Heat dissipation processing device and mobile terminal

A mobile terminal and processing device technology, applied in the field of mobile communication, can solve the problems of high price and difficult comprehensive effect, and achieve the effect of improving grounding performance and radio frequency signal receiving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

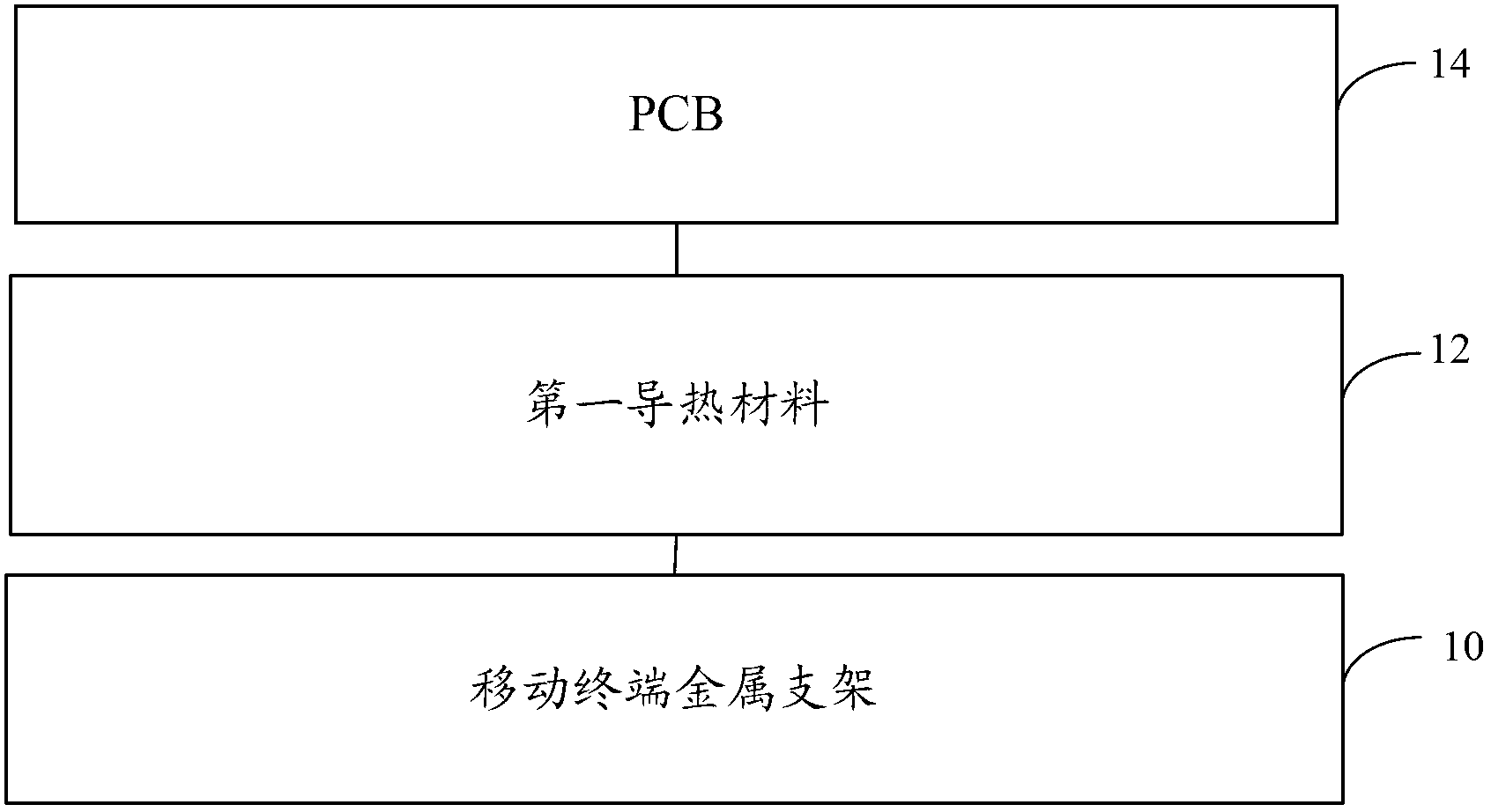

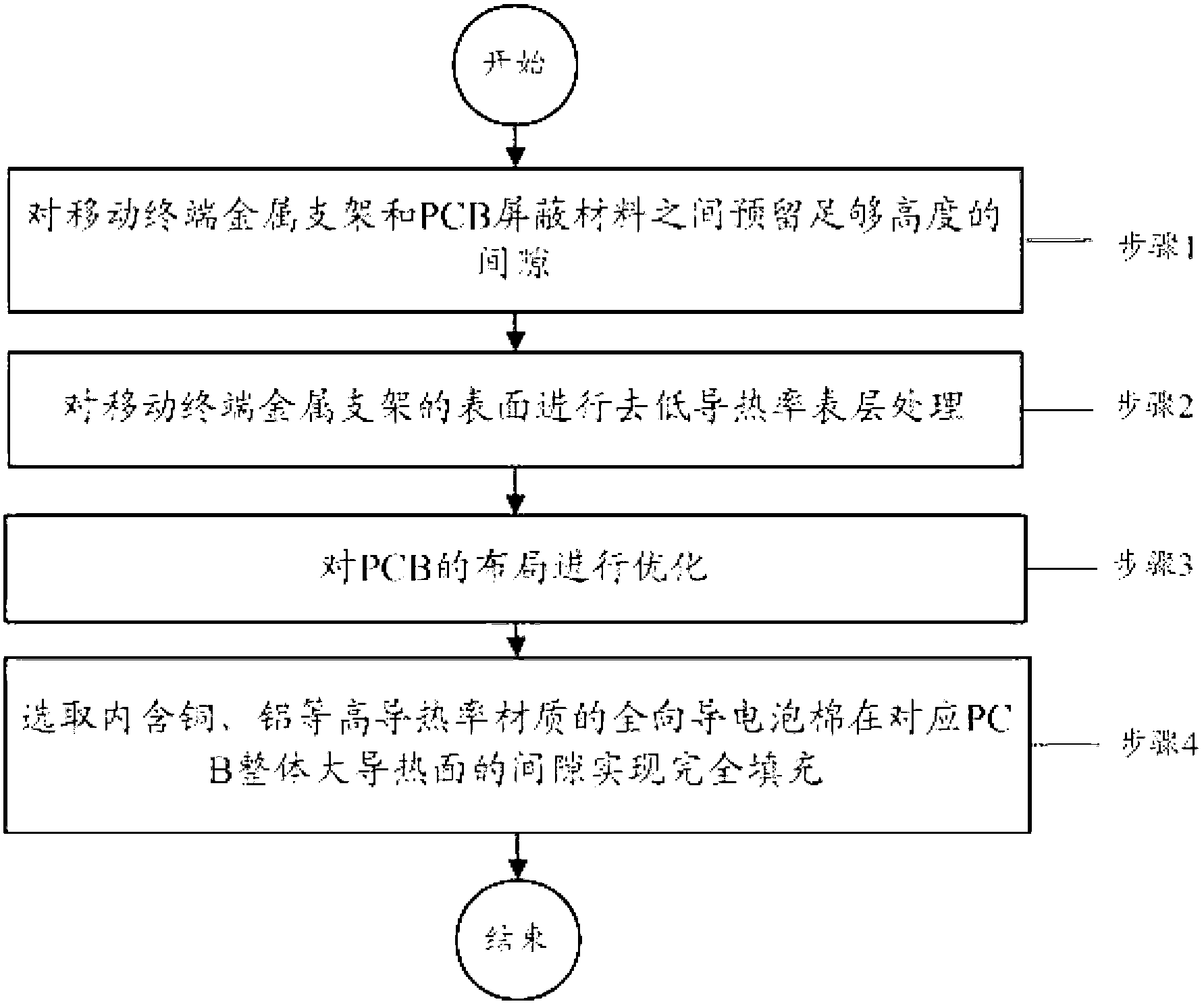

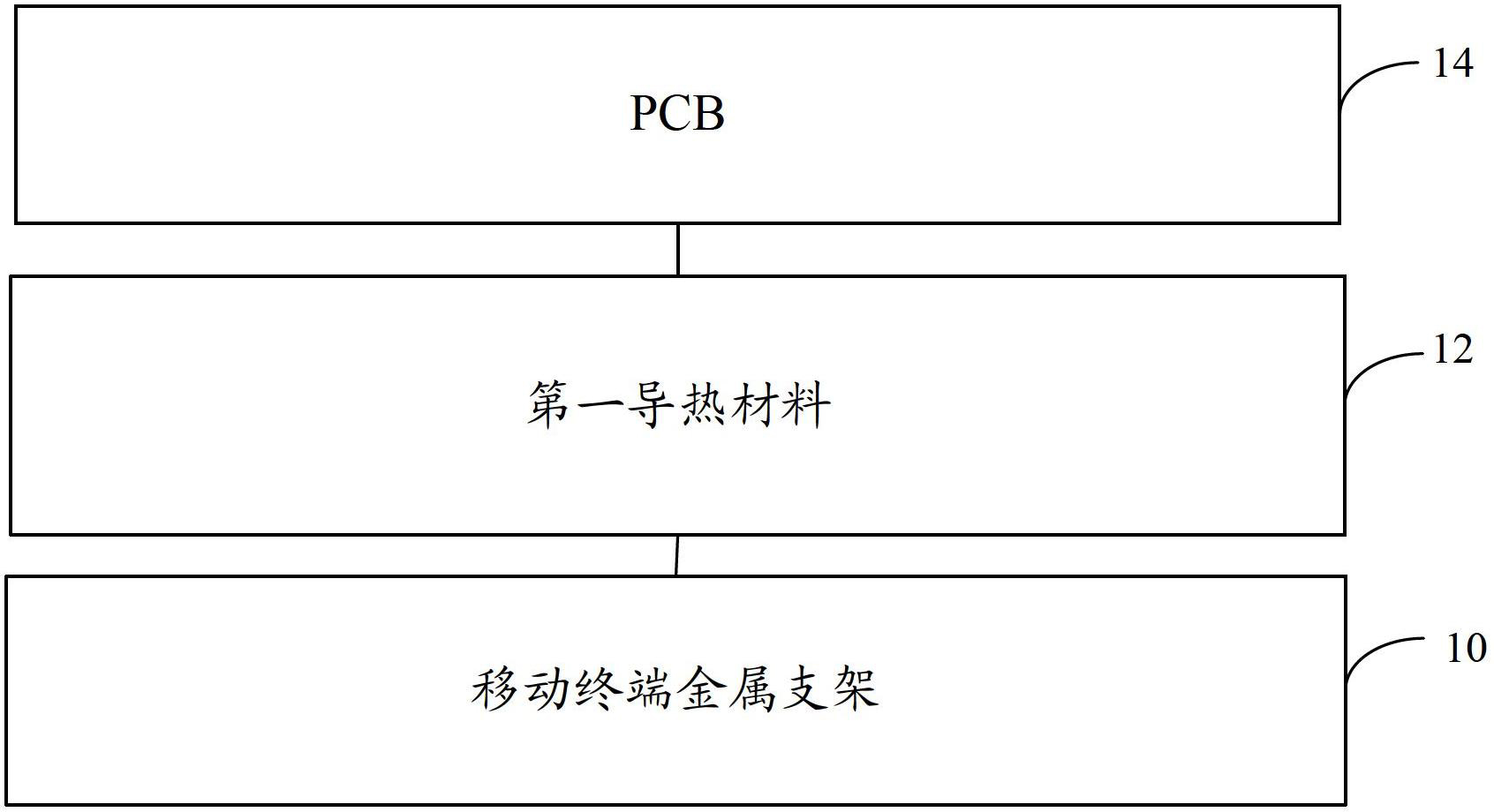

[0023] According to an embodiment of the present invention, a heat dissipation processing device is provided, figure 1 is a schematic diagram of a heat dissipation processing device according to an embodiment of the present invention, such as figure 1 As shown, the heat dissipation treatment device according to the embodiment of the present invention includes: the metal bracket 10 of the mobile terminal that has been treated to remove the low thermal conductivity surface layer, the first thermally conductive material 12 with a rough surface, and the PCB 14 with a multi-layer structure. The following describes the embodiment of the present invention Each module is described in detail.

[0024] Specifically, the mobile terminal metal bracket 10 is located between the mobile terminal LCD and the PCB 14, and a certain gap needs to be maintained between the mobile terminal metal bracket 10 and the PCB 14. In the embodiment of the present invention, the mobile terminal metal bracket...

Embodiment 2

[0054] According to an embodiment of the present invention, a mobile terminal is provided. The mobile terminal according to the embodiment of the present invention includes the heat dissipation processing device described in the first embodiment of the device. The embodiment of the present invention can be understood according to the description of the first embodiment of the device above. I won't repeat them here.

[0055] To sum up, with the help of the technical solution of the embodiment of the present invention, by filling the gap between the metal bracket of the mobile terminal and the PCB with the low thermal conductivity surface treatment in the past, a conductive heat-conducting material can be used to effectively dissipate heat in the electronic system of the mobile terminal. While processing, it can improve the grounding performance of the electronic system and the receiving performance of radio frequency signals.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com