Manufacturing method of N-type solar battery

A technology of solar cells and manufacturing methods, applied in the manufacture of circuits, electrical components, final products, etc., can solve the problems of low photoelectric conversion efficiency, achieve the effect of improving photoelectric conversion efficiency and reducing metal impurities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

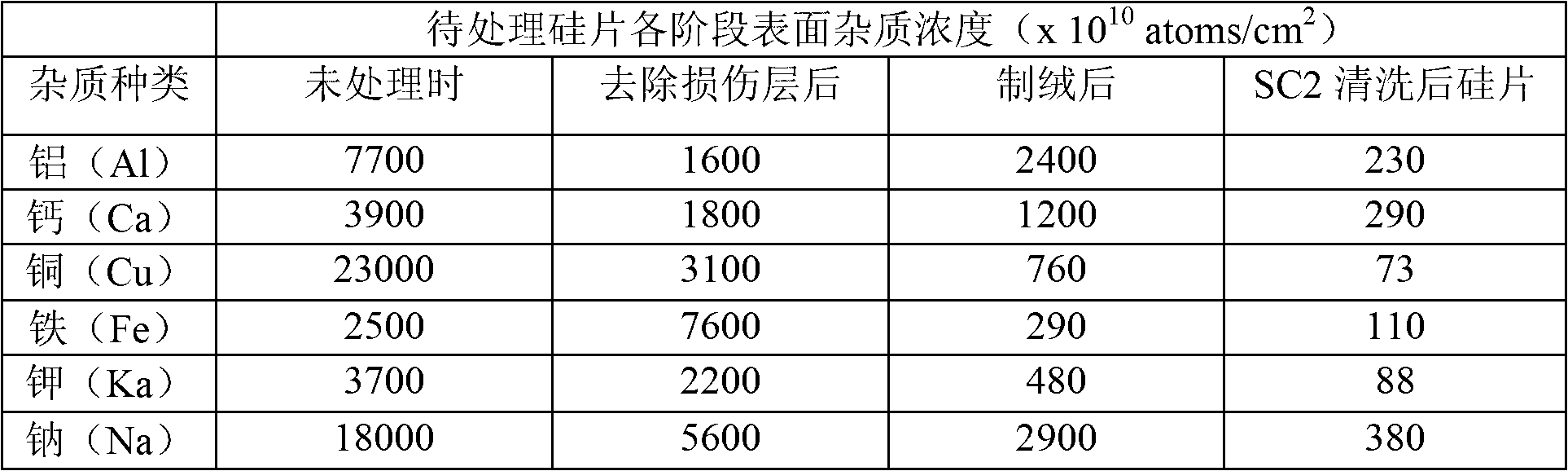

[0026] As described in the background technology, the photoelectric conversion efficiency of the existing N-type solar cells is relatively low. The inventors have found that the existing N-type solar cell manufacturing methods cannot effectively remove the metal impurities on the surface of the silicon wafer. When boron is diffused, it will diffuse into the silicon wafer in a high-temperature diffusion furnace, forming a carrier recombination center inside the silicon wafer, reducing the lifetime of minority carriers inside the silicon wafer, and further reducing the photoelectric conversion efficiency of the N-type solar cell.

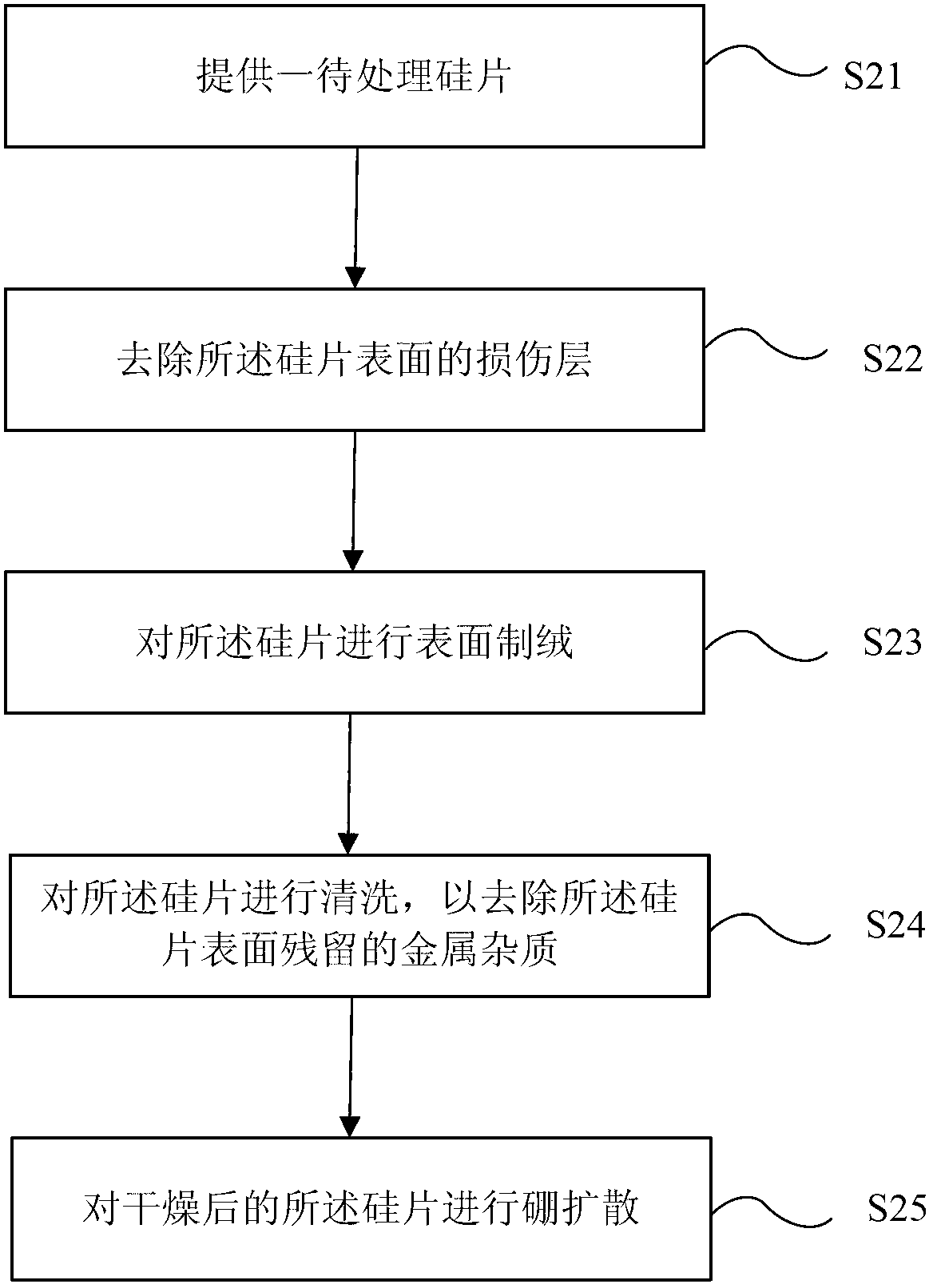

[0027] refer to figure 1 , figure 1 It is a schematic flow chart of a common N-type solar cell manufacturing method in the prior art, including:

[0028] Step S11: providing a silicon wafer to be processed.

[0029] Step S11: removing the damaged layer on the surface of the silicon wafer.

[0030] The silicon wafer to be treated is cleaned with a m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com