Method and system for automatically identifying coal rock interface of coal cutter, and automatically heightening roller

An automatic identification and shearer technology, which is applied in the direction of earthwork drilling and cutting machinery, etc., can solve the problems of different processing methods of drums, complexity, and limited application of memory cutting technology, and achieve comprehensive and accurate results of automatic identification of coal-rock interface. Avoid frequent adjustments and easy signal pickup

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

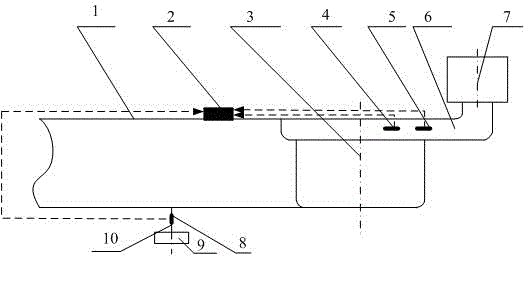

[0025] Such as figure 1 As shown, taking the cutting of the roof by the right drum of the shearer as an example, the automatic recognition of the coal-rock interface of the shearer and the automatic height adjustment system of the drum are mainly composed of the fuselage 1, the controller 2, the cutting motor 3, the height sensor 4, Cutting force response sensor 5, rocker arm 6, cylinder 7, position sensor 8, output driving wheel 9 and output shaft 10 constitute. The fuselage 1 is a rigid whole, the fuselage 1 is hinged with the rocker arm 6 , and the output end of the rocker arm 6 is connected with the drum 7 . Cutting motor 3 and rocking arm 6 are fixed together. The output shaft 10 of the traction part of the coal shearer and the output driving wheel 9 drive the coal shearer to work forward. Install the controller 2 on the body 1. The shearer position sensor 8 is installed on the output shaft 9 of the traction part of the shearer to measure the position of the shearer on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com