Calibration method and device based on laser induced plasma spectroscopy and method and device for measuring equivalent ratio of combustible gas to oxidant

A plasma spectroscopy and laser-induced technology, applied in the field of methods and devices, can solve the problems of difficult realization, complicated and expensive equipment, laser wavelength limitation, etc., and achieve the effects of low cost, simple signal processing, and high signal-to-noise ratio.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] The specific embodiment one, based on the calibration method of laser-induced plasma spectrum, it is realized by the following steps:

[0033] Step A, passing combustible gas, oxygen and nitrogen into the gas mixing tank to form a mixed gas, and controlling the flow of combustible gas, oxygen and nitrogen respectively;

[0034] Step B, passing the mixed gas formed in step A into the quartz glass round tube, and allowing the mixed gas to flow out from the nozzle of the quartz glass round tube;

[0035] Step C, using a laser to emit a laser beam, and focusing the laser beam to the position of the nozzle in step B, breaking through the mixed gas flowing out of the nozzle to generate plasma, and the plasma emits a fluorescent signal;

[0036] Step D, focusing the fluorescent signal emitted by the plasma in step C to the entrance of the optical fiber with a focusing lens, and the optical fiber transmits the incident optical signal at the entrance to the spectrometer; using a...

specific Embodiment approach 2

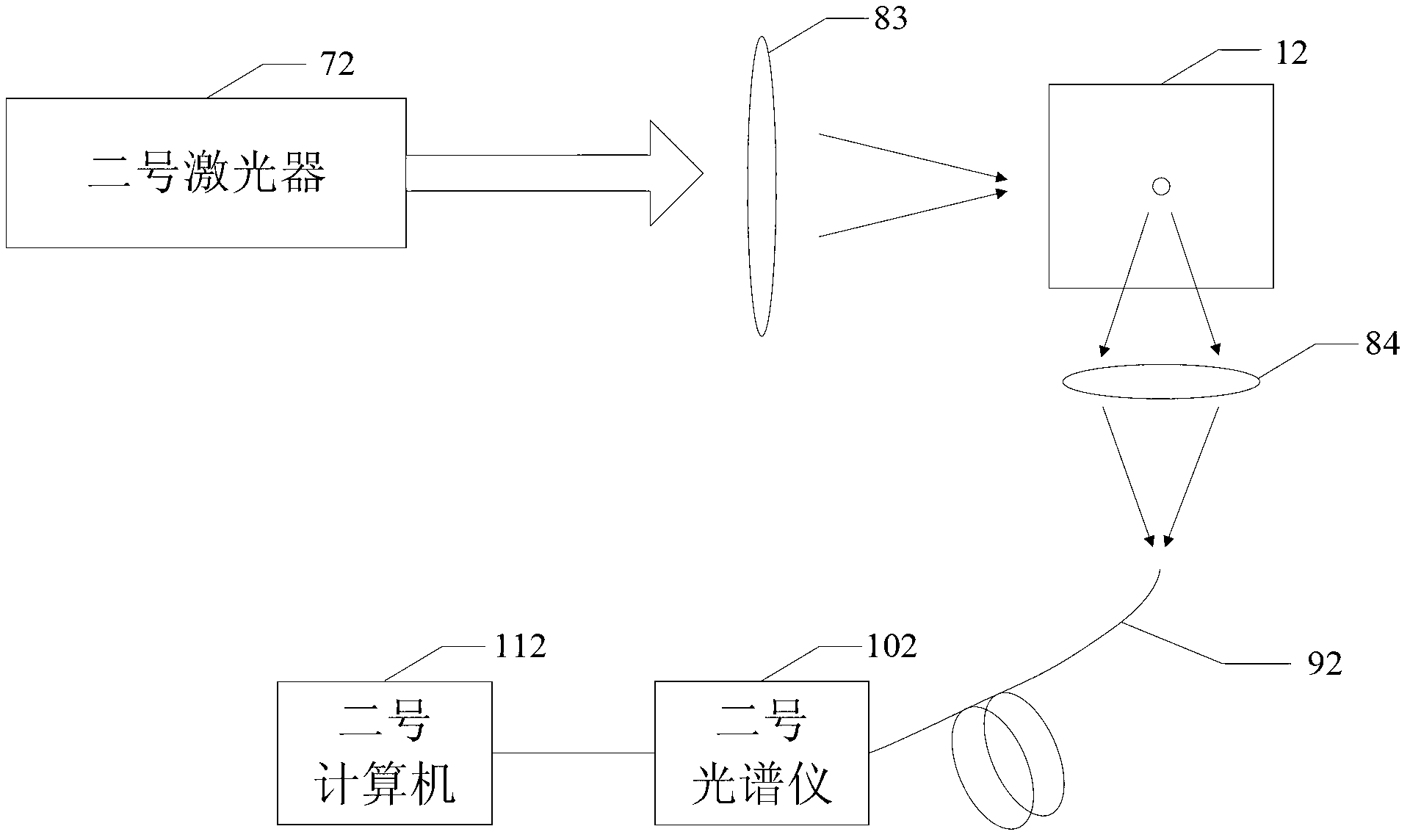

[0044] Specific embodiment two, realize the calibration device based on the laser-induced plasma spectrum of specific embodiment one, it comprises fuel gas bottle 1, oxygen gas bottle 2, nitrogen gas bottle 3, No. 1 flow meter 41, No. 2 flow meter 42 , No. 3 flow meter 43, gas mixing tank 5, quartz glass circular tube 6, No. 1 laser device 71, No. 1 focusing lens 81, No. 2 focusing lens 82, No. 1 optical fiber 91, No. 1 spectrometer 101 and No. 1 computer 111;

[0045] Fuel gas cylinder 1 is charged with combustible gas, oxygen gas cylinder 2 is filled with oxygen, and nitrogen gas cylinder 3 is filled with nitrogen; the gas outlet of fuel gas cylinder 1, the gas outlet of oxygen gas cylinder 2 and nitrogen gas cylinder 3 The gas outlets of the gas outlets are respectively communicated with the three air inlets of the gas mixing tank 5; the No. 1 flowmeter 41, the No. 2 flowmeter 42 and the No. 3 flowmeter 43 are arranged on the gas outlet of the fuel gas cylinder 1 and the ox...

specific Embodiment approach 3

[0047] Specific embodiment three, based on the method for measuring the equivalent ratio of combustible gas and oxidant based on laser-induced plasma spectroscopy in specific embodiment one, it is realized by the following steps:

[0048] Step 1, using a laser to emit a laser beam, focusing the laser beam into the target burner, breaking through the combustible gas and oxidant to be measured in the target burner, and generating plasma; the plasma emits a fluorescent signal;

[0049] Step 2. Focus the fluorescent signal emitted by the plasma in step 1 into the optical fiber with a focusing lens, and transmit it to the spectrometer through the optical fiber, and use a computer to analyze the fluorescent signal collected by the spectrometer to obtain the plasma spectrum of the combustible gas and oxidant to be measured;

[0050] Step 3. Obtain the H characteristic peaks and O characteristic peaks in the plasma spectrum of the combustible gas and oxidant to be measured in step 2, c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com