Numerical control gantry milling machine of fixed beam

A technology of grinding machine and bed, applied in the field of fixed beam CNC gantry milling and grinding machine, can solve the problems of high labor intensity of workers and reduce work efficiency, and achieve the effect of improving processing efficiency and precision, improving utilization rate and wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

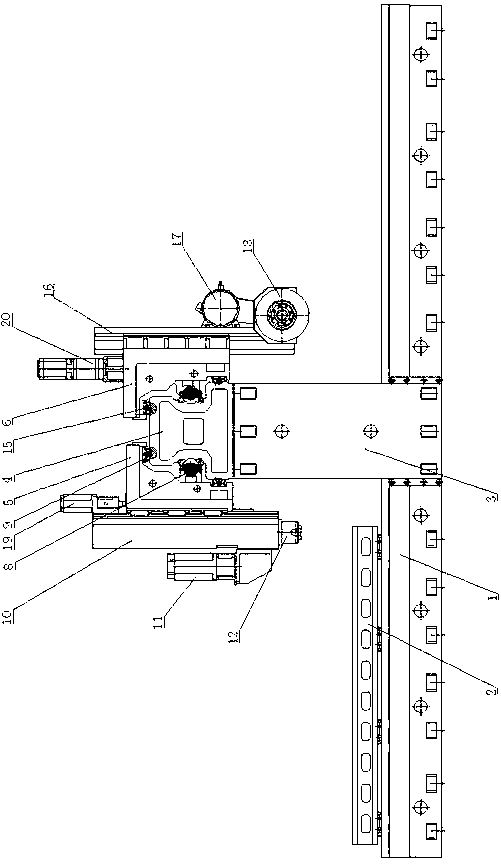

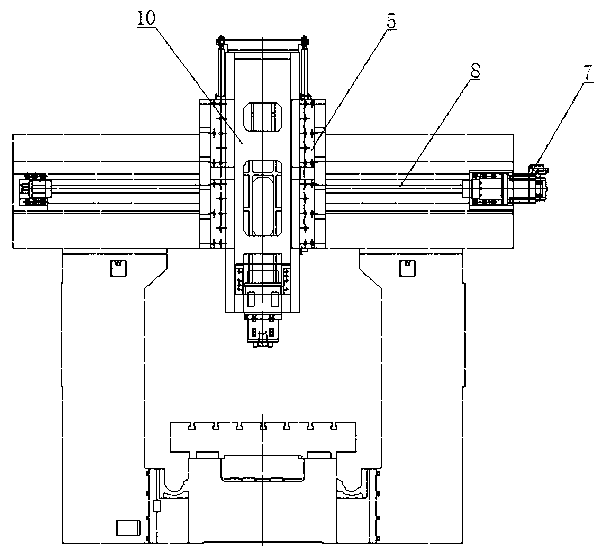

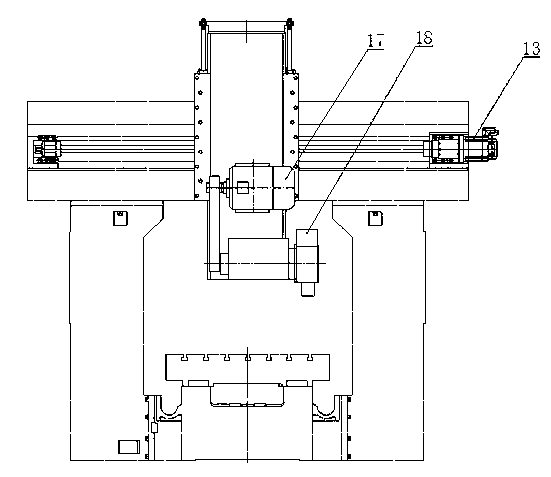

[0018] Such as figure 1 , 2 , 3, including bed 1, workbench 2, column 3, beam 4, milling slide 5, grinding slide 6, AC servo motor 7, ball screw nut pair 8, roller guide 9, milling slide Pillow 10, milling motor 11, milling spindle box 12, AC servo motor 13, ball screw nut pair 14, roller guide rail 15, grinding ram 16, grinding motor 17, grinding head 18, balancing device 19, balancing device 20.

[0019] The bed 1 is provided with a workbench 2 which can be arranged along the extending direction of the bed 1 , columns 3 are arranged on both sides of the bed 1 , and crossbeams 4 are connected at the tops of the two columns 3 . A milling slide 5 and a grinding slide 6 which can move along the horizontal direction of the crossbeam 4 are respectively arranged at the front and back of the crossbeam 4 .

[0020] The milling slide 5 drives the ball screw nut pair 8 through the AC servo motor 7 through the shaft coupling to move along the horizontal direction of the beam. The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com