Method for manufacturing circuit board by addition method

An additive and circuit technology, applied in the direction of conductive pattern formation, etc., can solve the problems of difficult etching, etching of base copper foil, side etching of lines, etc., to achieve the effect of cost and environmental advantages

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

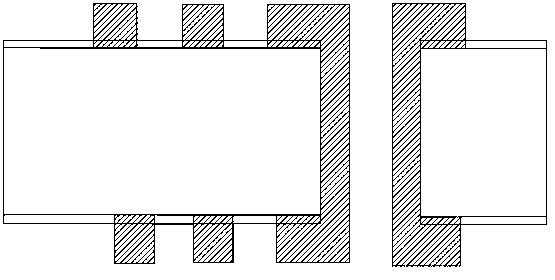

Image

Examples

Embodiment Construction

[0017] In order to illustrate the specific implementation method of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

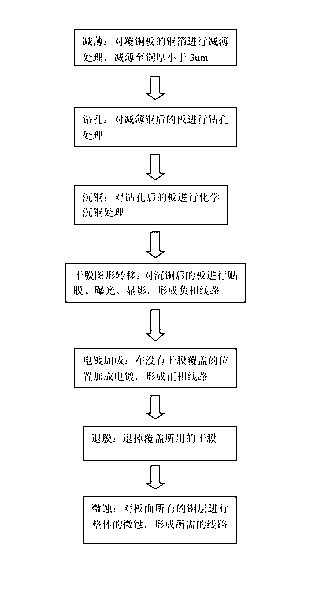

[0018] The process of the invention is: thinning→drilling→copper sinking→dry film pattern transfer→electroplating addition→film removal→microetching.

[0019] Thinning: The copper foil of the copper clad laminate is thinned until the copper thickness is less than 3um. The thinner the initial thickness of the copper foil, the better. Generally, a copper thickness of 18um is used. The adjustment is based on the etching speed of the 18um copper foil in the inner layer, which is twice the etching rate of the inner layer, and the remaining thickness of the copper foil is less than 3um and the base material is slightly exposed.

[0020] Drilling: Drilling is performed on the thinned copper board. Before the thinning is drilled, it is to avoid etching the inner layer of the multilay...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com