Culture medium and preparation method thereof, microbial material and application and preparation method thereof

A medium and microorganism technology, applied in the biological field, can solve problems such as impossible application in practical applications, and achieve the effects of improving fruit taste, high quality and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

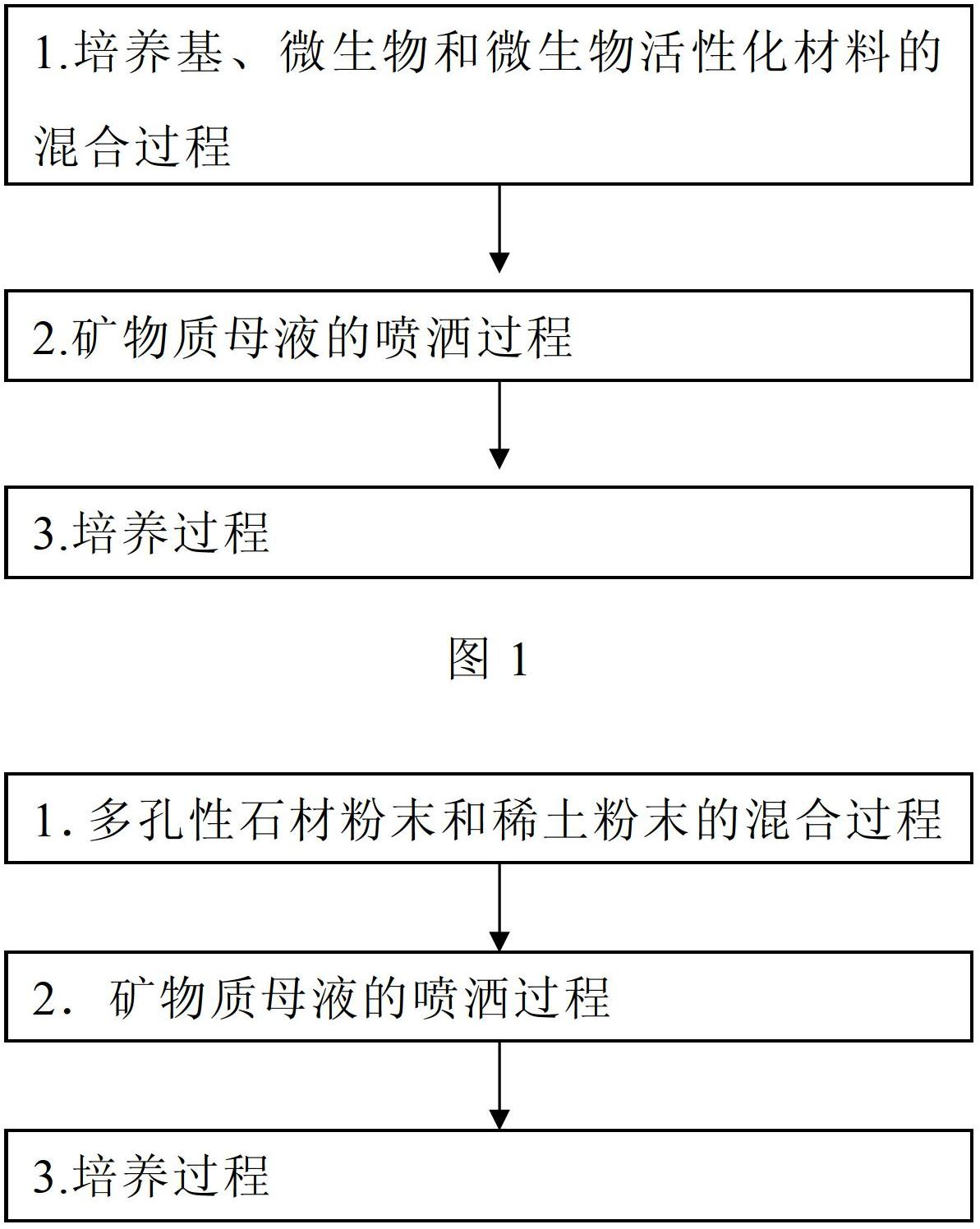

Image

Examples

preparation example Construction

[0049] The preparation process of the mineral mother liquor is described in detail below. The above-mentioned mineral mother liquors are made based on special mother liquors and minerals.

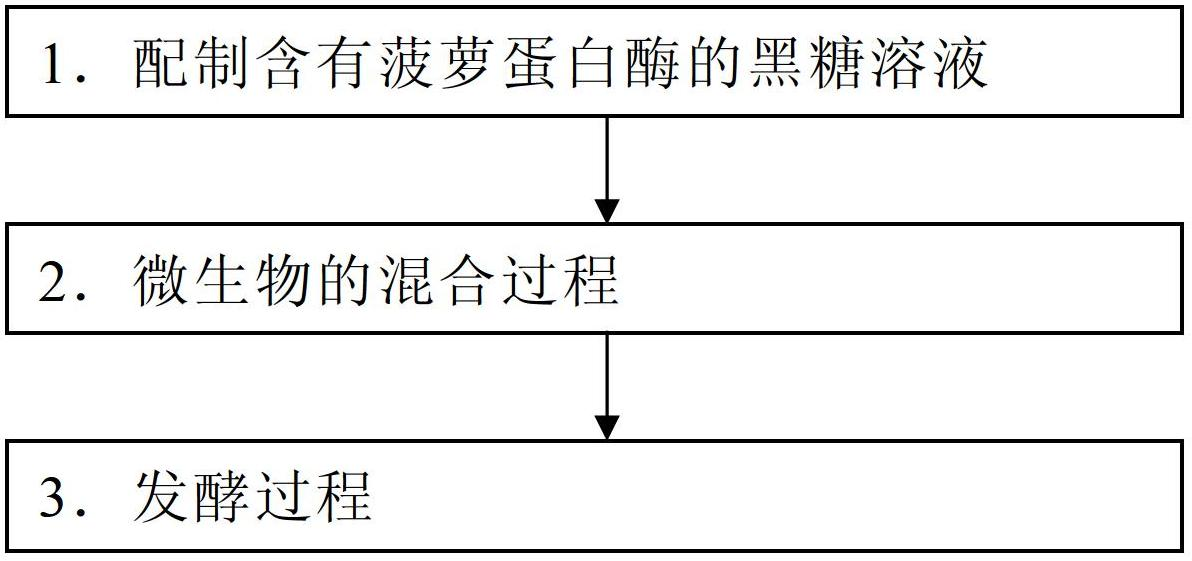

[0050] The preparation process of described special mother liquor sees image 3 .

[0051] The first step is to prepare a brown sugar solution containing bromelain: place bromelain in an aqueous brown sugar solution with a concentration of 7-15% by mass to obtain a brown sugar solution with a bromelain concentration of 60-100 U / mL;

[0052] The second step, the mixing process of microorganisms: in this process, the microorganisms of the genus Flavobacterium (Flavobacterium), microorganisms of the genus Pseudomonas, and Aspergillus are inoculated into the black sugar solution containing bromelain obtained in the first step. Microbes of the genus Aspergillus, microorganisms of the genus Rhizopus and bulgaric acid bacteria, wherein the weight ratio of the microbial liquid of the genus Flavob...

Embodiment 1

[0062] First, grind into 250-350 mesh chlorite powder (60 parts by weight), pegmatite powder (20 parts by weight), Duanhu silica powder (10 parts by weight), amphibole powder (9 parts by weight) and rare earth Powder (1 part by weight) was mixed. Then spray the above-mentioned mineral mother liquor (40 parts by weight) therein, heat and stir while spraying the above-mentioned mineral mother liquor, and mix uniformly. Then put it into a sealed container, and cultivate it at about 30° C. for 72 hours to obtain the culture medium of the present invention.

Embodiment 2

[0064] Grinding into 250~350 mesh chlorite powder (50 parts by weight), pegmatite powder (25 parts by weight), Duanhu silica powder (15 parts by weight), phyllite powder (8 parts by weight) and rare earth powder ( 2 parts by weight) mixed. Then spray the mineral mother liquor (35 parts by weight) therein, heat and stir while spraying the mineral mother liquor, and mix evenly. Then put it into a sealed container, and cultivate it at about 30° C. for 85 hours to obtain the culture medium of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com