Method for preventing surface corrosion of flexible packaging lithium-ion battery

A lithium-ion battery and flexible packaging technology, which is applied to battery components, circuits, electrical components, etc., can solve the problems affecting the outer packaging of flexible packaging batteries, no effective treatment methods, battery leakage, etc., to save scrapped batteries and guarantee products The quality and the effect of preventing surface corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

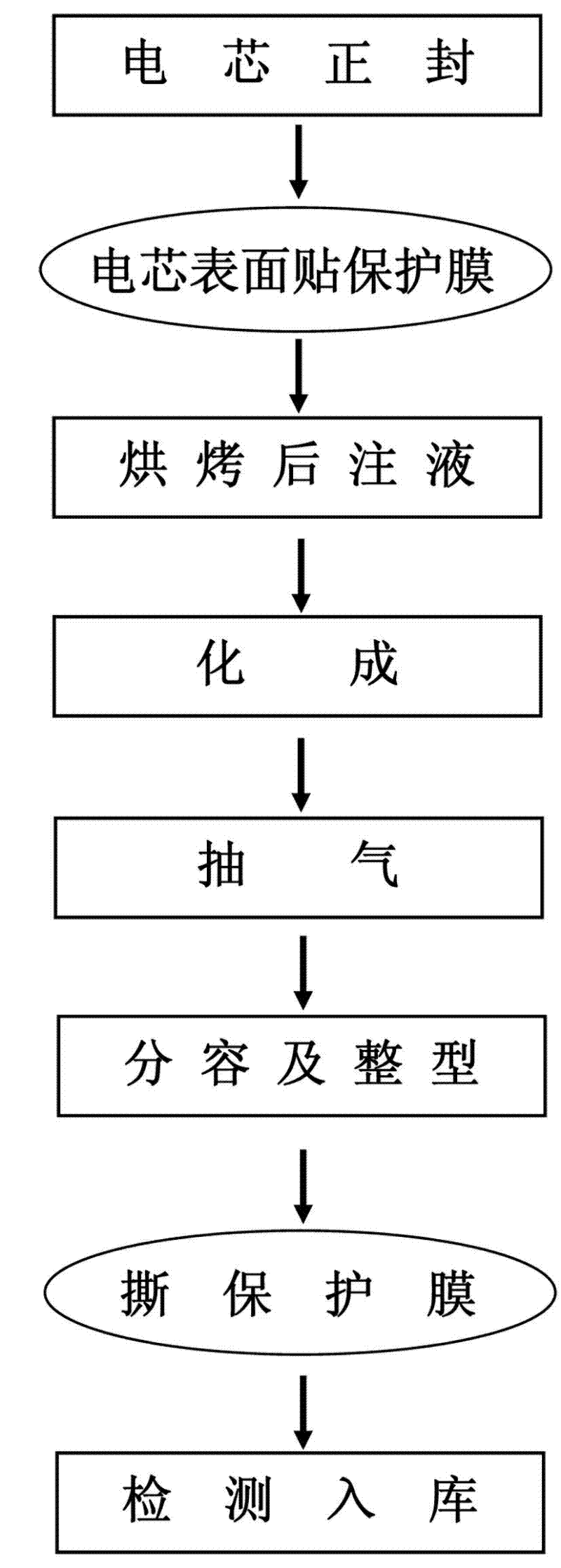

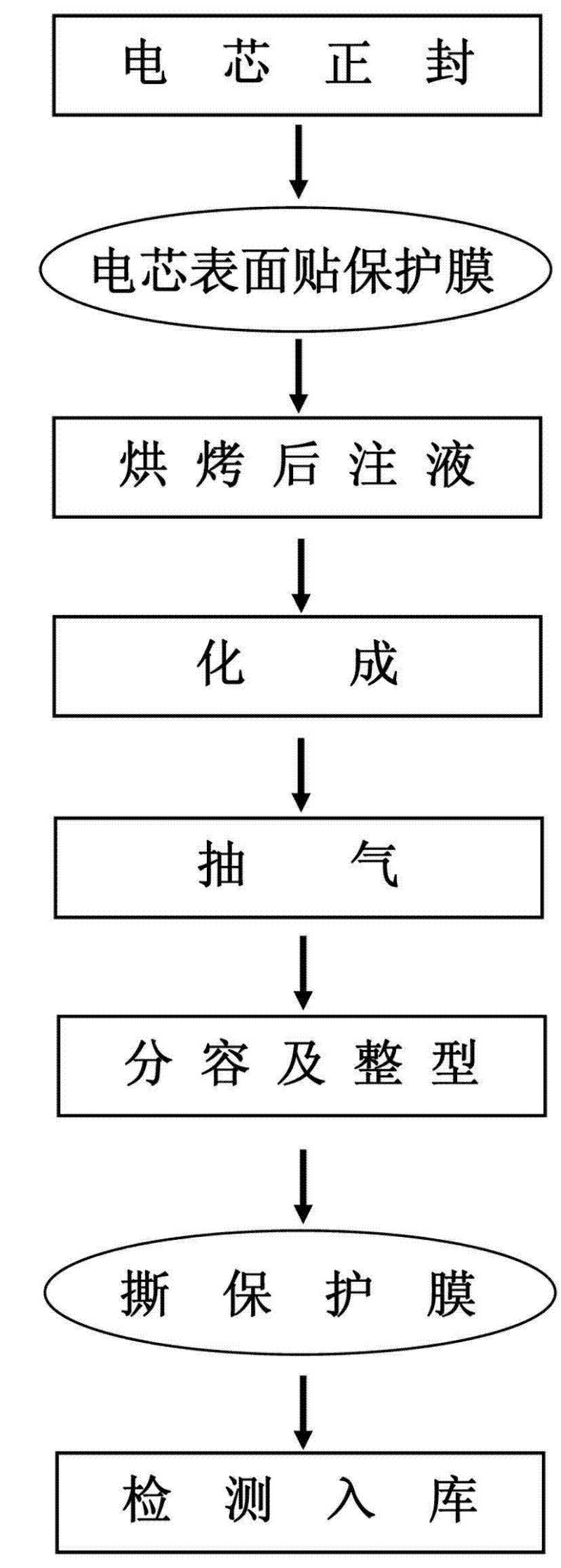

[0014] See figure 1 The production and assembly procedures of the existing soft-packaged lithium-ion battery are: battery core sealing, liquid injection after baking, formation, pumping, volumetric and shaping, and inspection and storage. The present invention is based on the above-mentioned prior art. The process of attaching a protective film and tearing the protective film on the surface of the cell is added, specifically: after the positive sealing process of the cell, a PE protective film is added on the surface of the cell, and the lithium ion battery with the protective film is still connected in sequence after baking The normal operating procedures of electrolyte injection, chemical formation, gas extraction, volume separation and shaping, the protective film removal procedure is added before the final inspection and storage of the soft-package lithium-ion battery.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com