Preparation method of non-isocyanate polyurethane and application of non-isocyanate polyurethane in spraying polyurea

A non-isocyanate and polyurethane technology, applied in the field of organic polymer materials, can solve the problems of high-pollution polyisocyanate pollution, high cost of amino-terminated polyether, and inconvenient application and development, and achieve low cost, excellent hydrolysis resistance, and reduced use The effect of isocyanate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

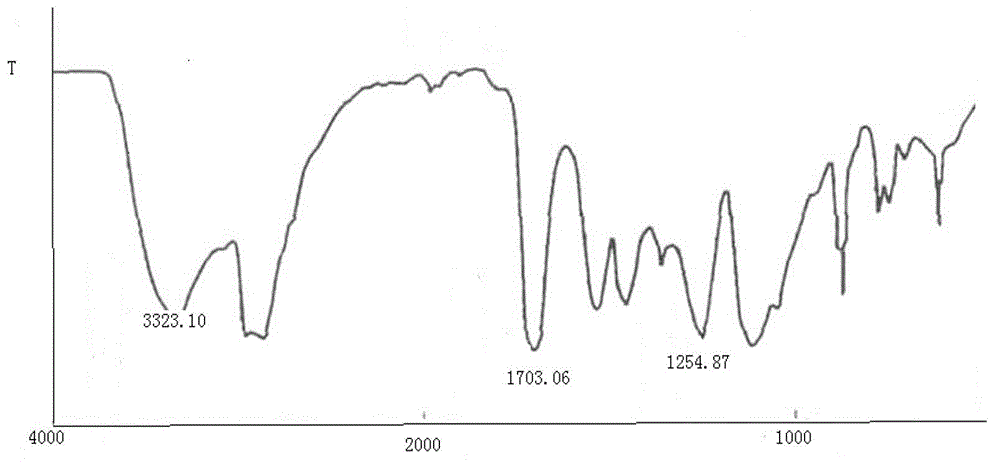

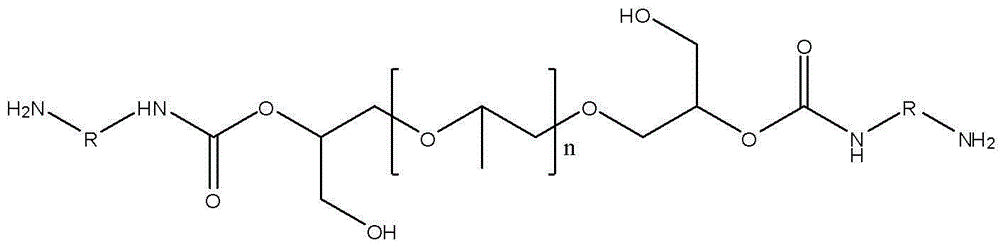

[0039] Preparation of non-isocyanate polyurethane

[0040] (1) Add 500 grams of polypropylene glycol with a molecular weight of 400 into a four-necked flask, add 25 grams of potassium hydroxide catalyst, control the temperature at 50°C and slowly add 231 grams of epichlorohydrin dropwise, and control the temperature at 80°C to react After 4 hours, add 125 g of 40% NaOH solution dropwise, finish dropping within 2 hours, keep warm at 80°C for 5 hours, wash with water repeatedly, distill and dehydrate under reduced pressure to obtain polypropylene glycol diglycidyl ether as a light yellow transparent liquid.

[0041] (2) Weigh 15 grams of potassium carbonate, 10 grams of potassium iodide and 85 grams of activated carbon, and prepare by equal-volume impregnation. The impregnation process is treated in an ultrasonic vibrator for 3 hours, then suction filtered, dried, and placed in an oven at 120 ° C. After drying for 6 hours, place it in a nitrogen atmosphere furnace, and then acti...

Embodiment 2

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com