HCPN (Hierarchical Colored Petri Net)-based modeling method of iron making system logistic energy consumption model

A system logistics and energy consumption model technology, applied in the field of logistics energy consumption modeling research, to achieve the effect of improving the structure and simplifying the huge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

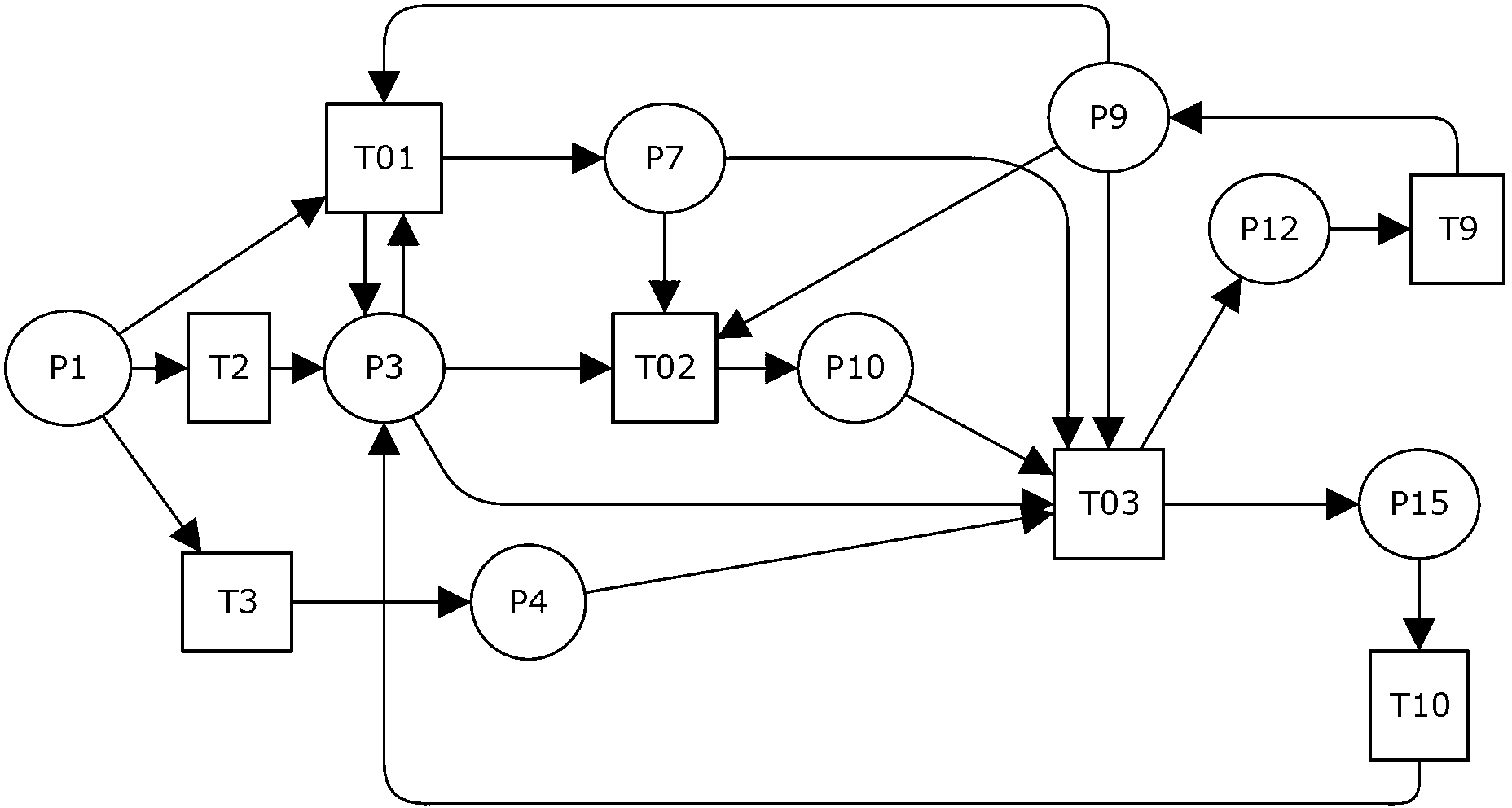

[0027] The ironmaking system mainly includes three parts: coking, sinter preparation, and blast furnace ironmaking. The main products of the first two processes, coke and sinter, are the main energy and raw materials for blast furnace ironmaking, supplemented by coal powder and raw ore. , pellets and other raw materials and energy, through the chemical reaction in the blast furnace, to obtain molten iron. According to the above process, the layered colored Petri net model of the ironmaking system is further established.

[0028] 1. According to the successive decomposition method, first establish a rough main Petri net for the ironmaking system, such as figure 1 As shown, it includes three major parts: coking T01, preparing sintering ore T02, and blast furnace ironmaking T03. Among them, the location identification and transition identification of each part are shown in Table 1 and Table 2.

[0029] Table 1 shows the places and their meanings in the built model

[0030] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com