Method of processing and mass-producing green whole grains

A mass production and processing method technology, applied in the field of ), can solve the problems of high whole grain glutinous barley, lack of nutrition, poor taste in food, etc., and achieve the effect of overcoming seasonal restrictions, preventing adult diseases, and improving international competitiveness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

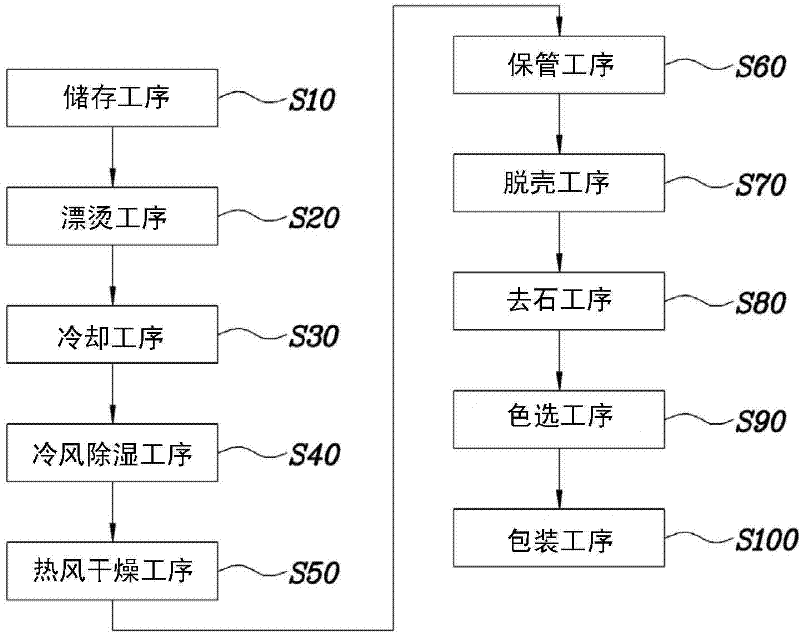

Method used

Image

Examples

Embodiment 1

[0048] On October 30 of the previous year (suitable sowing date), the new glutinous naked barley (Saechalssalbori) variety was sown on 1,200 pyeong in the plains of Gunsan District, Jeollabuk-do. May 20th (wax ripening period) confirmed the mature state of the caryopsis, judged that May 22nd (20th day after earing) was the most appropriate harvesting day, and harvested about Completed in 1 hour and a half. The weight of the green barley harvested at this time is 3,100 kg, which is relatively heavier than the average weight of 2,400 kg of barley harvested in the same area in the yellow ripening period, because the barley in the green state has more water content.

[0049] And, usually on the above-mentioned same area, it takes about 50 minutes to cut the barley in the yellow ripening period by the harvester, but it is not easy to cut the barley leaves, trunks, etc. of the barley in the green ripening state, so the cutting rotation speed ratio of the harvester is adjusted The r...

Embodiment 2

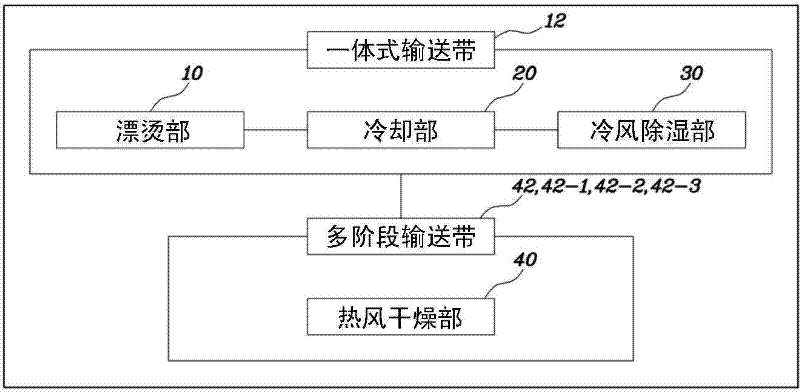

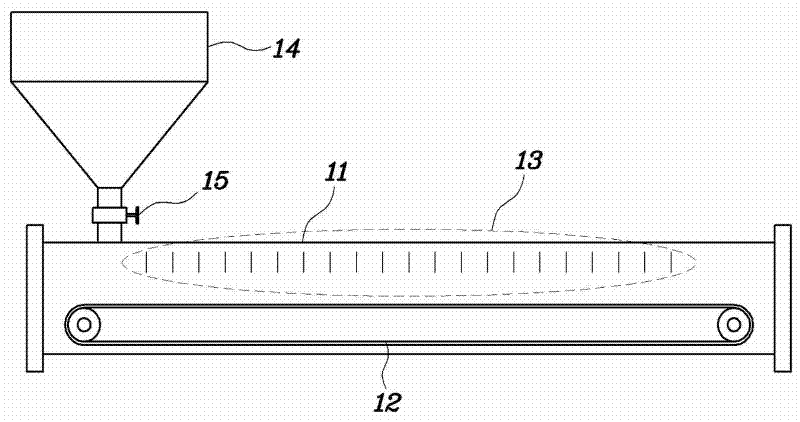

[0091] In Example 2, the blanching step S20, the cooling step S30, and the cold air dehumidification step S40 were implemented under the following conditions. For reference, in the blanching process S20, the cooling process S30, and the cold wind dehumidification process S40, the steel mesh conveyor belt used as a device for transferring green whole grains is composed of an integrated conveyor belt 12 that is continuously connected to each other, so that the above-mentioned processes are continuous. conduct.

[0092] 1. Processing objects (species): Hwanggeum-noeul, Hopum, Samgwang, Dongjin-chal, Boseok-chal, The green whole grain of Baekok-chal rice was used as the processing object.

[0093] 2. Blanching process: a steel mesh conveyor belt is used as the transfer device for the green whole grains, and the green whole grains are laminated on the conveyor belt with a thickness of 2.5 cm and passed through the steam channel 11 of 3.5 m. Also, steam at 100±1.5° C. was used t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com