Composite yarn compounded by double yarns through using filament screens to cover downwards and support upwards, spinning method and application

A technology of composite yarn and screen, applied in the field of composite yarn, can solve the problems of unusable spinnability and poor fiber, etc., and achieve the effect of practical mechanism, high breaking strength and tear strength, and stable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

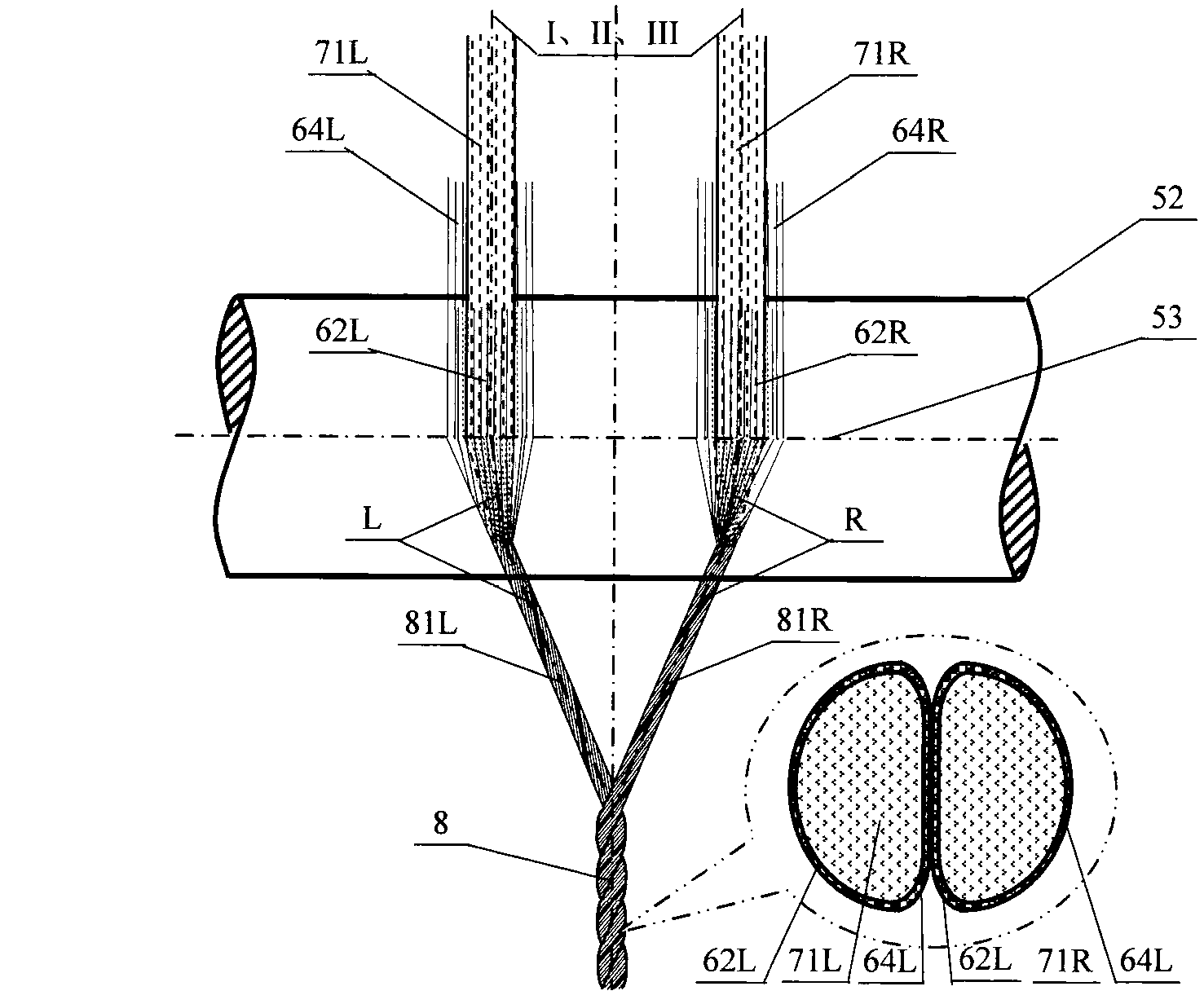

[0053] Example 1: Recycled cotton (noil) and viscose filament double-wrapped / double-wrapped composite spinning

[0054] Adopt the compound spinning method of the present invention to be used for the double-yarn composite of screen upper cover and lower support, four strands of viscose long filaments are spread according to the above-mentioned method for spreading yarns on the upper cover and lower support of the screen, and then at the nip of the front roller and the back Cotton fiber strands are used for double net wrapping / double net wrapping composite spinning to form a smooth composite yarn. The specific process parameters are shown in the table below. The spun yarn is as follows: figure 1 shown. The yarn hairiness index, twist angle, breaking strength, breaking elongation and yarn fineness irregularity of the spun bright and clean composite yarn are listed in the table below. Among them, the spinning rate is very high, which means that there is very little loss of fiber ...

Embodiment 2

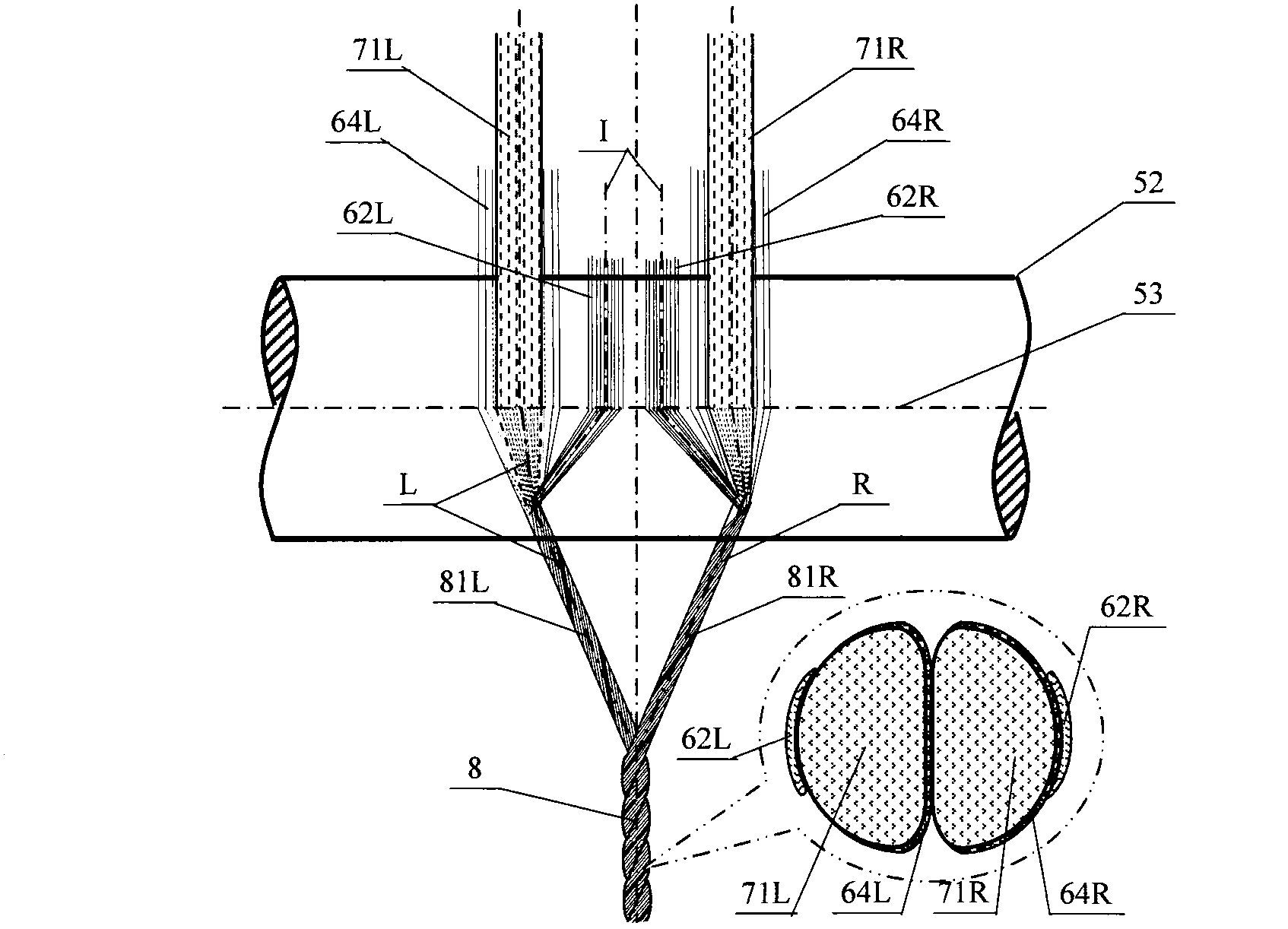

[0055] Example 2: Composite spinning of short wool and silk net wrapping / net wrapping

[0056] Adopt the compound spinning method that is used for double-yarn compounding on the screen upper cover and lower support of the present invention, spread the four strands of silk filament bundles according to the above-mentioned silk upper cover lower support yarn spreading method, and then at the front roller nip place and short wool The fiber strands are net-wrapped / net-wrapped composite spinning to form a smooth composite yarn. The specific process parameters are shown in the table below. The spun yarn is as follows: figure 2 shown. The yarn hairiness index, twist angle, breaking strength, breaking elongation and yarn fineness irregularity of the spun bright and clean composite yarn are listed in the table below. Among them, the spinning rate is very high, which means that there is very little loss of fiber such as flying flowers, shavings, and broken ends; Low, indicating good ...

Embodiment 3

[0057] Embodiment 3: composite spinning of kapok / PTT filament net-wrapped bag / net-wrapped bag

[0058] Adopt the compound spinning method that is used for the compound spinning of double yarn compound under the cover on the screen of the present invention, the four strands of PTT long filament bundle are carried out yarn spreading by the above-mentioned method of spreading the yarn under the cover on the screen under the support, and then at the front roller nip place and kapok fiber The strands are net-wrapped / net-wrapped composite spinning to form a smooth composite yarn. The specific process parameters are shown in the table below. The spun yarn is as follows: image 3 shown. The yarn hairiness index, twist angle, breaking strength, breaking elongation and yarn fineness irregularity of the spun bright and clean composite yarn are listed in the table below. Among them, the spinning rate is very high, which means that there is very little loss of fiber such as flying flowers, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com