concentrate by rotary evaporation in a water bath at 40 °C. Dilute to 10 mL with methanol, take 1 mL of the solution in a polypropylene centrifuge tube, dilute to 20 mL with water, a...

Embodiment 2

[0055] powdery, milky samples

[0056] Weigh 1 g of sample (Lipstick No. 2 provided by Liaoning Entry-Exit Inspection and Quarantine Bureau), add about 5 g of diatomaceous earth, and mix well; put it into the extraction pool for extraction, and the extraction conditions of the fast solvent extraction instrument: Sample pool temperature: 80 ℃ ; Pressure: 1500 psi; Heating time: 5 min; Static extraction time: 5 min; Solvent: methanol; Flushing volume: methanol (60% of the sample cell volume); Nitrogen purge: 60 s; After completion, the extract was transferred to a 250 mL concentrator bottle, and concentrated by rotary evaporation in a water bath at 40 °C. Dilute to 10 mL with methanol, take 1 mL of the solution in a polypropylene centrifuge tube, dilute to 20 mL with water, adjust the pH value to 4-5 with 2% formic acid, and wait for purification;

Embodiment 3

[0058] powdery, milky samples

[0059] Weigh 1 g of sample (emulsion No. 3 provided by Liaoning Entry-Exit Inspection and Quarantine Bureau), add about 5 g of diatomaceous earth, mix well; put it into the extraction pool for extraction, extraction conditions of fast solvent extraction instrument: sample pool temperature: 80 ℃ ; Pressure: 1500 psi; Heating time: 5 min; Static extraction time: 5 min; Solvent: methanol; Flushing volume: methanol (60% of the sample cell volume); Nitrogen purge: 60 s; After completion, the extract was transferred to a 250 mL concentrator bottle, and concentrated by rotary evaporation in a water bath at 40 °C. Dilute to 10 mL with methanol, take 1 mL of the solution in a polypropylene centrifuge tube, dilute to 20 mL with water, adjust the pH value to 4-5 with 2% formic acid, and wait for purification;

PUM

| Property | Measurement | Unit |

|---|---|---|

| Collision gas | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com