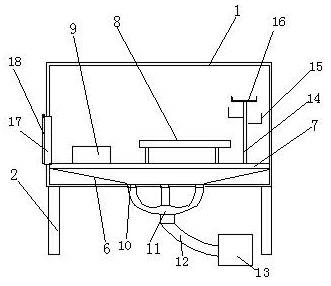

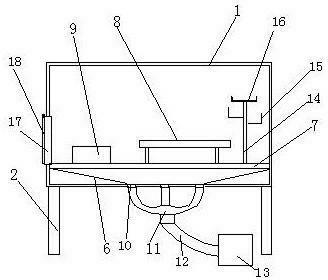

Operation box for filling ink powder into selenium drum

A technology for operating boxes and filling powder, which is applied in the fields of electrography, optics, instruments, etc., can solve the problem of toner overflow and achieve the effect of ensuring cleanliness and avoiding toner overflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Examples such as figure 1 , figure 2 As shown, a toner cartridge powder loading operation box includes a box body 1 provided with legs 2, the box body 1 is provided with a hinged observation area 3, and the box body 1 at the lower part of the observation area 3 A group of operation holes 4 are provided, and the dust-proof sleeve 5 is sleeved on the operation holes 4. It is characterized in that: the bottom of the box body 1 is provided with a bucket-shaped collection tank 6, and the collection tank 6 The upper part is provided with a mesh layer 7, and a tool placement rack, a workbench 8, and a finished product table 9 are arranged on the upper part of the mesh layer 7. The bottom of the box body 1 is also provided with 3 suction ports 10. The lower parts of the three dust suction ports 10 described above are connected to a multi-port connector 11, and the lower part of the multi-port connector 11 is connected to a dust suction device 13 provided with a pipeline 12. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com