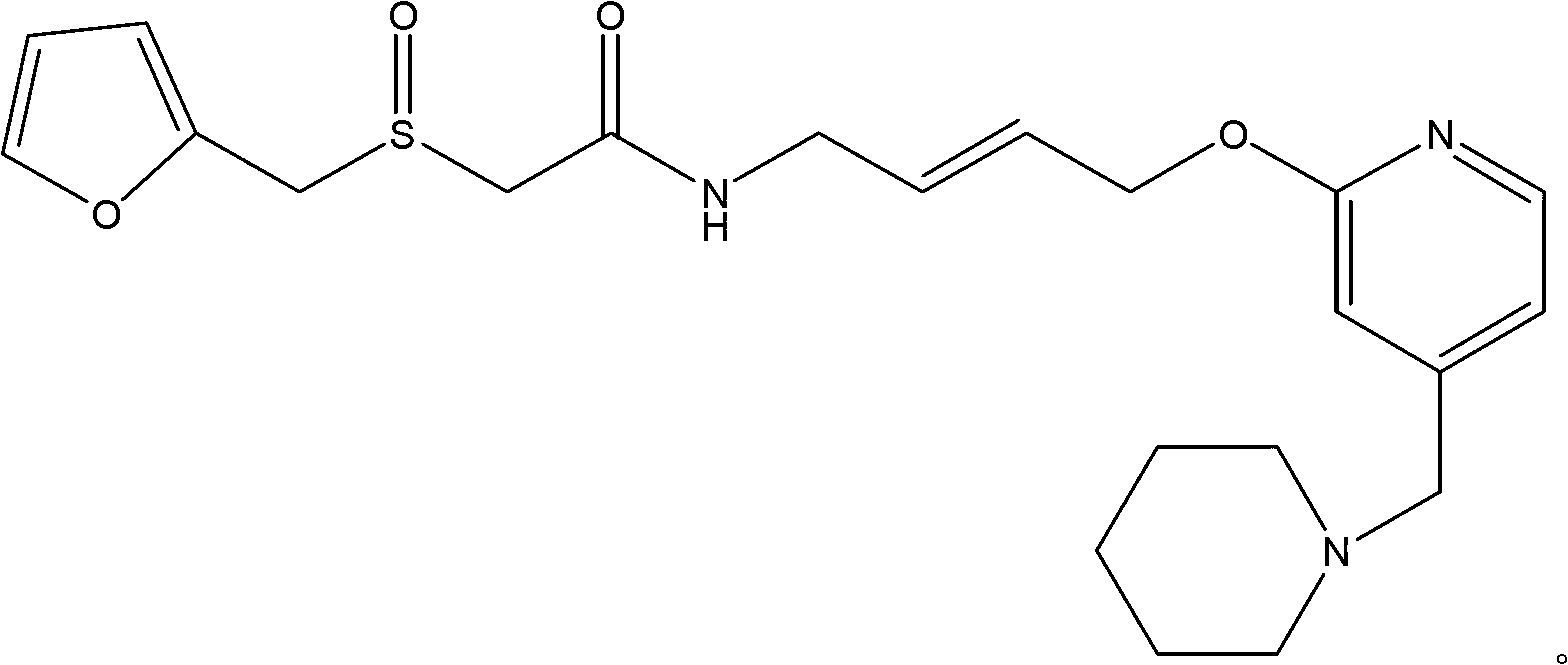

Lafutidine compound and novel preparation method of lafutidine compound

A technology of lafutidine and compounds, which is applied in the field of lafutidine compounds, can solve the problems of low purity of lafutidine, and achieve the effects of easy industrial production, improved product quality, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

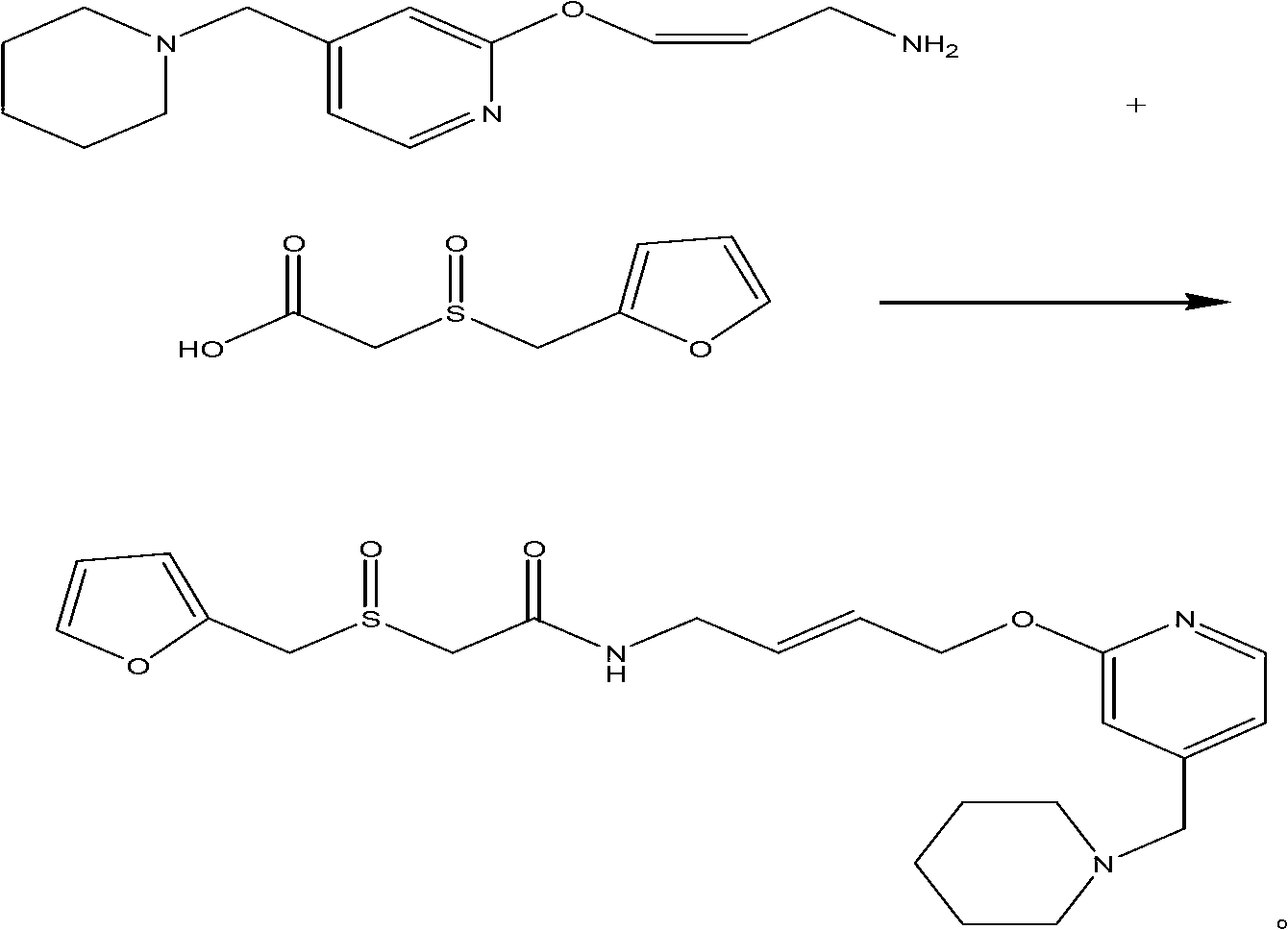

Method used

Image

Examples

Embodiment 1

[0048] Take 10g of lafutidine raw material with a long production date (Sichuan Xinyuan Pharmaceutical Co., Ltd., batch number 100908), and the purity is 95.48% as measured by high performance liquid chromatography. The lafutidine raw material was dissolved in 100ml of ethyl acetate, fully stirred to make it completely dissolved, filtered to remove insoluble impurities, and the filtrate was collected once.

[0049] Add 0.2 g of activated carbon to the primary filtrate, stir and adsorb at 40°C for 15 minutes, filter the deactivated carbon, collect the secondary filtrate, and concentrate under reduced pressure at 60°C.

[0050] The above-mentioned concentrated filtrate was heated to a temperature of 70-75° C., kept for half an hour, and then a mixed solvent comprising 50% of the volume of the solution was added with a volume ratio of 0.3:1 of ethanol and water. First cool down to 55°C at a speed of 2°C / hour, then cool down to 20°C at a speed of 4°C / hour, and then cool down to 2°...

Embodiment 2

[0053] Take 10 g of expired lafutidine raw material (Qingdao Guofeng Pharmaceutical Co., Ltd., batch number 20080501), and the purity measured by high performance liquid chromatography is 92.20%. The lafutidine raw material was dissolved in 70ml of toluene, fully stirred to make it completely dissolved, filtered to remove insoluble impurities, and the filtrate was collected once.

[0054] Add 0.3 g of alumina to the primary filtrate, stir and adsorb at 35°C for 10 minutes, filter the de-alumina, collect the secondary filtrate, and concentrate under reduced pressure at 55°C.

[0055] Heat the above-mentioned concentrated filtrate to a temperature of 72-74°C and keep it for one hour, then add a mixed solvent of methanol and water with a volume ratio of 0.4:1 accounting for 40% of the solution volume, first at a speed of 2.5°C / hour Cool down to 55°C, then cool down to 20°C at a speed of 3°C / hour, and then cool down to 5°C at a speed of 5°C / hour, during which crystals slowly preci...

Embodiment 3

[0058] Take 10 g of the lafutidine crude product prepared according to EP0282077, and the purity is 93.25% as measured by high performance liquid chromatography. Dissolve the lafutidine raw material in 60ml of a 1:1 mixed solvent of hexane and cyclohexane, stir well to completely dissolve it, filter to remove insoluble impurities, and collect the filtrate once.

[0059] Add 0.2 g of A-type molecular sieve to the primary filtrate, stir and adsorb at 35°C for 15 minutes, filter and remove the molecular sieve, collect the secondary filtrate, and concentrate under reduced pressure at 60°C.

[0060] Bring the above-mentioned concentrated filtrate to a temperature of 70-72°C and keep it for half an hour, then add a mixed solvent of ethanol and water with a volume ratio of 0.4:1 accounting for 30% of the solution volume, and first cool down at a rate of 1.8°C / hour to 55°C, then lower the temperature to 20°C at a rate of 3°C / hour, and then lower the temperature to 5°C at a rate of 5.5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com