Method for preparing mosquito slow-release attractant

A technology of attractant and mosquito, applied in the direction of attracting pests, botanical equipment and methods, biocides, etc., can solve the problems of fast volatilization and short duration of effect, achieve good duration of effect, simple preparation method, good The effect of the lure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] This embodiment provides a kind of preparation method of new mosquito slow-release attractant, and its implementation steps are:

[0015] (1) Dissolve 7-10 parts by weight of 1-octen-3-ol, 2-5 parts by weight of heptyl acetate, and 6-9 parts by weight of nonylacetate in 100 volumes Parts of organic solvent for subsequent use;

[0016] (2) Stir 1000~7500 parts by weight of polyols with a molecular weight of <5000 at 40°C~75°C and a vacuum of -0.1Mpa for 60min;

[0017] (3) Add the spare solution in step (1) to the polyol in step (2), and continue stirring under the conditions of 40°C~75°C and a vacuum of -0.1Mpa until uniform, and then add 2500~10000 parts by weight isocyanate, continue to stir for 120min, and vacuumize after the stirring stops to obtain a paste-like mosquito slow-release attractant.

[0018] The applicant's experiment proves that the mosquito slow-release attractant has the characteristics of long-lasting effect, high efficiency, can reduce or avoid t...

Embodiment 1

[0023] Dissolve the attractant 1-octen-3-ol: 7g, heptyl acetate: 3g, methyl indole (nonylacetate): 6g in 100ml of acetone, set aside;

[0024] Stir 1kg of polybutadiene resin with a molecular weight of 3000 at 40°C and a vacuum of -0.1Mpa for 60min;

[0025] Add the acetone-dissolved solution to the stirred polybutadiene resin, continue to stir at 40°C and a vacuum of -0.1Mpa until uniform, then add 4.5kg of toluene diisocyanate, continue to stir for 120min, after the stirring stops Vacuumize to obtain a paste-like mosquito slow-release attractant;

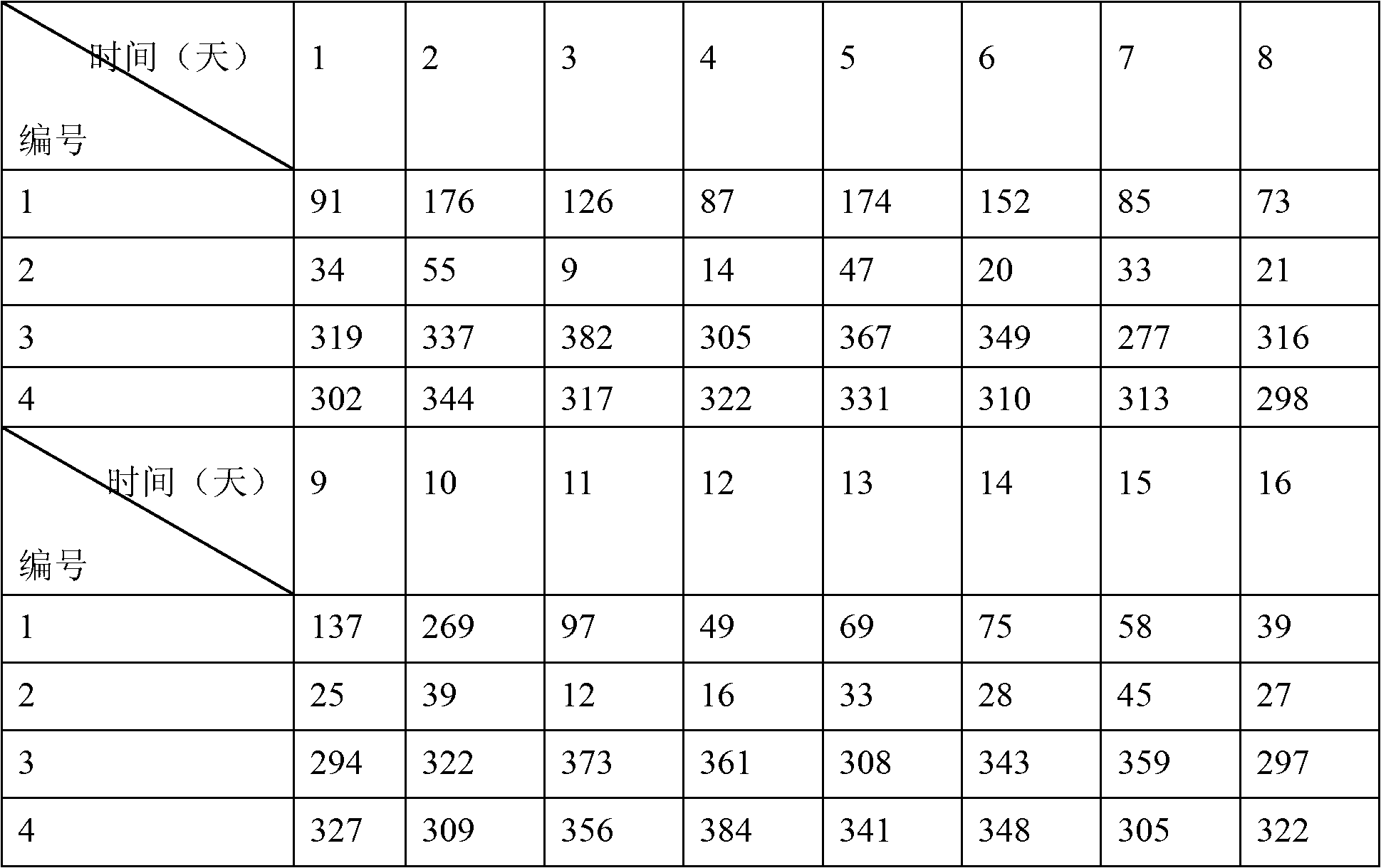

[0026] The creamy mosquito slow-release attractant is made into 5g / capsules according to the conventional capsule production method. The three attractant components (i.e., 1-octen-3-ol, heptyl acetate, and methyl indole (nonylacetate)) are all encapsulated in polyamethylene oxide formed by the reaction of polybutadiene resin and toluene diisocyanate. In the polymer film of ester. The capsule particles are filled into glass flas...

Embodiment 2

[0028] Dissolve the attractant 1-octen-3-ol: 10g, heptylacetate: 4g, methyl indole (nonylacetate): 8g in 100ml of acetone, and set aside;

[0029] Stir 1kg of hydroxyl-terminated polyether resin with a molecular weight of 2000 at 75°C for 60min at a vacuum of -0.1Mpa;

[0030] Add the solution dissolved in acetone above into the stirred hydroxyl-terminated polyether resin, and continue stirring at 40°C with a vacuum of -0.1Mpa until uniform, then add 5kg of cyclohexanediisocyanate at 75°C and a vacuum of -0.1Mpa Continue to stir for 120min at 0.1Mpa, vacuumize after the stirring is stopped, and obtain a paste-like mosquito slow-release attractant;

[0031] The paste mosquito slow-release attractant is made into 5g / capsule granules according to the conventional capsule production method. The three attractant components (i.e. 1-octen-3-ol, heptylacetate, and methyl indole (nonylacetate)) are all wrapped in polyamethylene oxide formed by the reaction of hydroxyl-terminated polye...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com