Pear-shaped hole equipped braking distribution valve for heavy-loaded long and large train

A technology of pear-shaped holes and distribution valves, applied in brakes, brake components, pneumatic brakes, etc., can solve the problems of slow decompression speed of train tubes, large longitudinal impulse of trains, strong braking ability, etc., and achieve simple realization method , reduce the vertical impulse, improve the effect of consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

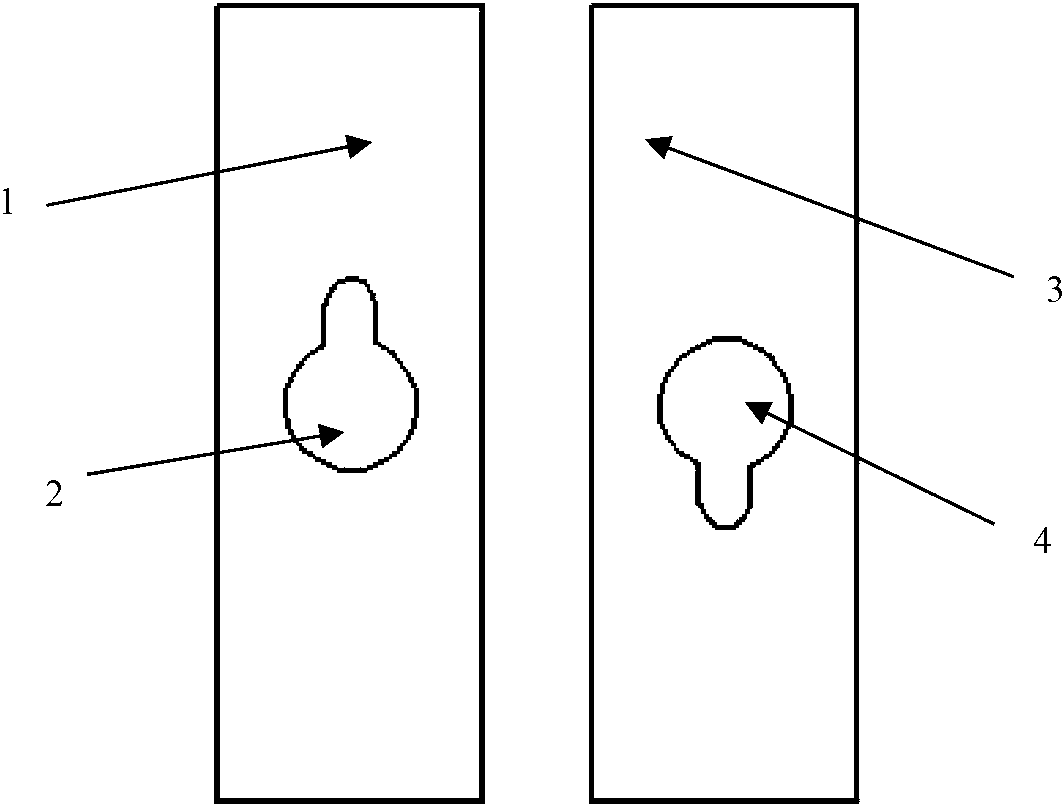

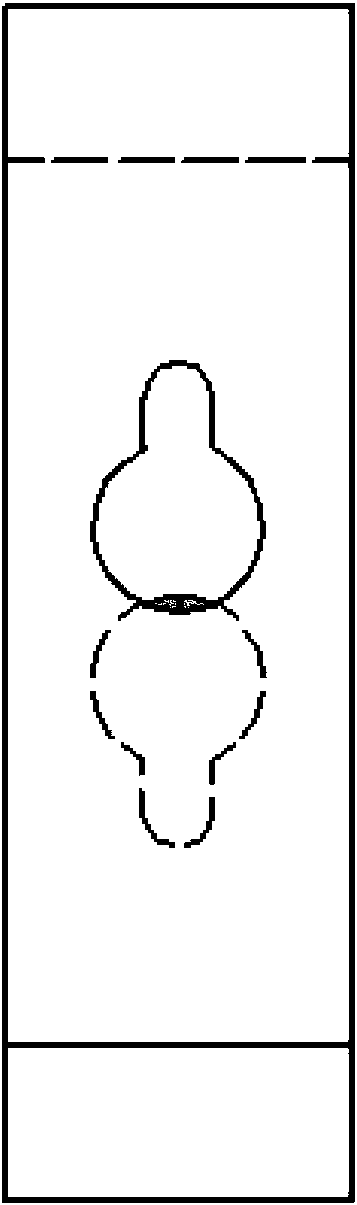

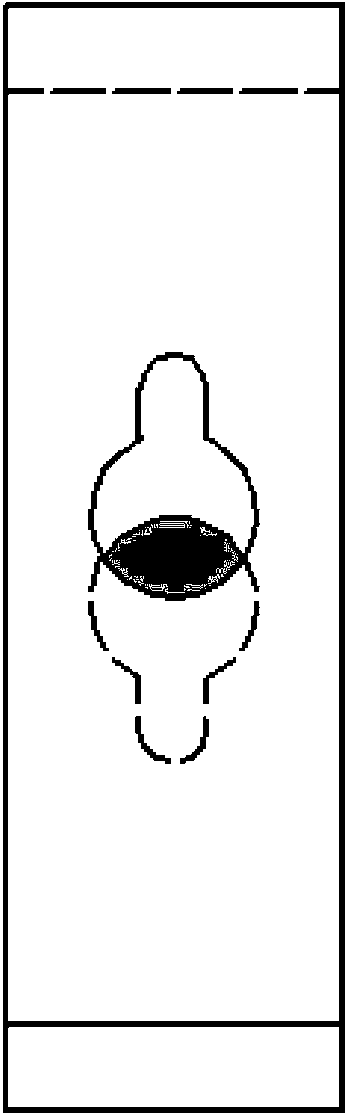

[0027] Change the opening shape of the slide valve brake air hole 4 and the slide valve seat hole 2 in the vehicle brake distribution valve, and the other structures of the distribution valve remain unchanged. The brake air hole 4 of the slide valve and the seat hole 2 of the slide valve are shaped like pear-shaped holes, and the two pear-shaped holes on the slide valve seat 1 and the slide valve 3 are set upside down. When the two largest pear-shaped circles coincide, the opening area of the brake cylinder charging hole is the largest. Before reaching the maximum opening area of the brake cylinder charging hole, the opening area of the brake cylinder charging hole moves up with the slide valve 3. The opening area gradually increases, and when the maximum area is reached, the opening area of the brake cylinder charging hole moves up with the spool valve 3, and the opening area of the brake cylinder charging hole gradually decreases, thereby changing the moving distanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com