Light flexible liquid stab-proof material and preparation method thereof

A soft, anti-stab technology, applied in protective equipment, offensive equipment, personnel protection equipment, etc., can solve the problems of high production cost, poor comfort, poor flexibility, etc., and achieve the effect of convenient operation, light weight, and good wearing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Configure the shear thickening liquid, the formula is as follows (weight ratio)

[0025] Nano Spherical Silica 55%

[0026] Polyethylene Glycol 45%

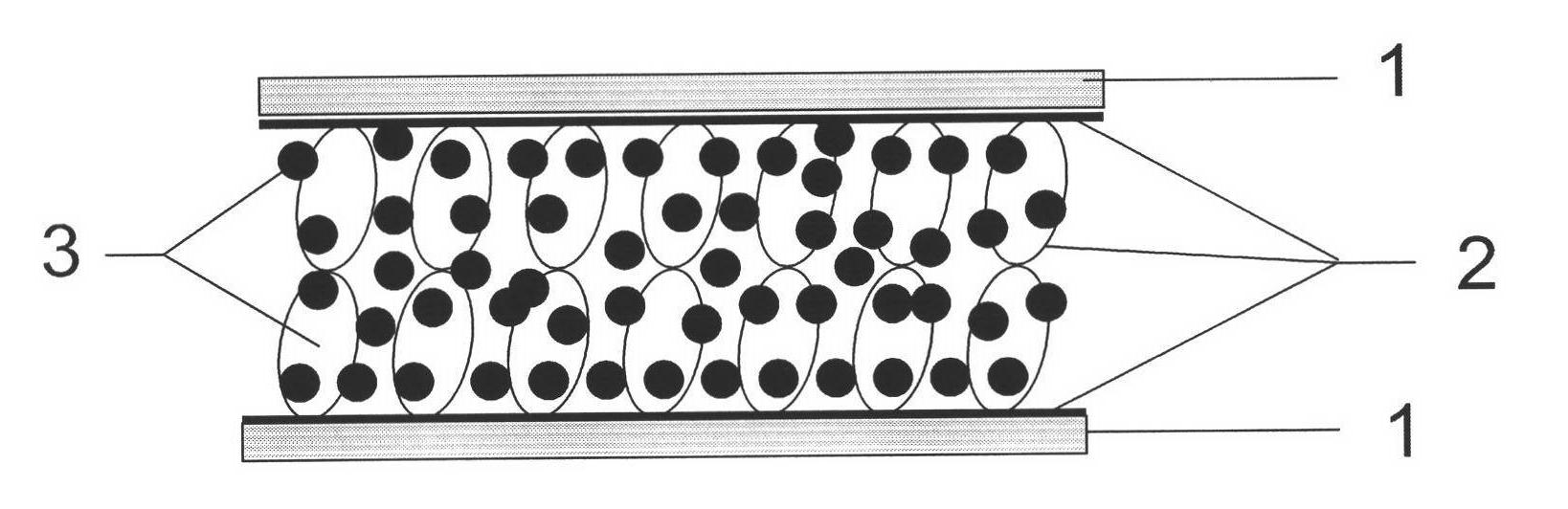

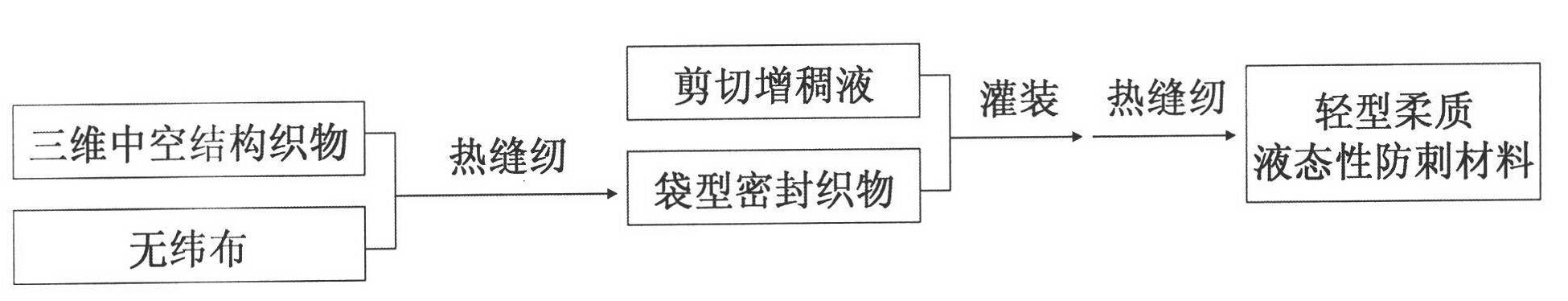

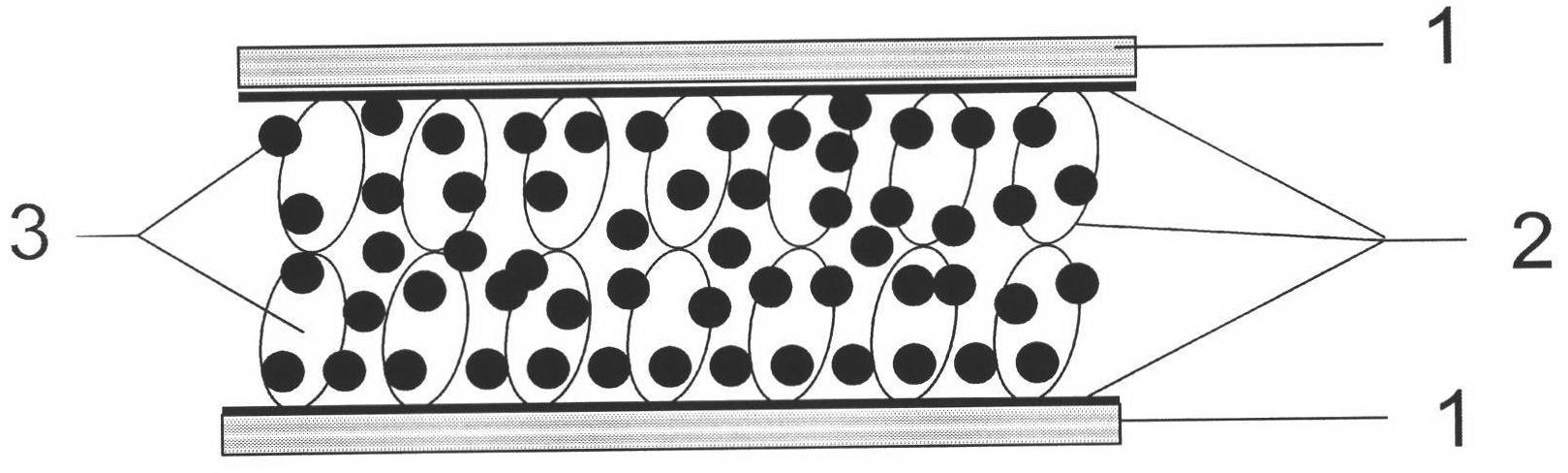

[0027] The non-weft fabric of high-strength ultra-high molecular weight polyethylene fiber and the three-dimensional hollow structure fabric of ultra-high molecular weight polyethylene are combined by hot sewing technology to make a leak-proof bag-type sealing fabric.

[0028] The prepared liquid with shear thickening properties is slowly filled in batches into the prepared ultra-high molecular weight polyethylene fiber bag-shaped sealing fabric in proportion to make a light and soft liquid stab-proof material. One of the formulations (volume ratio) is as follows:

[0029] Prepare the formula of lightweight flexible anti-stab material as follows (volume ratio)

[0030] Shear thickener 65%

[0031] Bag Sealing Fabric 35%

Embodiment 2

[0033] Configure the shear thickening liquid, the formula is as follows (weight ratio)

[0034] Nano Spherical Silica 65%

[0035] Polyethylene Glycol 35%

[0036] The non-weft fabric of high-strength aramid fiber and the three-dimensional hollow structure fabric of aramid fiber are combined by hot sewing technology to make a leak-proof bag-type sealing fabric.

[0037] The prepared liquid with shear thickening properties is slowly filled in batches into the prepared aramid fiber bag-shaped sealing fabric in proportion to prepare a light and soft liquid stab-resistant material. One of the formulations (volume ratio) is as follows:

[0038] Prepare the formula of lightweight flexible anti-stab material as follows (volume ratio)

[0039] Shear thickener 60%

[0040] Bag seal fabric 40%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com