Biomass fuel produced by using potato starch residue and wastewater and production method for biomass fuel

A potato starch residue, biomass energy technology, applied in waste fuel, fuel, gas fuel and other directions, can solve the problems affecting the sustainable development of the potato industry, waste of resources, environmental pollution, etc., to achieve accelerated fermentation speed, large gas production, The effect of high survival rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

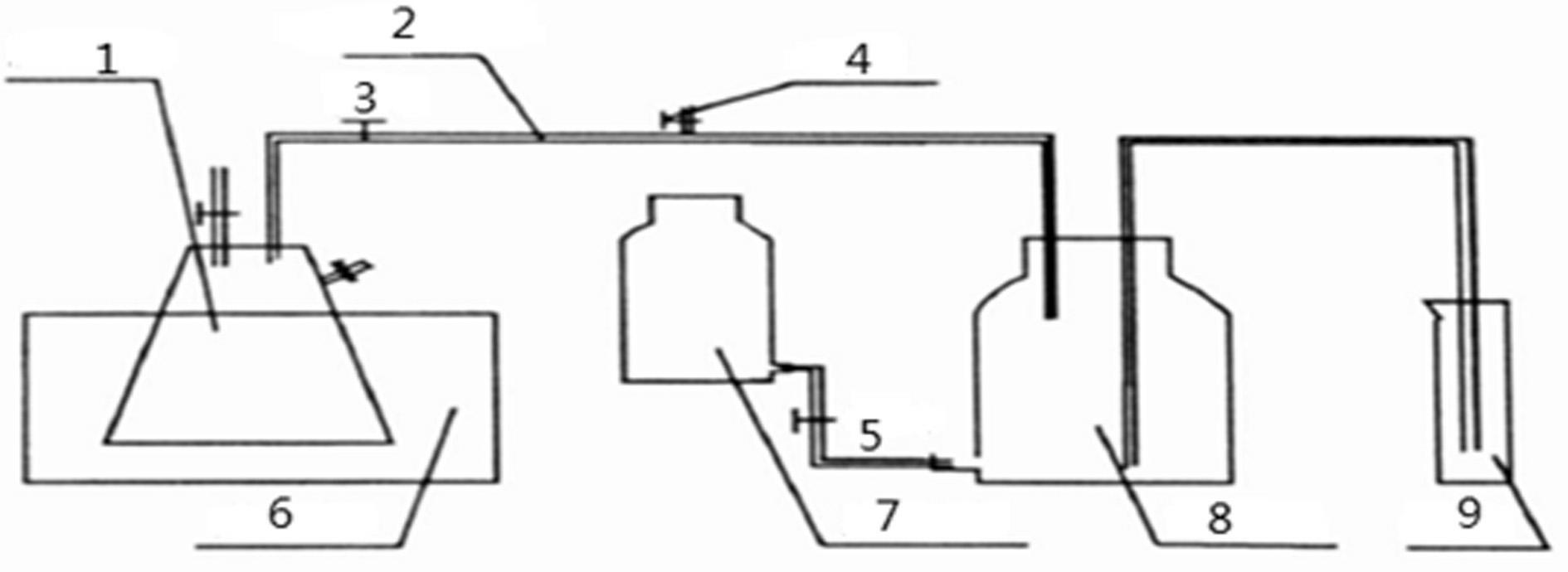

Image

Examples

Embodiment 1

[0040] Embodiment 1, utilize potato starch slag, the biomass fuel of waste water production, earlier potato slag, inoculum are allotted with described potato waste water and be 5% concentration in solid content, then it is mixed by 1:1, then by screw The pump is pumped into the reactor for anaerobic fermentation, and the fermentation temperature is maintained at 30 °C to produce biogas under the action of methanogenic bacteria. The biogas is desulfurized, decarbonized, purified, compressed, and stored in a gas storage tank. High-level calorific value of the product > 31.4MJ / m3, total sulfur (calculated as sulfur) ≤ 200mg / m3, hydrogen sulfide ≤ 15mg / m3, carbon dioxide ≤ 3.0%, oxygen ≤ 0.5%, meeting the "GB18047-2000 Compressed Natural Gas for Vehicles" standard , mainly used as vehicle gas (CNG), and can also be used as energy for household life.

Embodiment 2

[0041] Example 2, using potato starch slag and waste water to produce biomass fuel, the potato slag and inoculum were first prepared with the waste water to a concentration of 10%, then mixed at 1:1, and then pumped into the reactor by a screw pump Carry out anaerobic fermentation, keep the fermentation temperature at 35°C, and produce biogas under the action of methanogenic bacteria. The biogas is desulfurized, decarbonized, purified, compressed, and stored in a gas storage tank. High-level calorific value of the product > 31.4MJ / m3, total sulfur (calculated as sulfur) ≤ 200mg / m3, hydrogen sulfide ≤ 15mg / m3, carbon dioxide ≤ 3.0%, oxygen ≤ 0.5%, meeting the "GB18047-2000 Compressed Natural Gas for Vehicles" standard , mainly used as vehicle gas (CNG), and can also be used as energy for household life.

Embodiment 3

[0042] Example 3, using potato starch slag and waste water to produce biomass fuel, the potato slag and inoculum were prepared with the waste water to a concentration of 10%, then mixed at 1:1, and then pumped into the reactor by a screw pump Carry out anaerobic fermentation, keep the fermentation temperature at 56°C, and produce biogas under the action of methanogenic bacteria. The biogas is desulfurized, decarbonized, purified, compressed, and stored in a gas storage tank. High-level calorific value of the product > 31.4MJ / m3, total sulfur (calculated as sulfur) ≤ 200mg / m3, hydrogen sulfide ≤ 15mg / m3, carbon dioxide ≤ 3.0%, oxygen ≤ 0.5%, meeting the "GB18047-2000 Compressed Natural Gas for Vehicles" standard , mainly used as vehicle gas (CNG), and can also be used as energy for household life.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com