Use method of portable ruling machine

A scribing machine and portable technology, applied in the field of steel plate raw material machining auxiliary equipment, can solve the problems of unfavorable popularization, lack of operational performance, high processing cost, etc., and achieve the effect of reducing operating cost, improving processing efficiency and precision, and being convenient to carry

Inactive Publication Date: 2013-06-12

NANJING HUIDE MACHINERY

View PDF0 Cites 5 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for large-scale plate (overweight, ultra-long) marking operations, it often does not have accurate and reliable operational performance due to the limitations of the use of measuring tools.

(Large numerical control equipment can complete the work, but the processing cost is too high, which is not conducive to popularization)

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

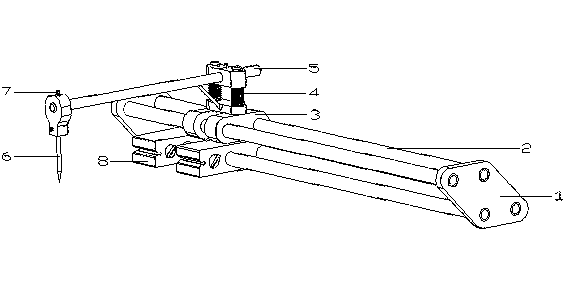

The invention relates to a use method of a portable ruling machine. The use method comprises the following steps that 1, sliding type adjustable powerful magnets (8) are pasted at the side surface of a plate, and the distance between the two sliding type adjustable powerful magnets (8) can be regulated according to the length of the plate; 2, after the installation in the proper position, the sliding type adjustable powerful magnets (8) are started through rotating a switch for adsorption; 3, then, a tungsten steel head part of a marking awl (6) is ground to be sharp and is arranged at the end part of a staff gauge (5), and in addition, a screw bolt (7) is fastened; 4, at the moment, the telescopic length of the staff gauge (5) can be regulated according to the dimension shown by a drawing; 5, two hands hold two ends of the staff gauge (5) to exert the force downwards so that the tungsten steel head part of the marking awl (6) is in contact with the surface of the plate, and meanwhile, a slide block (3) is pushed to slide on cylindrical slide rails (2); 6, after the two hands release, an elastic guide post (4) lifts the staff gauge (5) for reset, and the once ruling operation action is completed. The use method provided by the invention has the advantages that the processing efficiency and precision can be improved, the operation cost is reduced, the carrying is convenient, and the operation is carried out by one person.

Description

technical field The invention belongs to the field of auxiliary equipment for machining steel plate raw materials. Background technique At present, in the field of traditional machining (non-NC machining) manufacturing, in the drilling and tapping operations of ordinary plates, the dependence on personnel is still relatively large. Marking lines and dotting holes are indispensable preparatory work. For small boards, a height gauge can be used to perform more accurate marking operations. However, for large-scale plate (overweight, ultra-long) marking operations, it often does not have accurate and reliable operation performance due to the limitations of the use of measuring tools. (Large numerical control equipment can complete the work, but the processing cost is too high, which is not conducive to popularization). Contents of the invention The purpose of the present invention is to provide a portable marking machine that improves the efficiency and accuracy of marking...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B25H7/00B25H7/04

Inventor 刘圣祖唐立山

Owner NANJING HUIDE MACHINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com