Integrated thermomagnetic system bracket of small circuit breaker and manufacturing method thereof

A technology of a small circuit breaker and a manufacturing method, which are applied in the direction of circuits, emergency protection device manufacturing, protection switch operation/release mechanism, etc., to achieve the effects of reducing the number of parts, improving system accuracy, and facilitating warehouse management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

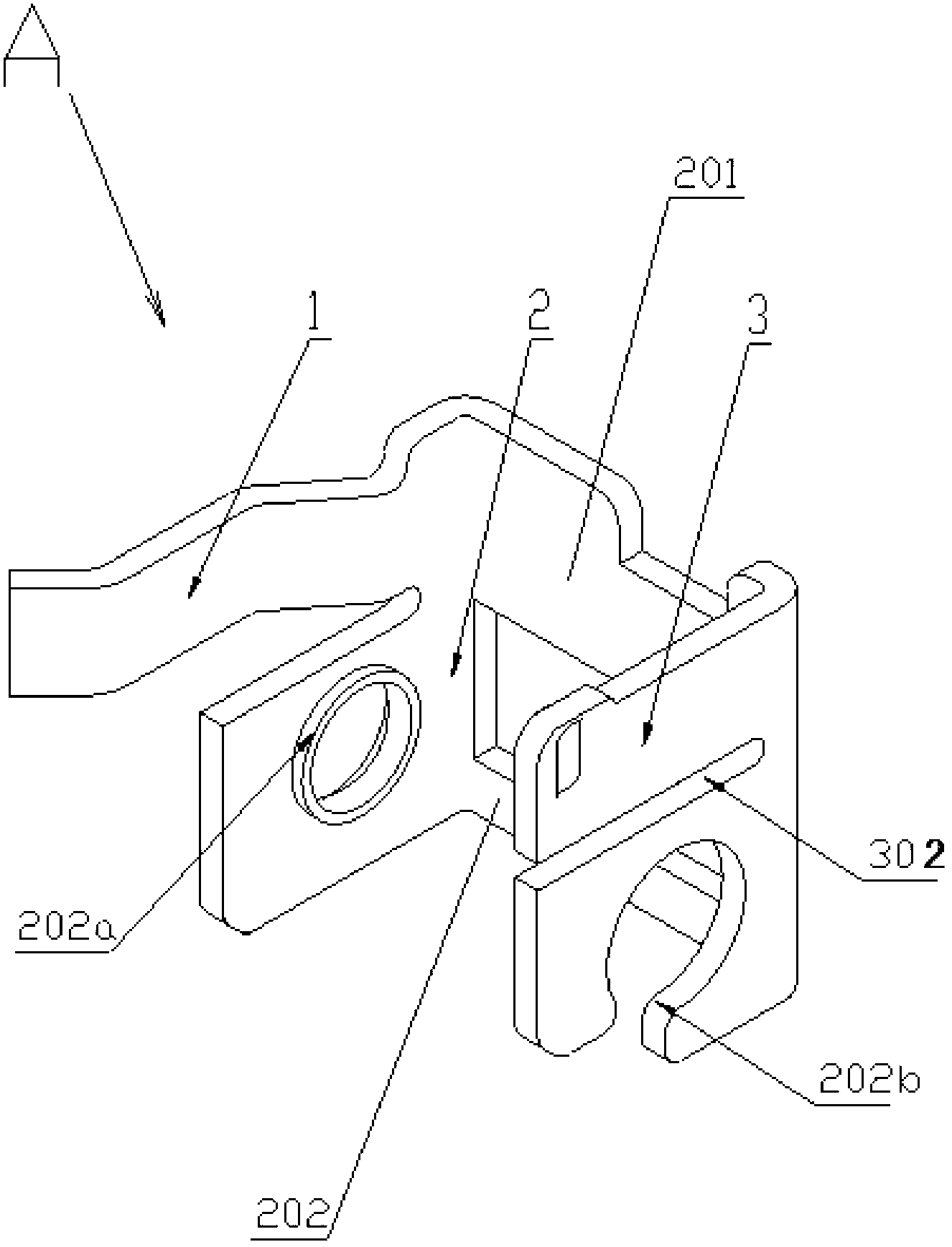

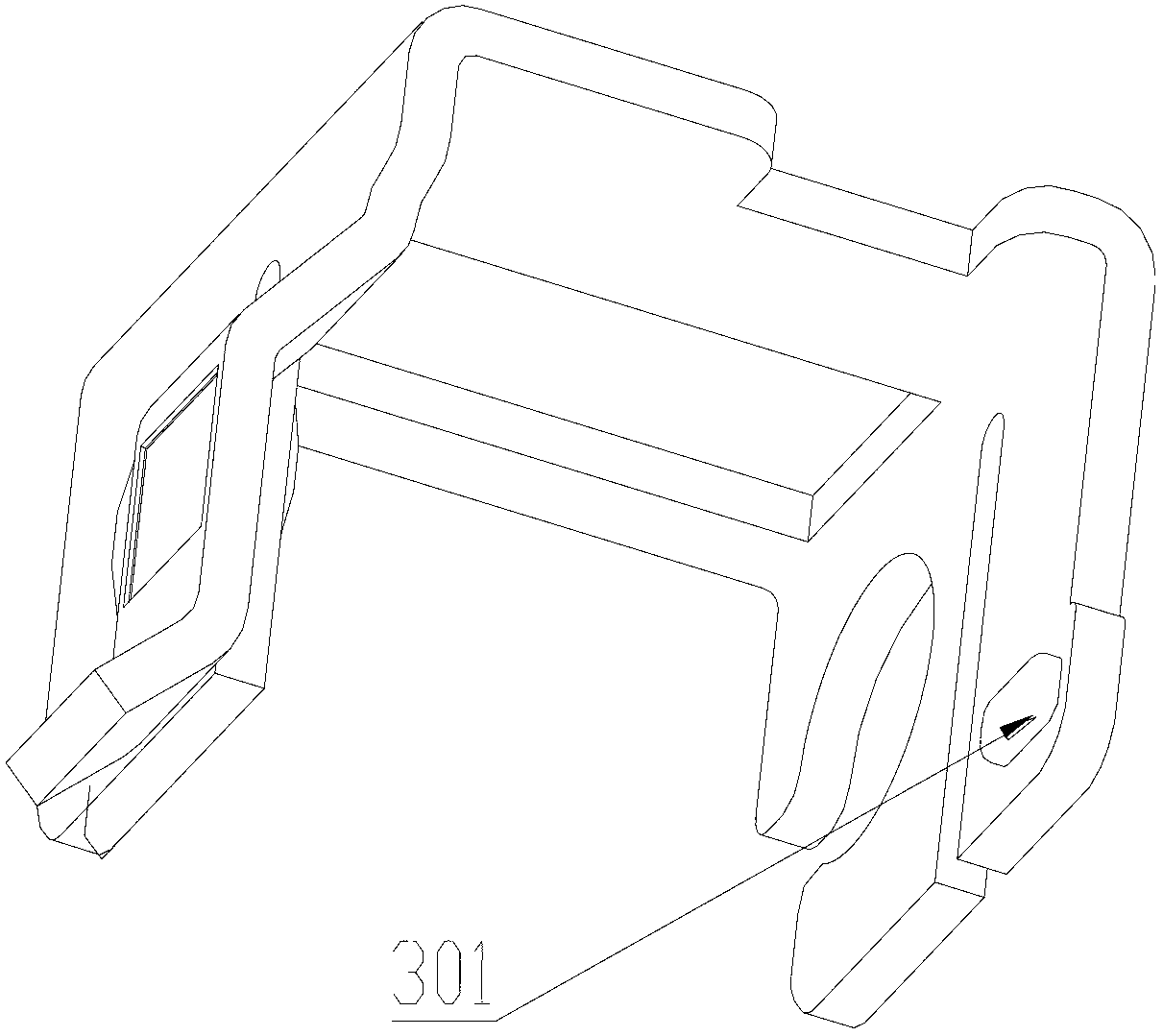

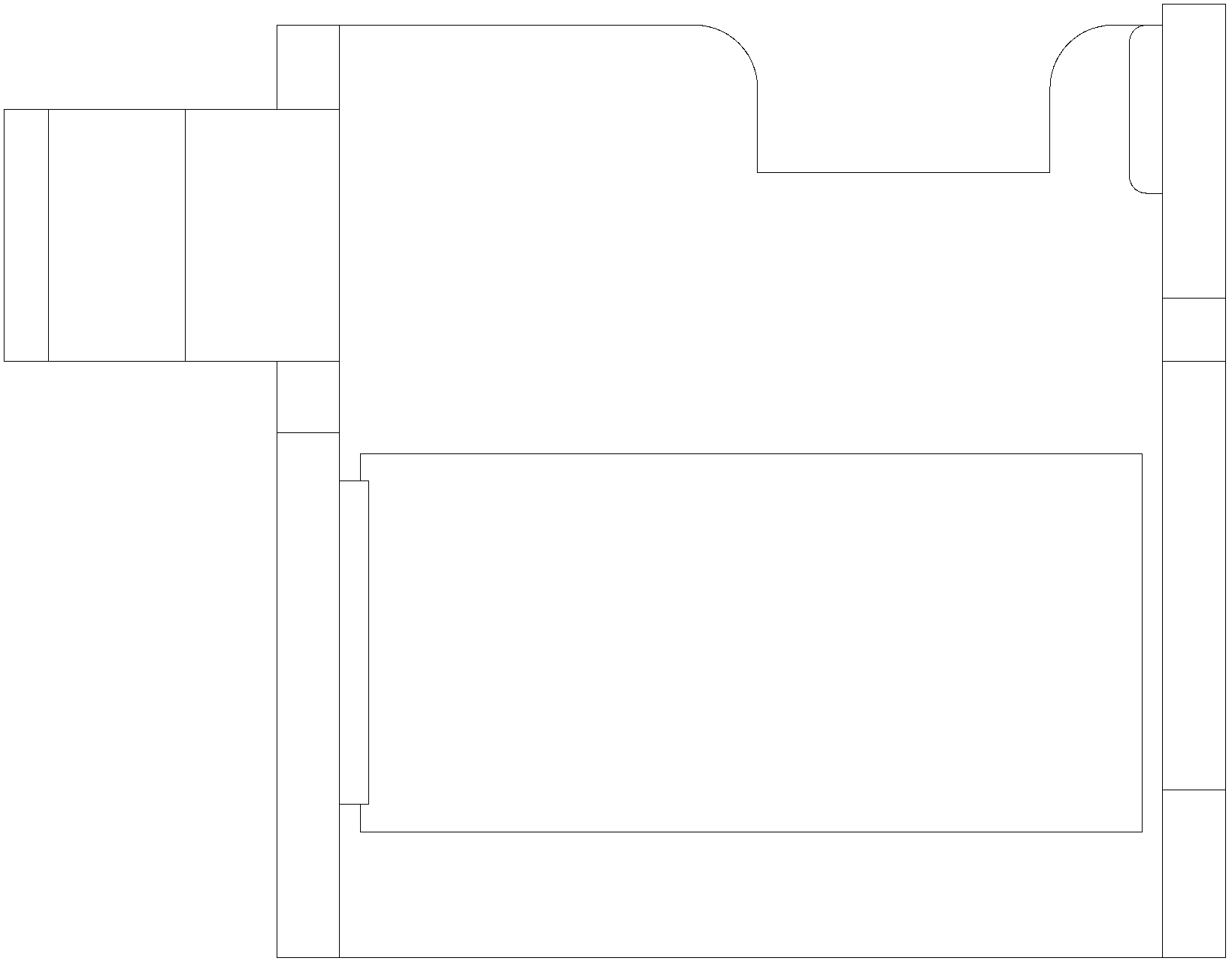

[0030] The first embodiment of the present invention, as attached figure 1 , 2 , 3 and 4, the integrated thermal-magnetic system bracket of the small circuit breaker provided by the present invention includes a static contact plate 1, a yoke 2 and a double gold positioning member 3, wherein the yoke 2 is located on the static contact plate 1 Between the double gold positioning part 3, and the static contact plate 1, the yoke 2 and the double gold positioning part 3 are in a U-shaped structure. The magnetic yoke 2 includes a conductive part 201 and a magnetic induction part 202. The material of the conductive part 201 is The metal conductive material copper plate T2, the material of the magnetic induction part 202 is a ferromagnetic material electrical pure iron plate DT3.

[0031] The static contact plate 1 and the double gold positioning part 3 are i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com