Liquid crystal display panel and manufacturing method thereof, liquid crystal display

A technology for liquid crystal display panels and manufacturing methods, applied to static indicators, instruments, optics, etc., capable of solving problems such as different brightness of display panels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical problems, technical solutions, and advantages to be solved by the embodiments of the present invention clearer, a detailed description will be given below with reference to the drawings and specific embodiments.

[0054] The embodiments of the present invention provide a liquid crystal display panel, a manufacturing method thereof, and a liquid crystal display, which can not only simplify the manufacturing process of the liquid crystal display panel, but also solve the problem of the reflective area and transmission of the liquid crystal display panel in the transflective liquid crystal display mode. The brightness of the area is different.

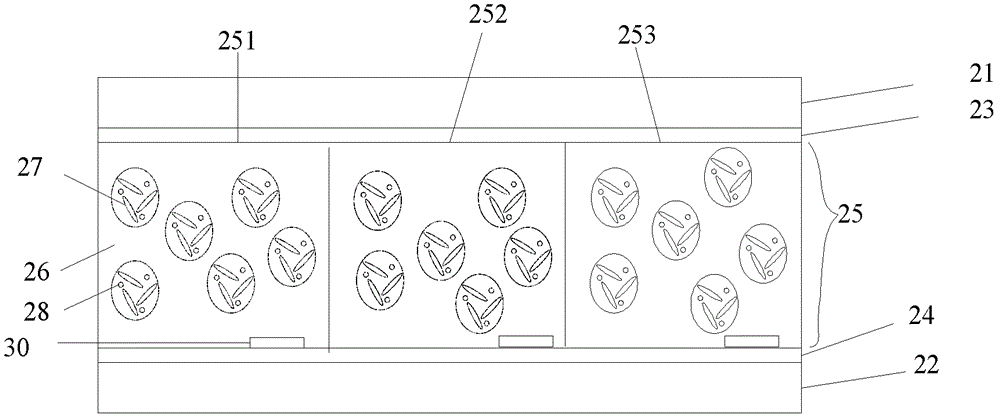

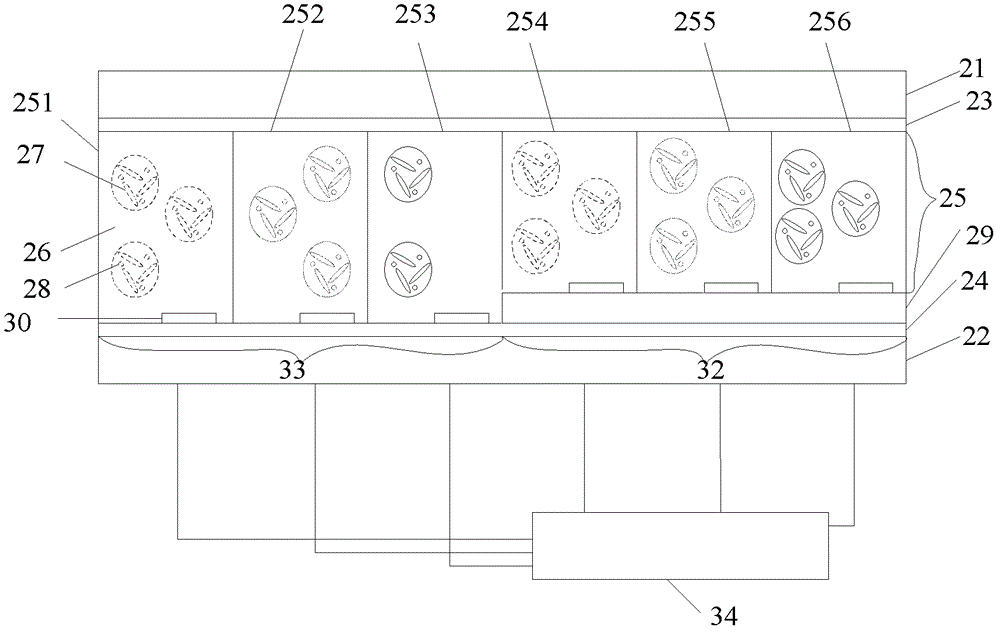

[0055] figure 1 It is a schematic structural diagram of a liquid crystal display panel provided by an embodiment of the present invention. The liquid crystal panel includes: a first substrate 22, a second substrate 21, a first transparent electrode 24 is provided on the first substrate, a second transparen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com