Embossing type fast stamping process for surface of glass bottle

A glass bottle and embossing technology, which is applied in the field of medical equipment, can solve problems such as pollution, unfavorable energy saving and emission reduction, and operator injury, and achieve the effects of bright and firm color, improved bronzing efficiency, and improved curing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

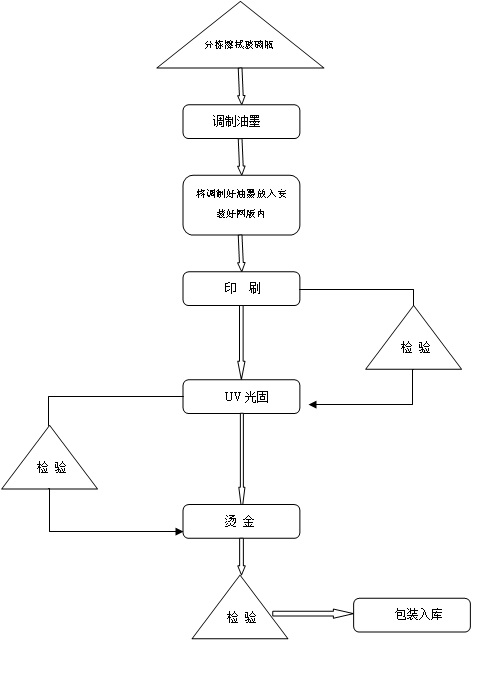

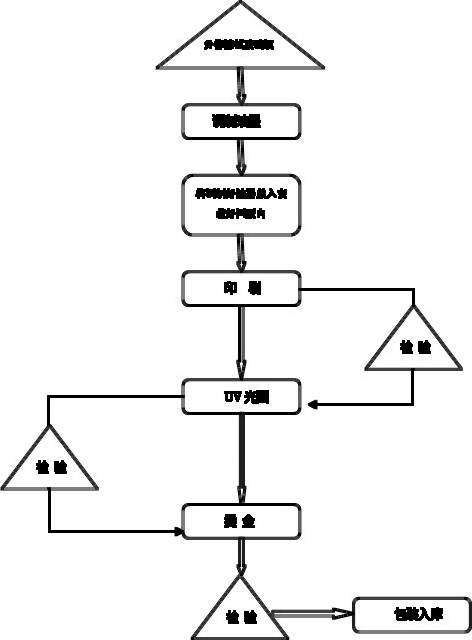

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0024] As shown in the figure, an embossed rapid hot stamping process on the surface of a glass bottle includes the following steps:

[0025] A. Glass bottles are sorted and wiped. After the glass bottles are unpacked, wipe the glass bottles evenly with a clean rag, and pick out the defective glass bottles, make a mark and place them separately;

[0026] B. modulation ink;

[0027] C. Put the prepared ink into the installed printing screen;

[0028] D. Carry out screen printing, put the glass bottle into the screen printing machine assembly line for ink printing, pick out the unqualified glass bottle, make a mark and place it separately;

[0029] E. UV light curing, put the glass bottle printed with ink into the UV light curing line and bake for 8 to 12 seconds;

[0030] F. Hot stamping, install hot stamping paper on the flat pressing hot stamping machine, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com