Formula of colored coating and application of formula

A color coating and formula technology, applied in the color coating formula and its application field, can solve problems such as hidden safety hazards, easy cracking of seams, installation difficulties, etc., and achieve the effects of cost saving, environmental protection cost, and beautiful appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

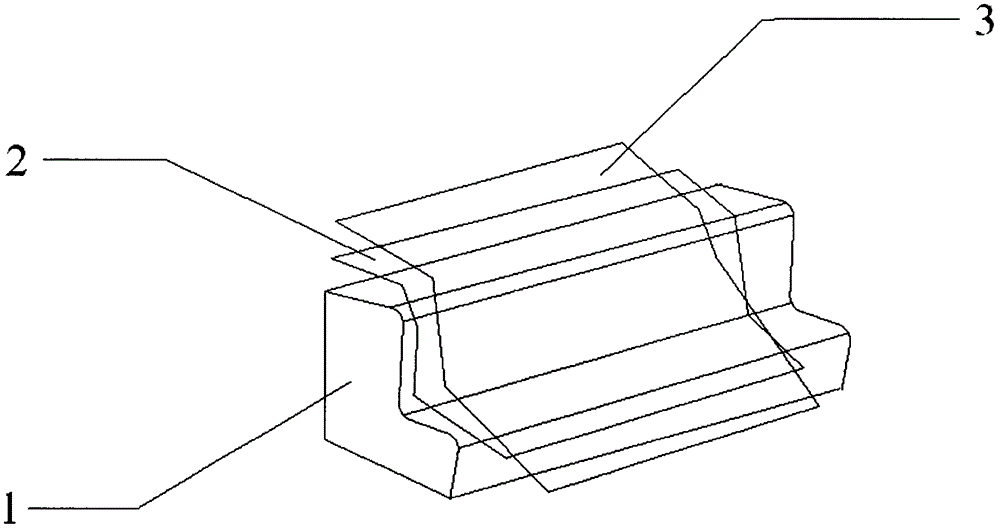

Image

Examples

Embodiment 1

[0033] A color coating formula, comprising the following components in parts by weight: white Portland cement 220, quartz sand 100, cellulose ether 1.5, wood fiber 1, PP fiber 3, organic silicon 3.5, heavy calcium 30 and rubber powder 60 , Also add the amount of pigment required by the product. When adding, the pigment is in the form of an emulsion, wherein the weight ratio of the emulsion to the mortar (that is, the total amount of white Portland cement and quartz sand) is 18:100.

[0034] Quartz sand is a mixture of No. 6 and No. 7. Adjust the thickness of the sand grains according to the needs of the coating.

[0035] The pigments are iron oxide red and a small amount of iron oxide black.

[0036] An application of the above-mentioned color coating formula on EPS for construction, the specific methods include:

[0037] Lay an anti-cracking mesh of 4*5mm grid on the EPS molded product for construction, and then coat a coating formula with a lot of coarse sand, with a thickn...

Embodiment 2

[0039] A color coating formula, comprising the following components by weight: white Portland cement 280, quartz sand 30, cellulose ether 3.5, wood fiber 1, PP fiber 3, organic silicon 1.5, heavy calcium 100 and rubber powder 28 , Also add the amount of pigment required by the product. When adding, the pigment is in the form of an emulsion, wherein the weight ratio of the emulsion to the mortar (that is, the total amount of white Portland cement and quartz sand) is 22:100.

[0040] White Portland cement is 52.5 white cement.

[0041] Quartz sand is a mixture of No. 6 and No. 7. Adjust the thickness of the sand grains according to the needs of the coating.

[0042] The pigments are iron oxide yellow and a small amount of iron oxide black.

[0043] An application of the above-mentioned color coating formula on EPS for construction, the specific methods include:

[0044] Lay an anti-cracking mesh of 4*5mm grid on the EPS molded product for construction, and then coat a coating ...

Embodiment 3

[0046] A color coating formula, comprising the following components in parts by weight: 250 parts by weight of white Portland cement, 80 parts of quartz sand, 3.0 cellulose ether, 3 parts of wood fiber, 1 part of PP fiber, 3.5 parts of organic silicon, 80 parts of heavy calcium and 35 parts of rubber powder , Also add the amount of pigment required by the product. When adding, the pigment is in the form of an emulsion, wherein the weight ratio of the emulsion to the mortar (that is, the total amount of white Portland cement and quartz sand) is 20:100.

[0047] Quartz sand is a mixture of No. 6 and No. 7. Adjust the thickness of the sand grains according to the needs of the coating.

[0048] The pigment is iron oxide yellow.

[0049] An application of the above-mentioned color coating formula on EPS for construction, the specific methods include:

[0050] Lay an anti-crack net with 4*5mm mesh on the line EPS molded product, and then apply a coating formula with more coarse san...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com