Real-time on-line detection device for working state of cannon photoelectric subsystem

A technology of working status and detection devices, which is applied in the direction of weapon testing, weapon accessories, offensive equipment, etc., can solve problems such as fault location, long repair time, debugging, poor real-time detection, heavy CPU load, etc., and is conducive to real-time online diagnosis , quickly and accurately locate faults, and reduce CPU load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

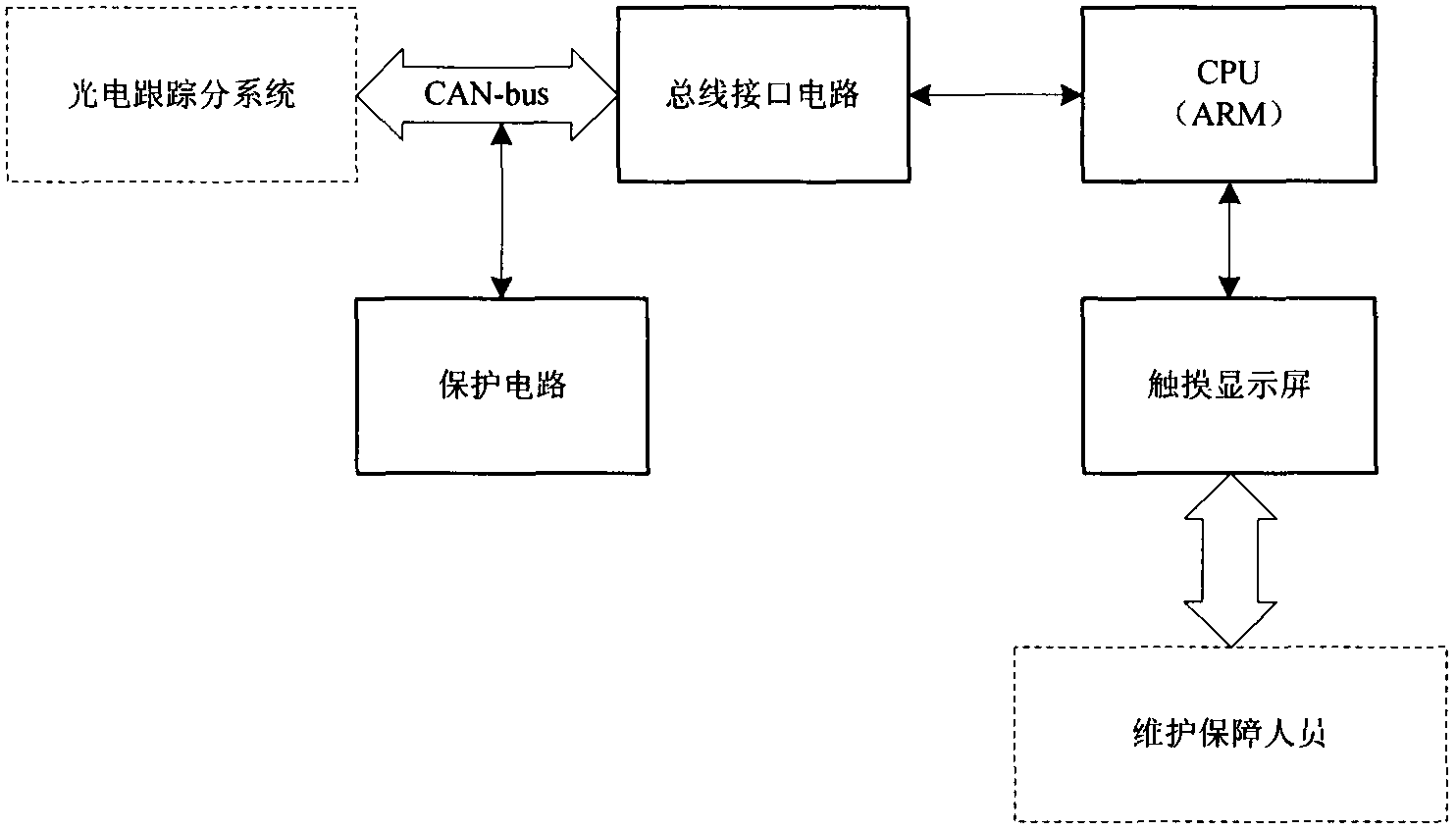

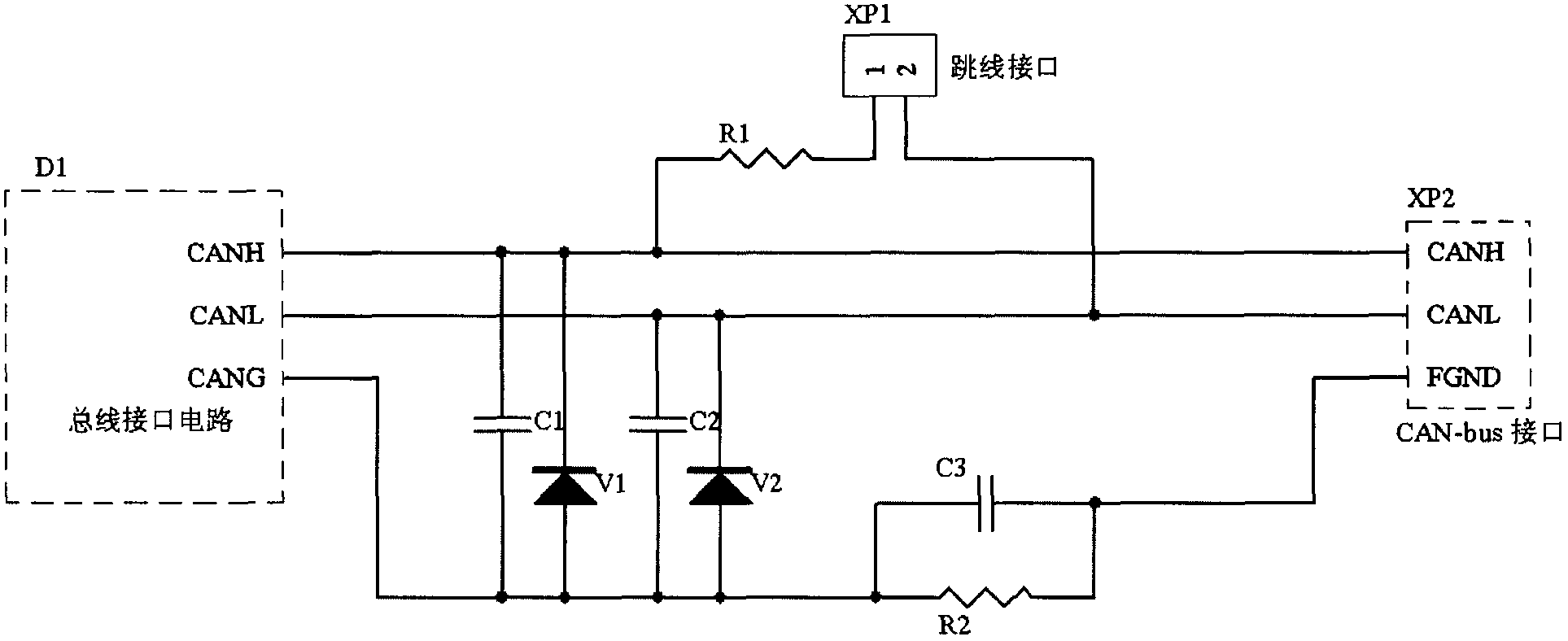

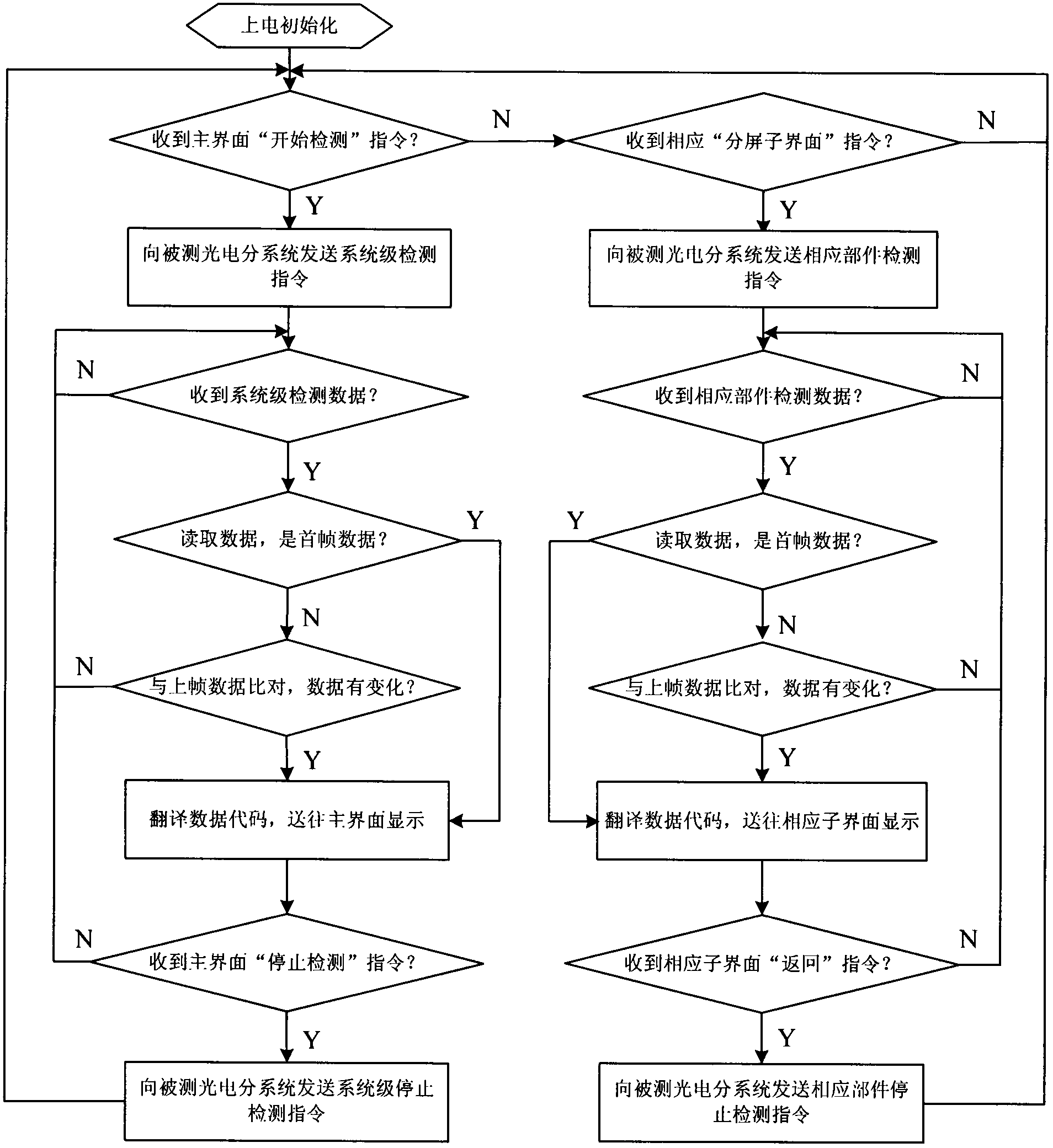

[0015] as figure 1 As shown, the preferred embodiment of the portable real-time online detection device of the present invention adopts the embedded hardware platform with ARM9 as the core, and it includes the CPU, bus interface circuit D1, jumper interface XP1, CAN-bus bus interface XP2, which model is LPC3250, Display, protection circuit. The display adopts a 6.4-inch TFT color LCD touch screen with a resolution of 640x480. The CPU and the bus interface circuit D1 are integrated on a circuit board. -bus bus interface XP2, which can realize the connection with the external power supply and the CAN-bus bus detection interface of the photoelectric subsystem. The original cable connection of the photoelectric subsystem does not need to be changed, and the online detection device of the present invention will not affect the work of ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com