Air humidification cabinet and use method thereof

A technology of air humidification and water-receiving plate, which is applied in the field of daily necessities and can solve the problem of inability to humidify indoor air.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

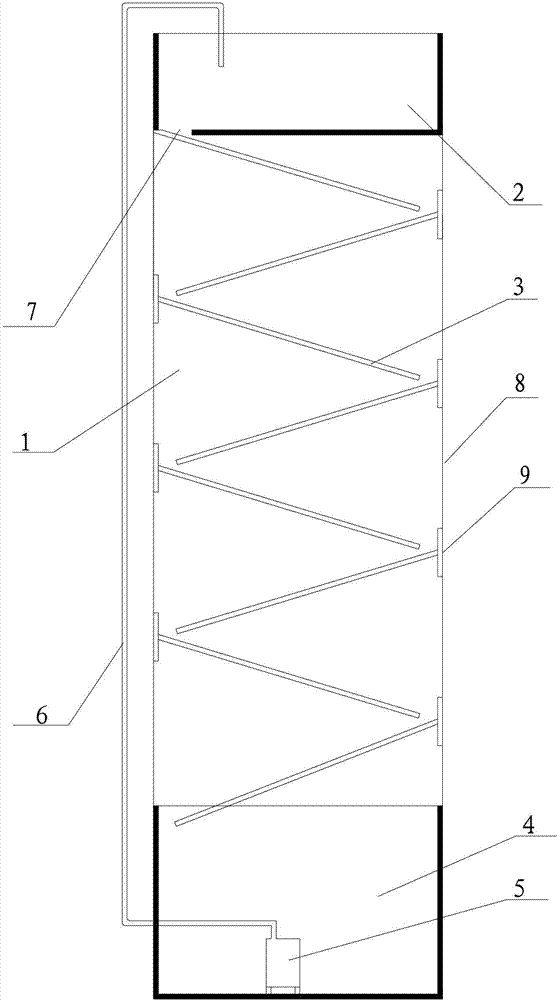

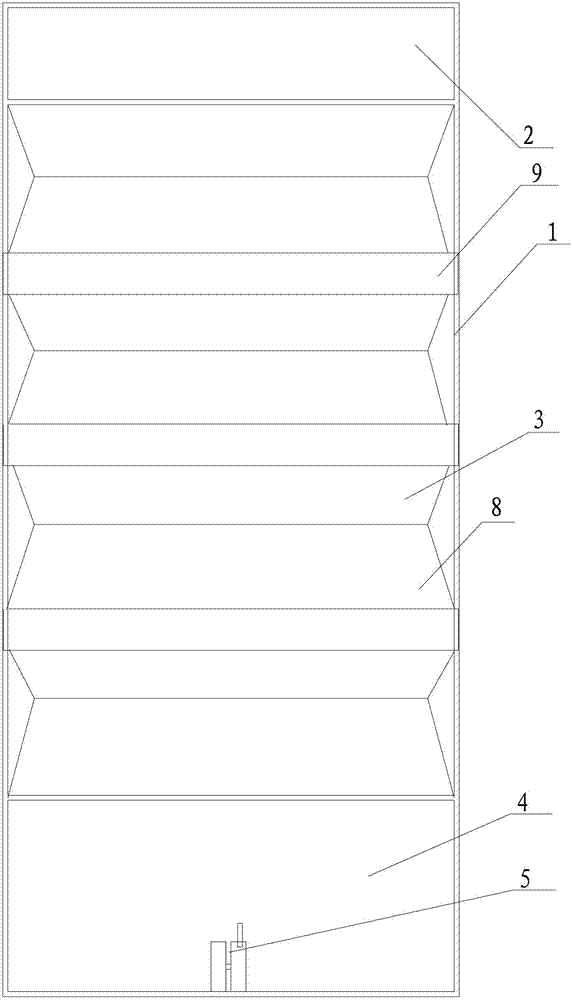

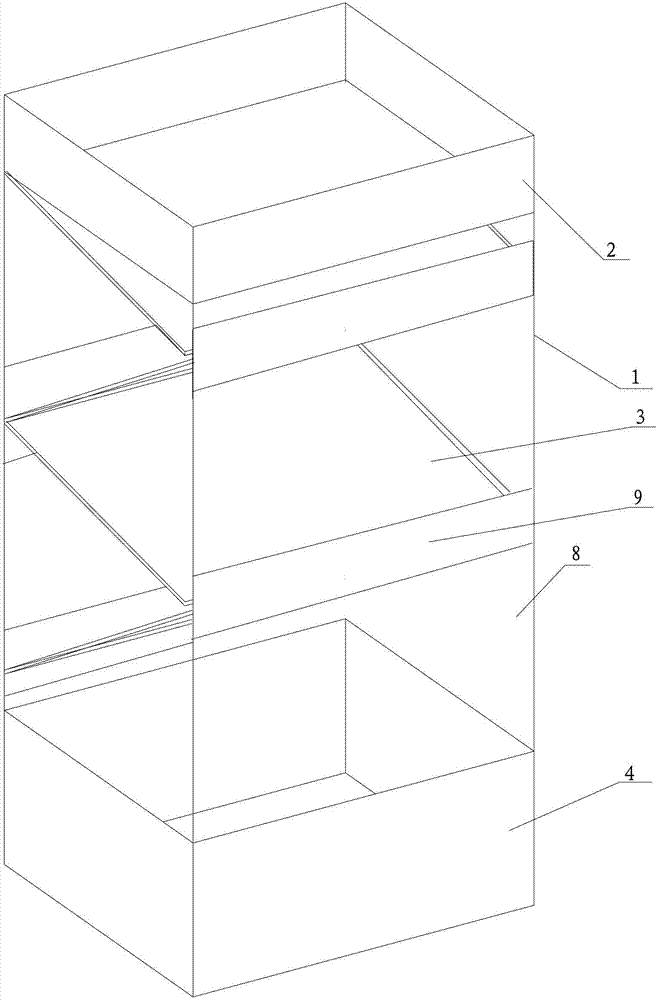

[0067] Air humidifying cabinet of the present invention, as figure 1 , 2 As shown in and 3, the first water tank 2 is located at the top of the frame body 1, the second water tank 4 is located at the bottom of the frame body 1, and the first water tank 2 is connected with a water pipe 6 for water inlet ;

[0068] The bottom of the first water tank 2 is provided with a water outlet 7;

[0069] There are multiple water bearing plates 3, one side of the water bearing plate 3 is fixed on the side wall 9 of the frame body 1, the side wall is provided with a plurality of evaporation ports 8, two adjacent In the water bearing plate 3, the projection on the horizontal plane of the water bearing plate 3 on the upper side away from the side wall connected to it is within the range of the horizontal projection of the water bearing plate 3 below it Inside, fix the distance between the side wall 9 of the water bearing plate 3 and the side wall opposite to it, and the length ratio of the...

specific Embodiment 2

[0074] In the air humidifying cabinet of the present invention, the first water tank 2 is located on the top of the frame body 1, the second water tank 4 is located at the bottom of the frame body 1, and the first water tank 2 is connected to the water pipe for water inlet. 6 connections;

[0075] The bottom of the first water tank 2 is provided with a water outlet 7;

[0076] There are multiple water bearing plates 3, one side of the water bearing plate 3 is fixed on the side wall 9 of the frame body 1, the side wall is provided with a plurality of evaporation ports 8, two adjacent In the water bearing plate 3, the projection on the horizontal plane of the water bearing plate 3 on the upper side away from the side wall connected to it is within the range of the horizontal projection of the water bearing plate 3 below it Inside, fix the distance between the side wall 9 of the water bearing plate 3 and the side wall opposite to it, and the length ratio of the horizontal projec...

specific Embodiment 3

[0081] In the air humidifying cabinet of the present invention, the first water tank 2 is located on the top of the frame body 1, the second water tank 4 is located at the bottom of the frame body 1, and the first water tank 2 is connected to the water pipe for water inlet. 6 connections;

[0082] The bottom of the first water tank 2 is provided with a water outlet 7;

[0083] There are multiple water bearing plates 3, one side of the water bearing plate 3 is fixed on the side wall 9 of the frame body 1, the side wall is provided with a plurality of evaporation ports 8, two adjacent In the water bearing plate 3, the projection on the horizontal plane of the water bearing plate 3 on the upper side away from the side wall connected to it is within the range of the horizontal projection of the water bearing plate 3 below it Inside, fix the distance between the side wall 9 of the water bearing plate 3 and the side wall opposite to it, and the length ratio of the horizontal projec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com