Treatment method for improving oxidation resistance of thermal barrier coating (TBC) bonding layer

A technology of thermal barrier coating and treatment method, which is applied in the direction of coating, metal material coating technology, fusion spraying, etc., and can solve the problem of uneven growth of thermally grown oxide layer, reduction of oxidation resistance of coating, and bonding layer surface Large roughness and other problems, to achieve the effect of uniform thermal growth oxide layer, high energy utilization rate, and improve high temperature service performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

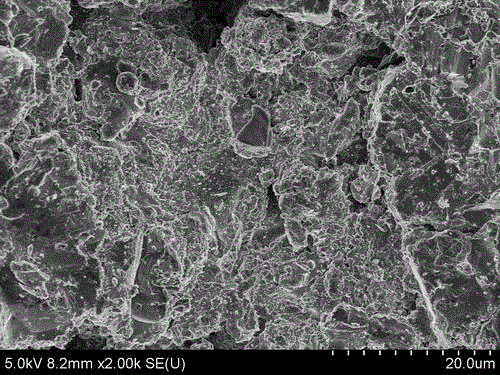

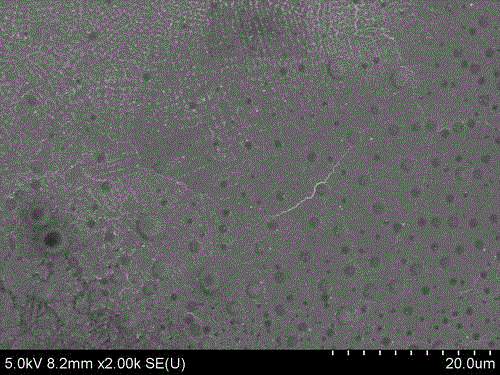

[0026] Combined with the specific experimental process, the implementation plan for improving the high-temperature oxidation resistance of the thermal barrier coating bonding layer by high-current pulsed electron beam irradiation is described in detail. Taking the same pulse width and different energy densities as an example, the specific steps are as follows:

[0027] The first step, preparation of thermal barrier coating tie layer (MCrAlY)

[0028] After the superalloy substrate (or parts such as engine blades) is pre-grinded, polished, and cleaned, the low-pressure plasma spraying method (LPPS) is used to deposit a bonding layer on the superalloy substrate. The coating material of the bonding layer is MCrAlY;

[0029] In the second step, the sample that has been sprayed with the thermal barrier coating bonding layer is fixed on the sample stage, and vacuumized

[0030] Fix the thermal barrier coating adhesive layer sample prepared by the plasma spraying method on the sample...

Embodiment 2

[0040] Combined with the specific experimental process, the implementation plan for improving the high-temperature oxidation resistance of the thermal barrier coating bonding layer by intense pulsed electron beam irradiation is described in detail. Taking the same energy density and different pulse widths as an example, the specific steps are as follows:

[0041] The first step, preparation of thermal barrier coating tie layer (MCrAlY)

[0042] After the superalloy substrate (or parts such as engine blades) is pre-grinded, polished, and cleaned, the low-pressure plasma spraying method (LPPS) is used to deposit a bonding layer on the superalloy substrate. The coating material of the bonding layer is MCrAlY;

[0043] The second step is to fix the sample with the thermal barrier coating bond layer deposited on the sample stage and vacuumize

[0044] Fix the thermal barrier coating adhesive layer sample prepared by the plasma spraying method on the sample stage of the high-current...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com