Universal-type statically indeterminate hydraulic support

A hydraulic support and ultra-statically indeterminate technology, applied in mine roof support, mining equipment, earthwork drilling, etc., can solve the problems of high labor intensity, low efficiency, long production cycle, etc., to reduce production costs, use convenient and reliable, Reduce the effect of intermediate links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

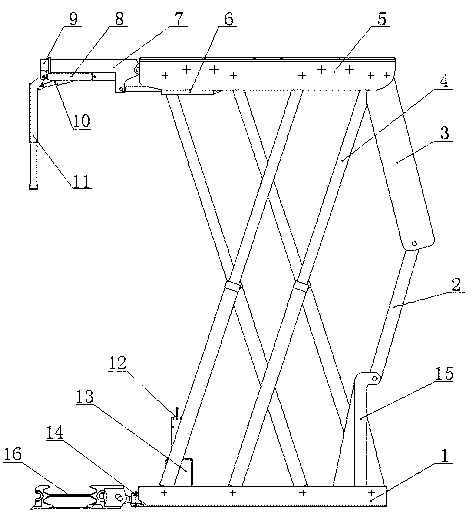

[0012] Below in conjunction with accompanying drawing, one embodiment of the present invention is further described:

[0013] like figure 1 As shown, the general-purpose hyperstatic hydraulic support of the present invention is mainly composed of a base 1, a connecting plate 2, a tail beam 3, eight hydraulic columns 4, a top beam 5, a front beam jack 6, a front beam 7, and a telescopic beam jack 8 , telescopic beam 9 , support plate jack 10 , support plate 11 , hydraulic control valve assembly 12 , bridge box 13 , push device 14 , and elevated frame 15 . The top beam 5 , the front beam 7 , the telescopic beam 9 , the guard plate 11 , the tail beam 3 , the connecting plate 2 , the base 1 , the bridge box 13 , and the elevated frame 15 are welded by steel plates or profiled steels. The hydraulic control valve assembly 12 is composed of a group of manually operated valves or electro-hydraulic remote control valves, one-way valves, pipe fittings and seals. remote control. The e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com