Improved curing auxiliaries

A technology for additives and pickling salt, which is applied in the field of meat products and fish products containing muscle, and can solve the problems of unfavorable persistence, time-consuming and short time of reddening process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1- Embodiment 6

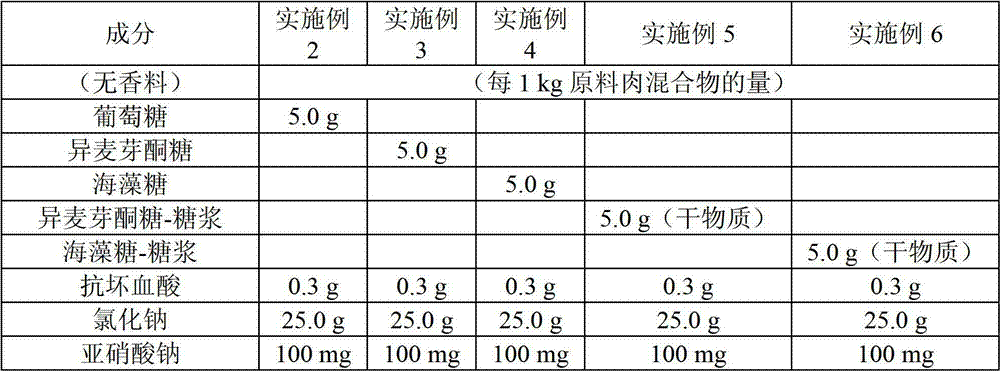

[0083] A raw meat mixture containing 20% beef, 50% lean pork and 30% pork fat was processed in a known manner into a raw sausage with the curing components given in Table 1A. (Example 1 is a pure raw meat mixture without adding nitrite curing salt and curing additives. In Example 1, the residual nitrite content and the red value of reddening cannot be determined. The results of this example are given in the following Not shown in the table.) Example 2 is a comparative test using a known curing composition.

[0084] Table 1B and Table 1C each show the residual nitrite content and the degree of redness, respectively, determined after a 24-hour or 74-hour aging time.

[0085]Table 1A

[0086]

[0087] Table 1B

[0088]

[0089] Table 1C

[0090]

Embodiment 7- Embodiment 13

[0092] A raw meat blend made from 40% beef, 40% lean pork and 20% fat. Raw sausages were thus produced by using the various curing materials given in Table 2A.

[0093] Table 2B shows the residual nitrite content and degree of redness after 24 hours and 120 hours of aging time, respectively.

[0094] Table 2A

[0095]

[0096]

[0097] Table 2B

[0098]

Embodiment 14- Embodiment 21

[0100] A raw meat mixture made from 45% beef, 35% lean pork, and 20% fat, processed into raw sausages using the curing ingredients given in Table 3A, respectively.

[0101] Table 3B shows the degree of redness and residual nitrite content after aging for 17 hours and 72 hours, respectively.

[0102] Table 3A

[0103]

[0104]

[0105] Table 3B

[0106]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com