Offshore floating electric cable

A power cable and cable technology, applied in the cable field, can solve the problems of insufficient buoyancy, the cable can not meet the waterproof performance, etc., and achieve the effect of ensuring the performance of the mechanism, the uniform appearance quality, and the good resistance to oil and chemical solvent corrosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

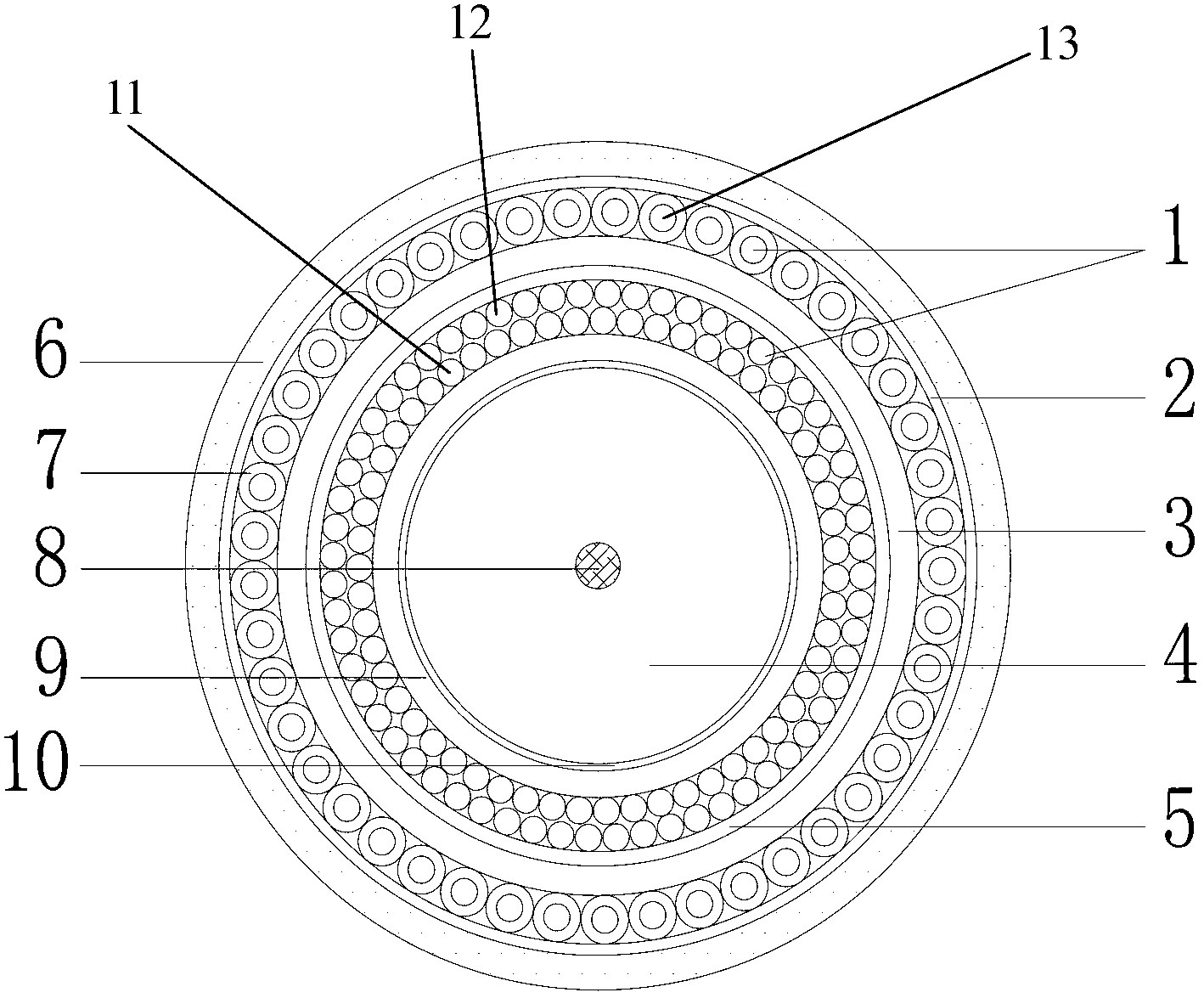

[0015] Such as figure 1 As shown, the offshore floating water power cable of the present invention mainly includes: a conductor 1, a first waterproof protective layer 2, a first thermoplastic vulcanizate (TPV) insulating layer 3, a float 4, a second waterproof protective layer 5, a polyurethane sheath 6, The second thermoplastic vulcanizate (TPV) insulating layer 7, reinforcing ribs 8, sealing layer 9, third waterproof protective layer 10, etc., wherein:

[0016] The center of the cable is a reinforcing rib 8, the outside of the reinforcing rib 8 is a float 4, the outside of the float 4 is a third waterproof protection layer 10, and the outside of the third waterproof protection layer 10 is a sealing layer 9, and on the outside of the sealing layer 9 The outside is two layers of conductors 1 uniformly arranged in a ring (the first layer conductor 11 and the second layer conductor 12, the first layer conductor 12 and the second layer conductor 1 are large cross-section power ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com