AlGaInP light-emitting diode (LED) chip and cutting method for same

A technology of LED chips and cutting methods, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high machine cost and labor cost, fast cutting knife wear, low product qualification rate, etc., to reduce labor and machine costs. cost, improve the brightness of the light, and increase the effect of the light-emitting area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

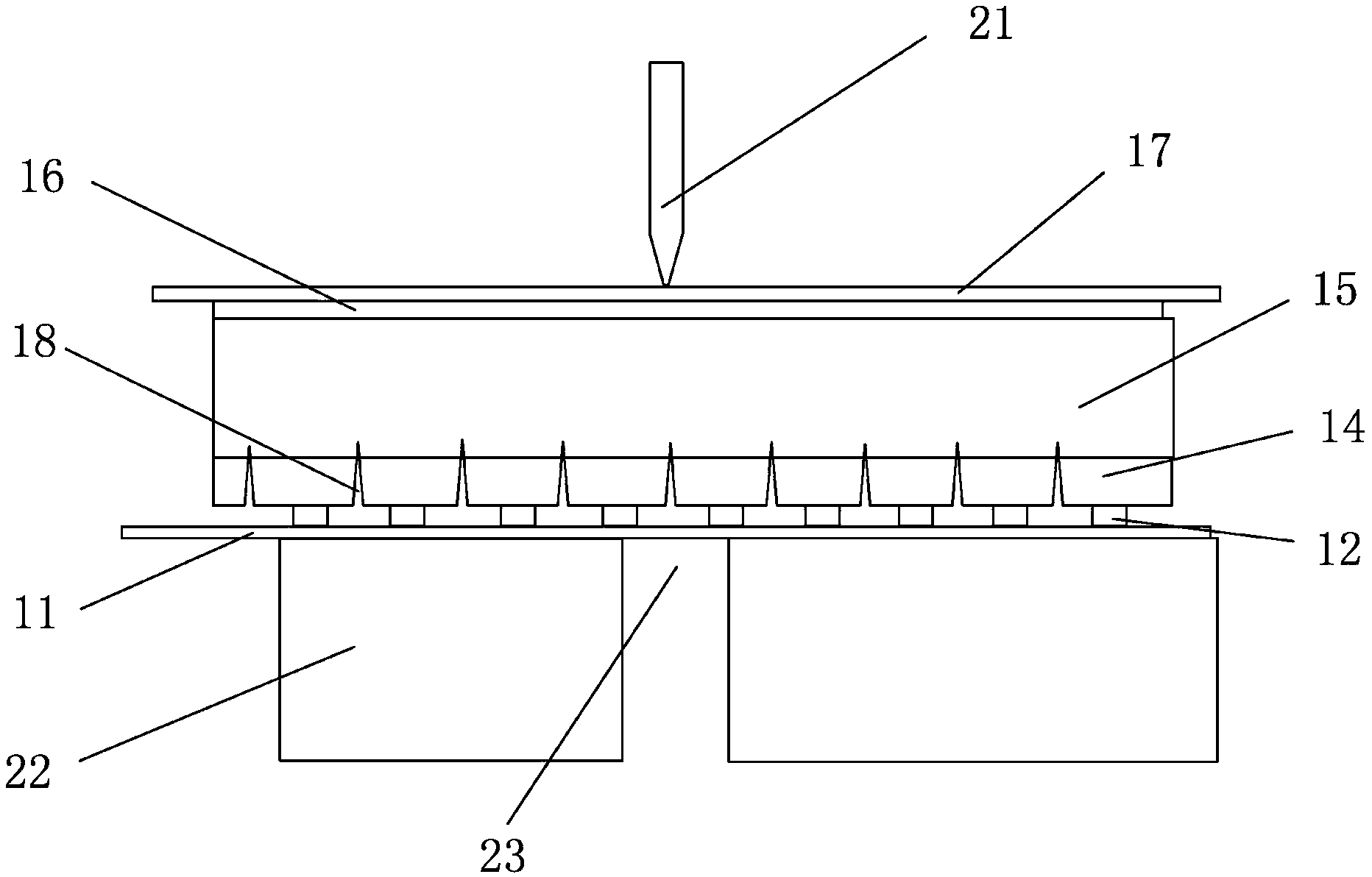

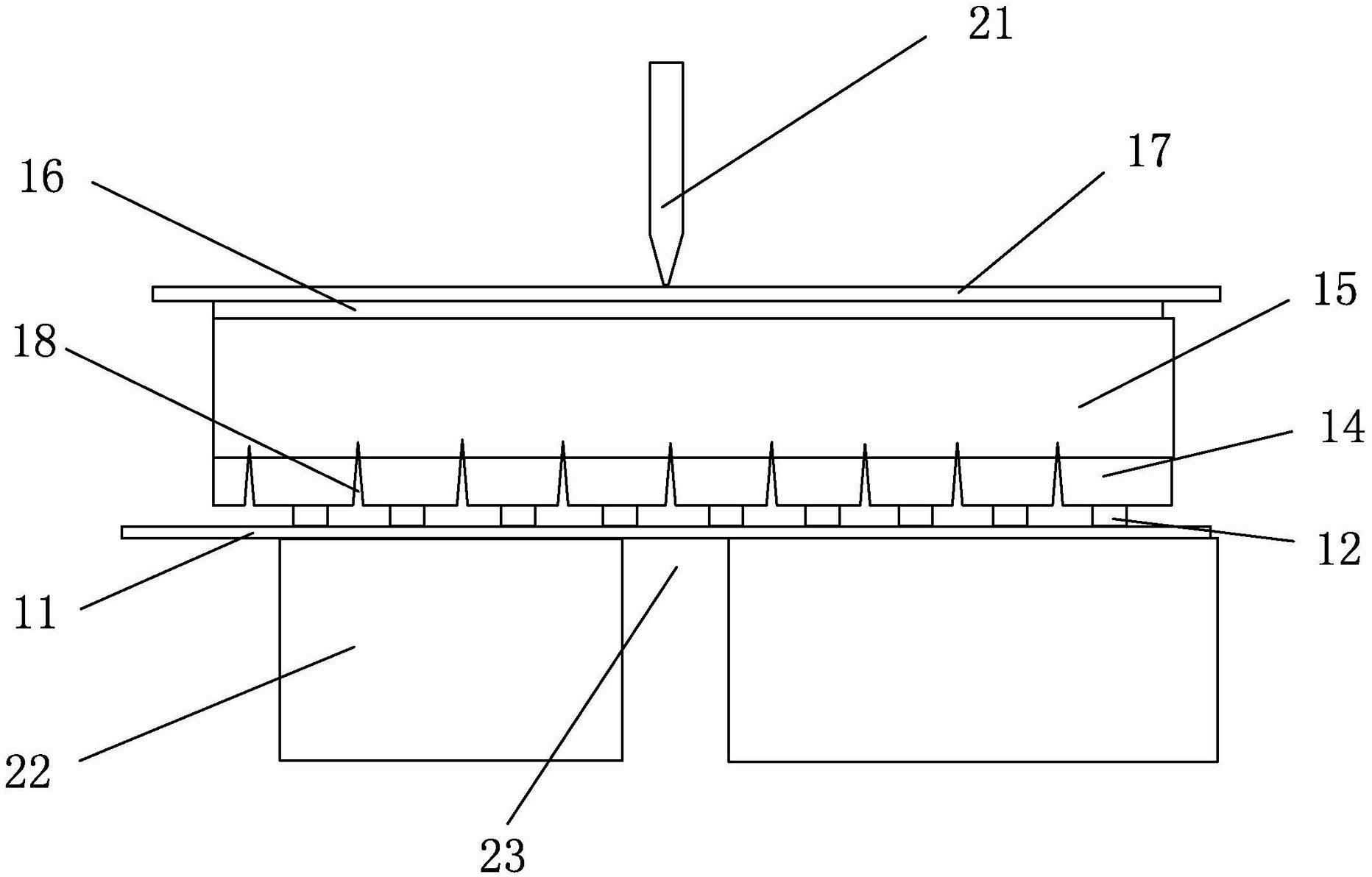

[0029] A kind of quaternary system LED chip of the present invention, as figure 1 as shown,

[0030] A GaAs substrate 15 is included as an epitaxial layer substrate. As a substrate material for quaternary red-yellow LED chips, GaAs has obvious advantages. GaAs has very stable chemical properties, good lattice matching with quaternary materials, and good electrical and thermal conductivity.

[0031] One side of the GaAs substrate 15 is epitaxially formed with an epitaxial layer 14 , that is, the PN junction of the LED chip.

[0032] The other side of the GaAs substrate 15 is plated with an Au thin film layer, which serves as the negative terminal 16 of the LED chip. Before the Au thin film layer is plated, the wafer needs to be cleaned by a chemical solution.

[0033] On the epitaxial layer 14 are deposited BeAu thin film layers arranged at equal intervals, and on the BeAu thin film layer is also deposited an Au thin film layer as the positive terminal 12 of the LED chip. ...

Embodiment 2

[0037] A cutting method of a quaternary LED chip of the present invention, such as figure 1 As shown, the positive end 12 of the LED chip is half-cut with a diamond cutter to form a cutting line 18, and the positive end 12 of the LED chips arranged at equal intervals is separated, and then the negative end 16 of the LED chip is cut along the edge with a splitter. Road 18 cuts off the half-cut LED chip. Generally speaking, the basic thickness of the LED chip is 100 μm-300 μm, and the depth of the corresponding cutting line 18 should be 25 μm-250 μm. The half-cut depth can ensure that the epitaxial layer 14 is completely cut off. , the GaAs substrate 15 is cut with traces to ensure that the GaAs substrate 15 is easily split along the cutting line 18 without cracking during cutting.

[0038] Specifically include the following steps:

[0039] (1) half-cut the LED chip with a diamond cutting knife of a cutting machine, and the half-cut depth is 25 μm to 250 μm to form a cutting li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com