Automatic device and method for preparing prior-alcohol-permeable composite membrane

A technology that preferentially penetrates alcohol and composite membranes. It is applied in the field of membrane separation. It can solve problems such as thick separation layers, surface defects, and unstable performance, and achieve the effects of thinner membrane surface thickness, simple technology, and rich materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] The support body is polysulfone (PS) material, flat ultrafiltration membrane, the pure water flux is 300LMH / bar, and the membrane area is 92cm 2 , the polymer material used is polydimethylsiloxane (PDMS, viscosity is 20000), the crosslinking agent is tetraethyl orthosilicate (TEOS, molecular weight is 208), the catalyst is dibutyltin dilaurate (molecular weight is 631), the solvents for polydimethylsiloxane, ethyl orthosilicate and dibutyltin dilaurate are n-heptane.

[0063] (1) Use n-heptane to make polydimethylsiloxane into 2000ml of 1wt% solution, stir and ultrasonically defoam to make polymer solution; use n-heptane to make orthosilicate into 1wt% % solution 2000ml, add 0.015% dibutyltin dilaurate, stir and ultrasonic defoaming to prepare crosslinking agent solution;

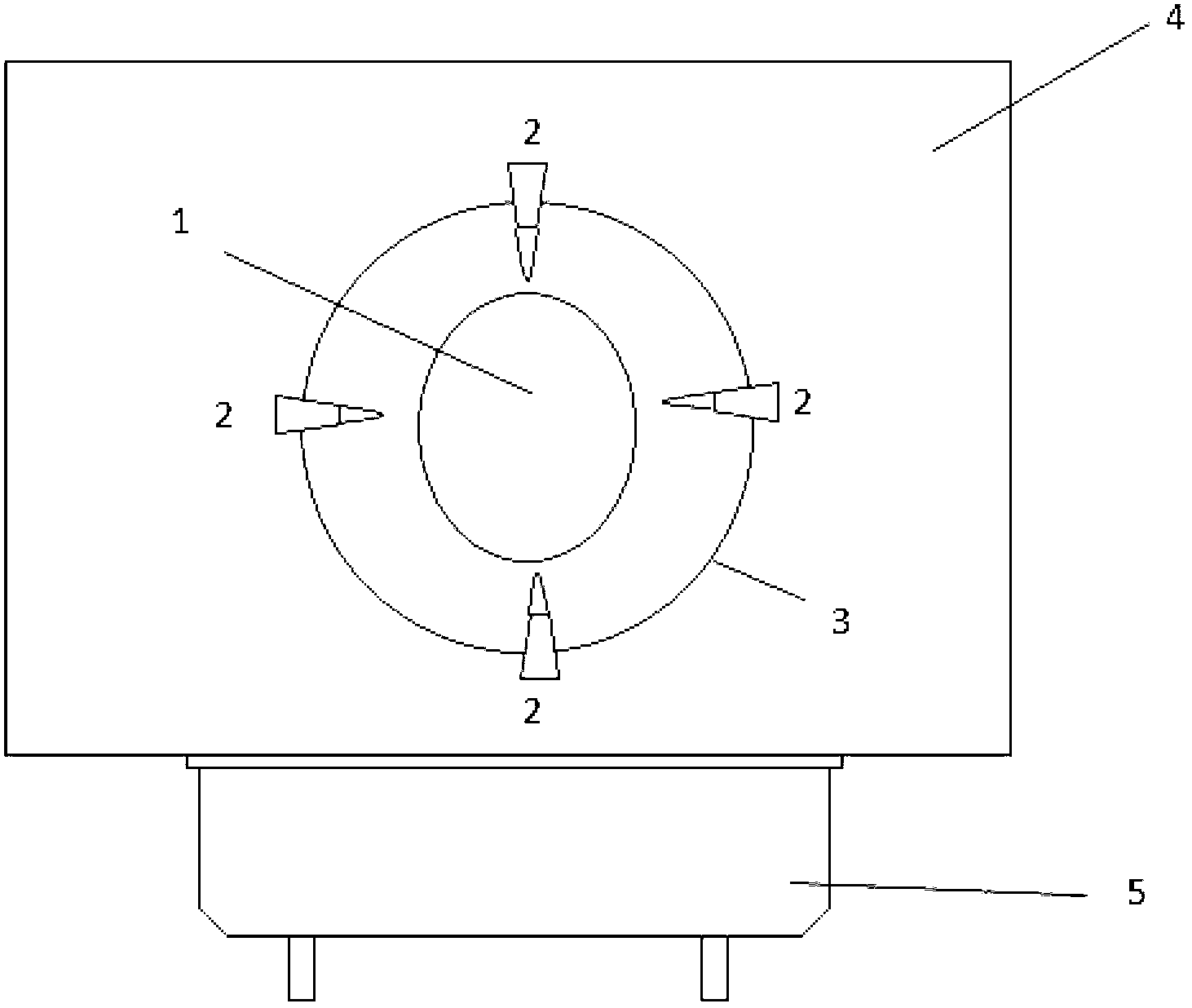

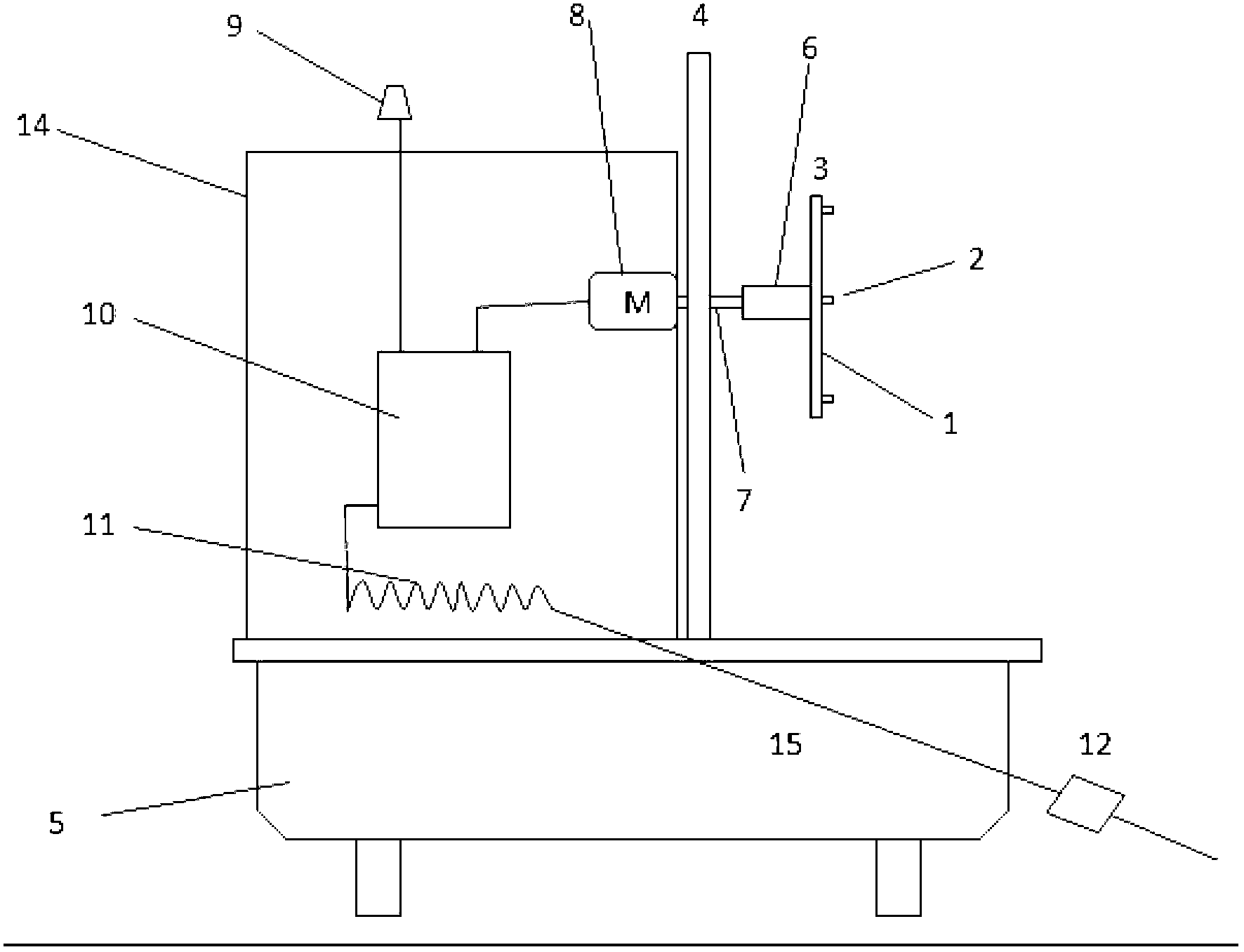

[0064] (2) Fix the polysulfone base film on the non-woven surface of the loading tray, and adjust the low-speed motor speed to 100rpm;

[0065] (3) Put the polydimethylsiloxane solution in the pres...

Embodiment 2

[0078] The support body is polysulfone (PS) material, flat ultrafiltration membrane, the pure water flux is 300LMH / bar, and the membrane area is 92cm 2 , the polymer material used is polydimethylsiloxane (PDMS, viscosity is 20000), the crosslinking agent is tetraethyl orthosilicate (TEOS, molecular weight is 208), the catalyst is dibutyltin dilaurate (molecular weight is 631), the solvents for polydimethylsiloxane, ethyl orthosilicate and dibutyltin dilaurate are n-heptane.

[0079] (1) Use n-heptane to make polydimethylsiloxane into a 5wt% solution of 2000ml, stir and ultrasonically defoam to make a polymer solution; use n-heptane to make tetraethyl orthosilicate into 1wt% % solution 2000ml, add 0.015% dibutyltin dilaurate, stir and ultrasonic defoaming to prepare crosslinking agent solution;

[0080] (2) Fix the polysulfone base film on the non-woven surface of the loading tray and adjust the low-speed motor speed to 100rpm;

[0081](3) Put the polydimethylsiloxane solutio...

Embodiment 3

[0093] The support body is polysulfone (PS) material, flat ultrafiltration membrane, the pure water flux is 300LMH / bar, and the membrane area is 92cm 2 , the polymer material used is polydimethylsiloxane (PDMS, viscosity is 20000), the crosslinking agent is tetraethyl orthosilicate (TEOS, molecular weight is 208), the catalyst is dibutyltin dilaurate (molecular weight is 631), the solvents for polydimethylsiloxane, ethyl orthosilicate and dibutyltin dilaurate are n-heptane.

[0094] (1) Use n-heptane to make polydimethylsiloxane into 2000ml of 1wt% solution, stir and ultrasonically defoam to make polymer solution; use n-heptane to make orthosilicate into 1wt% % solution 2000ml, add 0.015% dibutyltin dilaurate, stir and ultrasonic defoaming to prepare crosslinking agent solution;

[0095] (2) Fix the polysulfone base film on the non-woven surface of the loading tray and adjust the low-speed motor speed to 100rpm;

[0096] (3) Put the polydimethylsiloxane solution in the press...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

| Osmotic flux | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com