Construction Technology of Welding Materials for Cracks in Pavement Asphalt Surface

A welding technology for asphalt pavement and cracks, which is applied in the direction of roads, roads, pavement details, etc., can solve the problems that cracks are easy to crack again, can not solve structural damage, consume a lot of manpower and material strength, and achieve permeability and expansion Strong performance, saving manpower and financial resources, and reducing maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

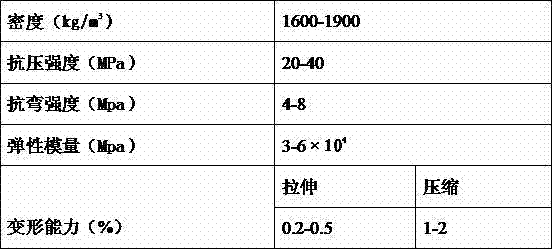

Embodiment 1

[0027] The invention discloses a crack welding material for asphalt pavement, which is made of 84kg of aggregate, 12kg of polymer material and 3kg of additives.

[0028] The aggregate is sand and gravel with a diameter of 0-0.5 mm or 0.5-3 mm.

[0029] The polymer material described is one-component polyurethane 。

[0030] The additive is one or a combination of butyl acrylate, xylylenediamine, ethylenediamine, and polyacrylic acid 。

[0031] The construction process of the crack welding material for the asphalt surface layer of the road surface, the construction process comprises the following steps:

[0032] Step 1. Detection: Use ground penetrating radar to detect the position, depth, and width of cracks in the asphalt pavement, and record them;

[0033] Step 2. Material selection: Determine the material diameter of the aggregate to be used according to the width of the crack detected in step 1. Where the crack width is greater than 5 mm, use aggregates with a material ...

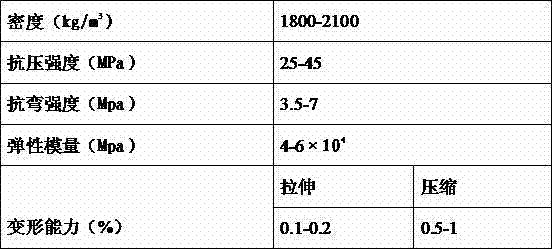

Embodiment 2

[0041] The invention discloses a crack welding material for asphalt pavement, which is made of 85kg of aggregate, 11kg of polymer material and 4kg of additives.

[0042] The aggregate is sand and gravel with a diameter of 0-0.5 mm or 0.5-3 mm.

[0043] The polymer material described is two-component polyurethane 。

[0044] The additive is one or a combination of butyl acrylate, xylylenediamine, ethylenediamine, and polyacrylic acid 。

[0045] The construction process of the crack welding material for the asphalt surface layer of the road surface, the construction process comprises the following steps:

[0046] Step 1. Detection: Use ground penetrating radar to detect the position, depth, and width of cracks in the asphalt pavement, and record them;

[0047] Step 2. Material selection: Determine the material diameter of the aggregate to be used according to the width of the crack detected in step 1. Where the crack width is greater than 5 mm, use aggregates with a material ...

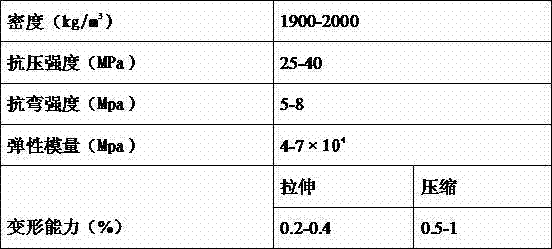

Embodiment 3

[0055]A welding material for cracks in asphalt pavement, which is made of 83kg of aggregate, 14kg of polymer material and 3kg of additives.

[0056] The aggregate is sand and gravel with a diameter of 0-0.5 mm or 0.5-3 mm.

[0057] The polymer material is a liquid resin 。

[0058] The additive is one or a combination of butyl acrylate, xylylenediamine, ethylenediamine, and polyacrylic acid 。

[0059] The construction process of the crack welding material for the asphalt surface layer of the road surface, the construction process comprises the following steps:

[0060] Step 1. Detection: Use ground penetrating radar to detect the position, depth, and width of cracks in the asphalt pavement, and record them;

[0061] Step 2. Material selection: Determine the material diameter of the aggregate to be used according to the width of the crack detected in step 1. Where the crack width is greater than 5 mm, use aggregates with a material diameter of 0.5-3 mm for crack welding of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com