Continuous acid-washing-free drawing process

A technology without pickling and wire drawing, applied in manufacturing tools, metal processing equipment, cleaning equipment for metal extrusion, etc. Cost, high production efficiency, and the effect of saving water and electricity resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

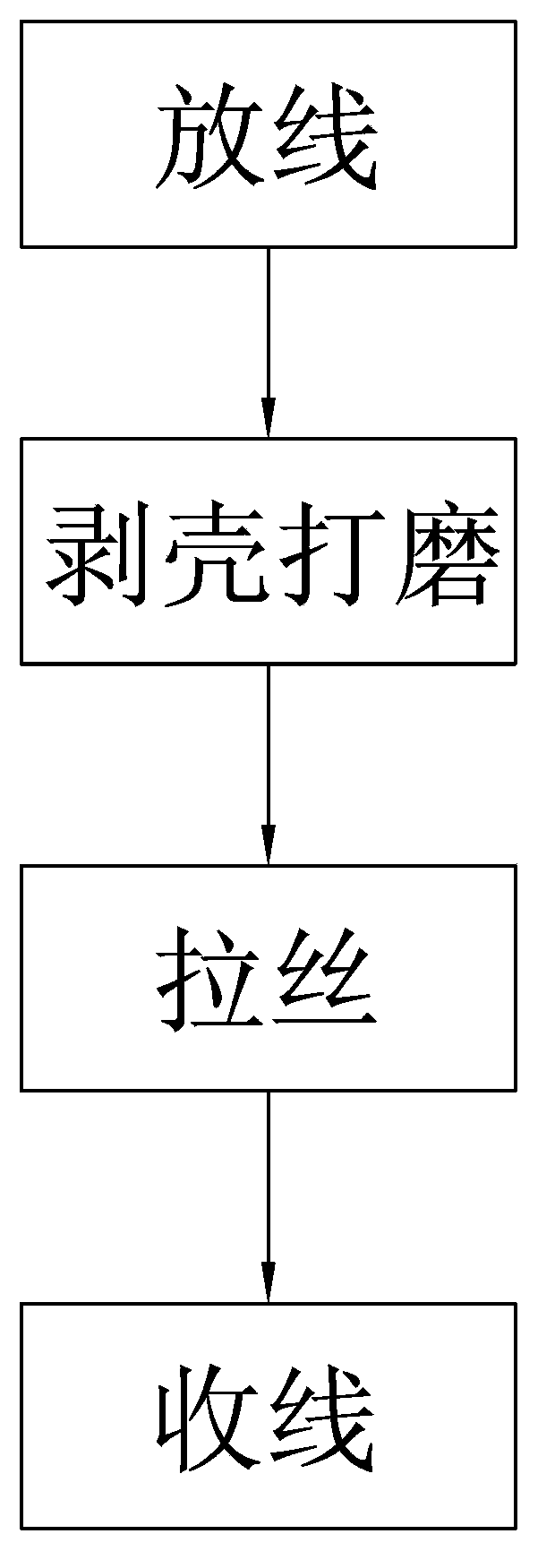

[0022] Such as figure 1 As shown, a continuous non-pickling wire drawing process, its technological process is as follows:

[0023] (1) Pay-off: place the wire to be processed on the pay-off, then pull the wire out and enter the shelling device;

[0024] (2) Peeling and grinding: Wind the wire on the four shelling wheels, change the bending rate of the wire to achieve the purpose of peeling, and pull the wire to the grinding mechanism after the shelling is completed. Grinding to remove rust on the wire surface;

[0025] (3) Wire drawing: After the grinding is completed, the wire is drawn to the dry drawing machine and the water tank machine in turn for drawing;

[0026] (4) Take-up: After the wire drawing is completed, the wire is taken up by an automatic take-up machine.

[0027] The entire technological process will be described in detail below in conjunction with specific technological parameters.

[0028] Place the wire to be processed with a diameter of 6.5mm on the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com