Synthesized mica crystal plate with high flexibility and high splitting performance as well as preparation method

A technology for synthesizing mica and high peelability, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve the problems of low color saturation, poor peelability, hard synthetic mica, etc., achieve good transparency and reduce impurities Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1. A two-phase AC power supply is used.

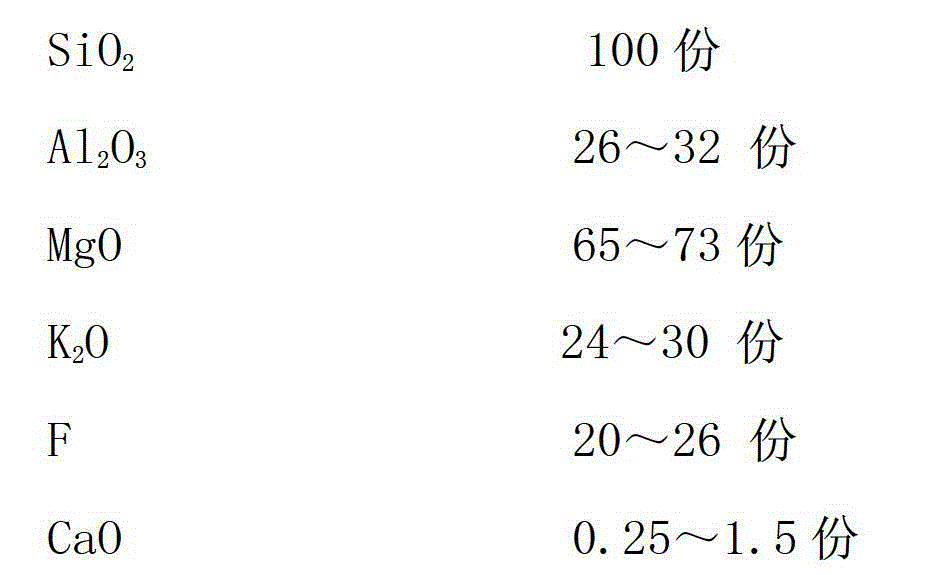

[0047] 1. The amount of raw materials is according to the following formula, calculated on the basis of one ton per mixing:

[0048]

[0049] Quartz sand, fused magnesia, alumina (industrial grade), potassium fluorosilicate, potassium carbonate and quicklime are used as raw materials. The chemical composition is shown in Table 1.

[0050] Table 1

[0051]

[0052] The actual consumption of raw materials is as follows:

[0053]

[0054] 2. Accurately weigh the actual amount of raw materials determined in the above table, and put in 2m 3 In the double-helix conical mixer, stir and mix for 15 minutes, discharge the material and bag it for standby (80kg / bag), and stir 16 times in total, totaling 15319.8kg;

[0055] 3. The volume range of the furnace body is:

[0056] V=K*W / p

[0057] =(1.05~1.2)×15.3198÷2.8

[0058] =5.74~6.56(m 3 )

[0059] According to the volume range of the furnace body, the clearance...

Embodiment 2

[0075] Embodiment 2 uses a two-phase AC power supply.

[0076] The amount of raw materials is according to the following formula, based on 1 ton of mixing and stirring each time:

[0077]

[0078] Still using quartz sand, fused magnesia, alumina (industrial grade), potassium fluorosilicate, potassium carbonate, and quicklime as raw materials, the chemical composition is the same as that in Table 1 of Example 1. The actual amount of each raw material is:

[0079]

[0080] 2. Accurately weigh the actual amount of raw materials determined in the above table, and put in 2m 3In the double-helix conical mixer, stir and mix for 38 minutes, discharge and bag for standby (80kg / bag), need to stir 16 times in total, totaling 16012.8kg;

[0081] 3. The volume range of the furnace body is:

[0082] V=K*W / p

[0083] =(1.05~1.2)×16.0128÷2.8

[0084] =6.0~6.86(m 3 )

[0085] According to the volume range of the furnace body, the clearance size of the furnace body is determined as...

Embodiment 3

[0101] Embodiment 3 uses a two-phase AC power supply.

[0102] The amount of raw materials is according to the following formula, with each batch being stirred as 1 ton:

[0103]

[0104] Still using quartz sand, fused magnesia, alumina (industrial grade), potassium fluorosilicate, potassium carbonate, and quicklime as raw materials, the chemical composition is the same as that in Table 1 of Example 1. The actual amount of each raw material is:

[0105]

[0106] Since the amount of calcium oxide contained in the raw material is greater than the calcium oxide required by the formula, there is no need to add calcium oxide.

[0107] 2. Accurately weigh the actual amount of raw materials determined in the above table, and put in 2m 3 In the double-helix conical mixer, stir and mix for 60 minutes, discharge and pack into bags for standby (80kg / bag), and stir 16 times in total, totaling 15469.6kg;

[0108] 3. The volume range of the furnace body is:

[0109] V=K*W / p

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com