Novel single-leaf push-pull sealing window with welded mullion and manufacturing method of novel single-leaf push-pull sealing window

A sealing window, a new type of technology, applied in the direction of sealing device, leaf arrangement, leaf frame, etc., can solve the problems of waste of raw materials, large thickness and shape of three-track sliding window frame, difficult to seal, etc., to reduce thickness and save Raw materials, the effect of saving manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

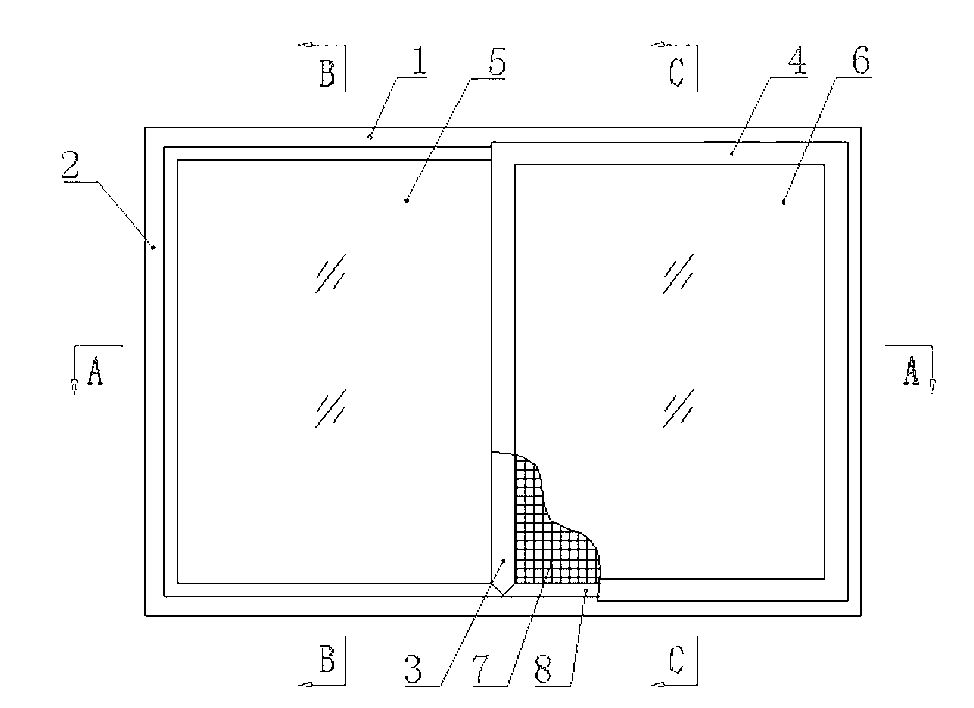

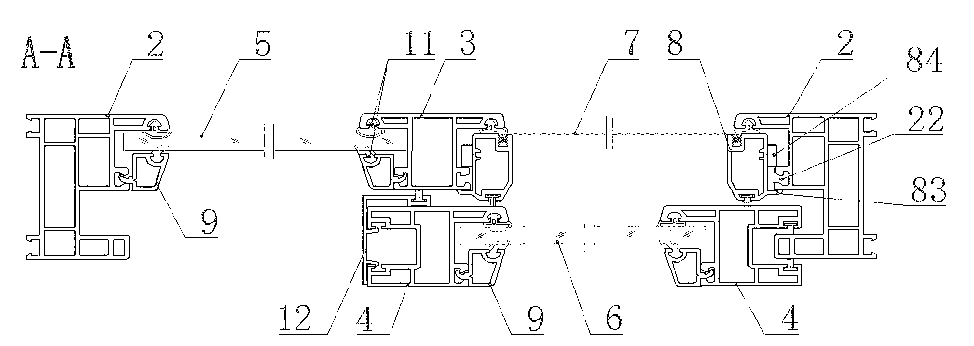

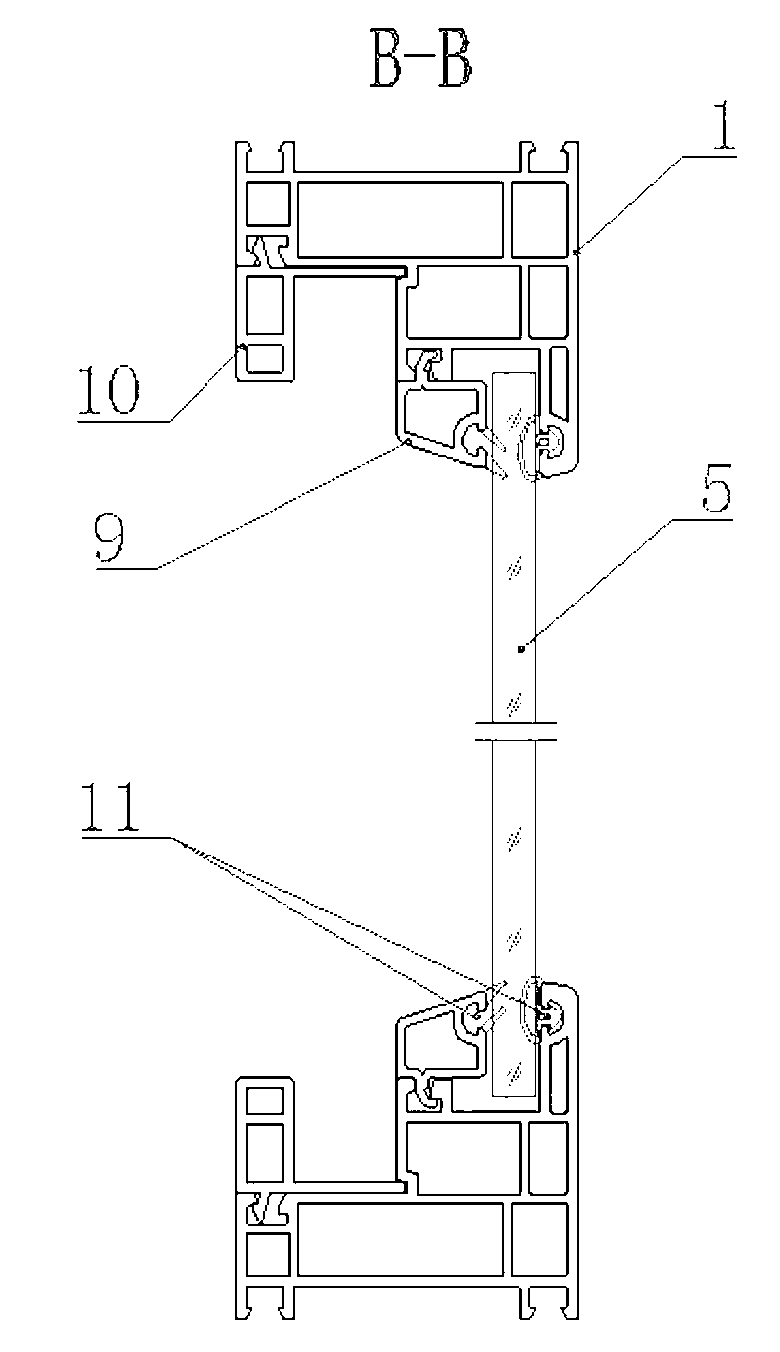

[0058] see Figure 1 to Figure 20 , the present invention is a novel single-leaf push-pull sealed window with stile welding, including a window frame and a push-pull sash 4, the window frame is composed of two upper and lower horizontal frames 1, two left and right vertical frames 2 and a middle stile 3. The upper and lower ends of the stile 3 are welded to the upper and lower horizontal frames 1 respectively, and the two ends of the horizontal frame 1 are respectively welded to the upper and lower ends of the vertical frame 2 to form two rectangular spaces, and the inner peripheral surfaces of the two rectangular spaces are The outer half is a fixed layer, and a fixed glass 5 and a gauze fan (made up of a gauze 7 and a gauze fan frame 8) are installed respectively. A separate fan rail 10 is installed on the inner half of the two horizontal frames 1, and a fan rail 10 corresponding to the fan rail 10 (same cross-sectional structure) and integrated with the vertical frame 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com