Coal-rock hydraulic fracturing testing method under true triaxial state

A technology of hydraulic fracturing and test method, applied in the direction of using stable tension/pressure test material strength, suspension and porous material analysis, permeability/surface area analysis, etc. Parametric equations, inability to meet test requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

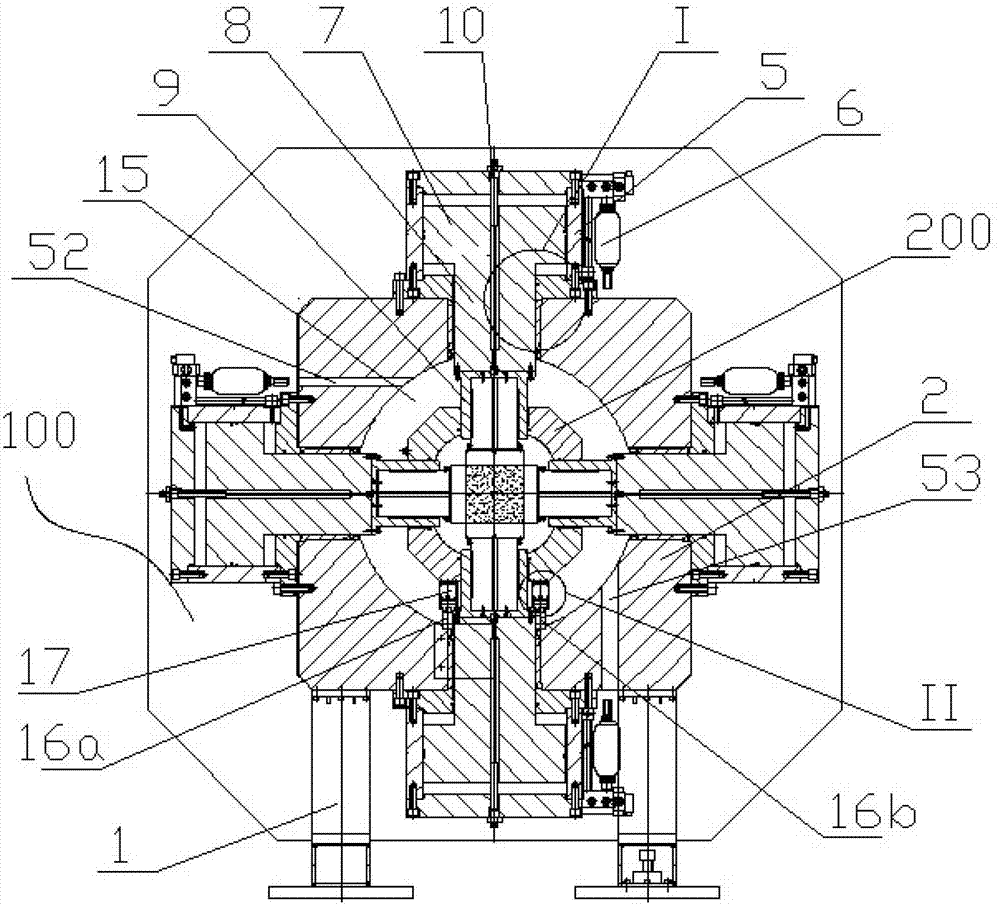

[0100] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

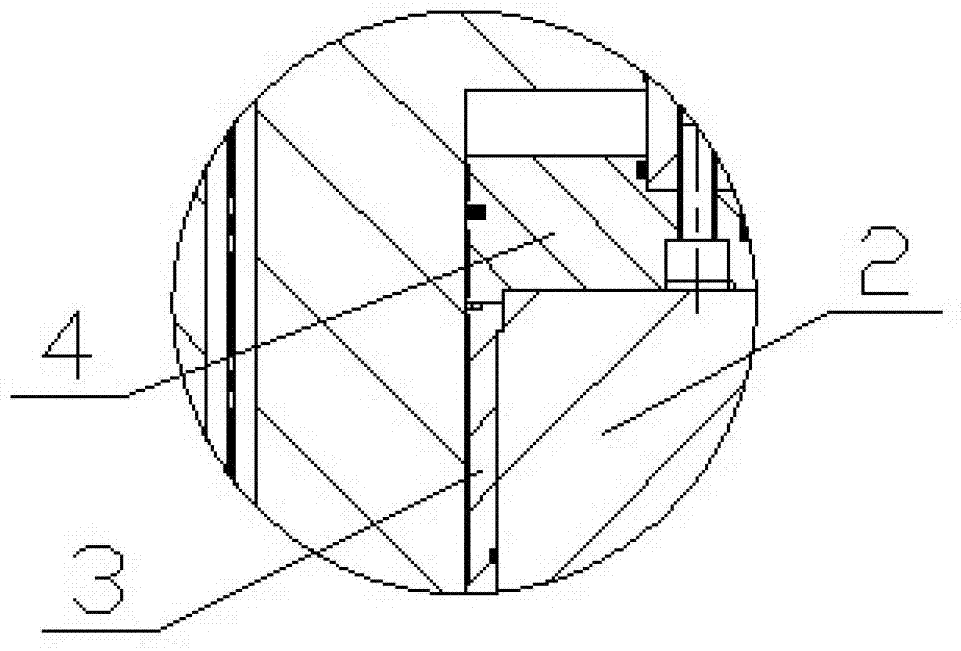

[0101] Such as Figure 1 to Figure 19 As shown, a multifunctional true triaxial fluid-solid coupling test system includes a frame 100 and a pressure chamber 200 in which coal and rock samples can be placed. The frame 100 includes a support 1 on which a frame 2 is fixedly connected.

[0102] The upper part of the frame 2 is provided with the first bushing 3, the top of the frame 2 is fixedly connected with the first end cover 4, and the outer side of the first end cover 4 is fixed with the first oil cylinder 5, the first oil cylinder 5 and the first servo oil circuit 6 connections. A first oil cylinder piston 7 and a first oil cylinder piston rod 8 are integrally arranged in the first oil cylinder 5 , and a first oil cylinder displacement sensor 10 is arranged in the first oil cylinder piston 7 and the first oil cylinder piston rod 8 .

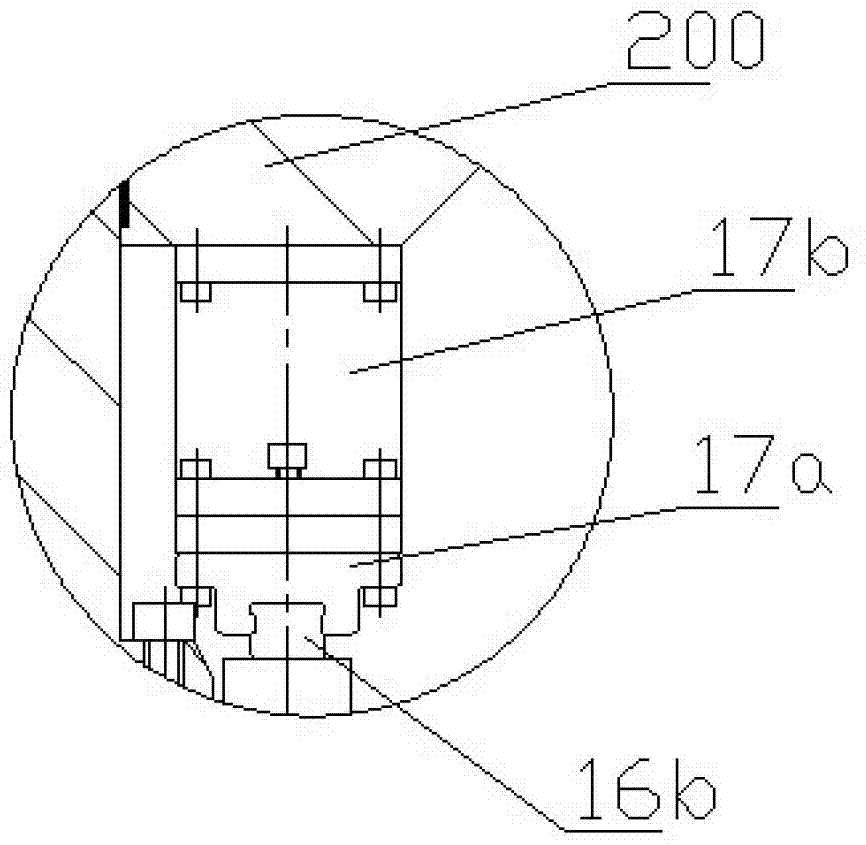

[0103] The lower par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com