Methods for manufacturing phase difference film and stereoscopic display device and phase difference film

A technology of a stereoscopic display device and a manufacturing method, applied in optics, instruments, nonlinear optics, etc., can solve the problems of complex manufacturing process and difficulty in effectively reducing manufacturing cost and man-hours, and achieve simplified manufacturing methods, reduced manufacturing costs and man-hours, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, but not as a limitation of the present invention.

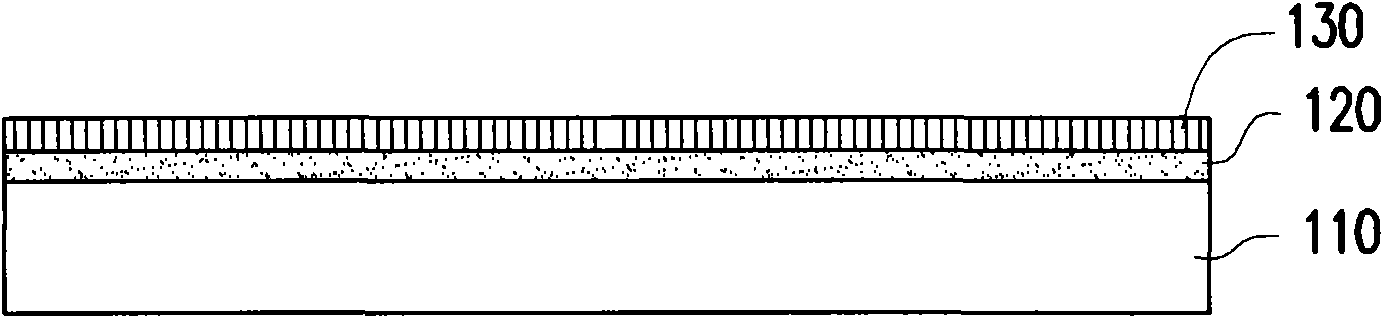

[0049] Figure 1A to Figure 1F It is a schematic flowchart of a method for manufacturing a retardation film according to an embodiment of the present invention. Please refer to Figure 1A to Figure 1F , The manufacturing method of the retardation film of this embodiment includes the following steps. First, if Figure 1A As shown, a transparent substrate 110 is provided. In this embodiment, the transparent substrate 110 is a transparent substrate, such as a glass substrate. However, in this embodiment, the transparent substrate 110 may also be a transparent substrate made of other materials.

[0050] Next, an alignment layer 120 is formed on the transparent substrate 110 . In this embodiment, the material of the alignment layer 120 is, for example, polyimide. Specifically, a layer of align...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com