Device for fusing hotmelt glue for products in the tobacco processing industry

A processing industry and hot glue technology, applied in the field of hot glue pellet melting devices, can solve the problems of hot glue overheating, hot glue not melting uniformly, cracking, etc., to achieve the effect of reducing cracking and shortening the start-up time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

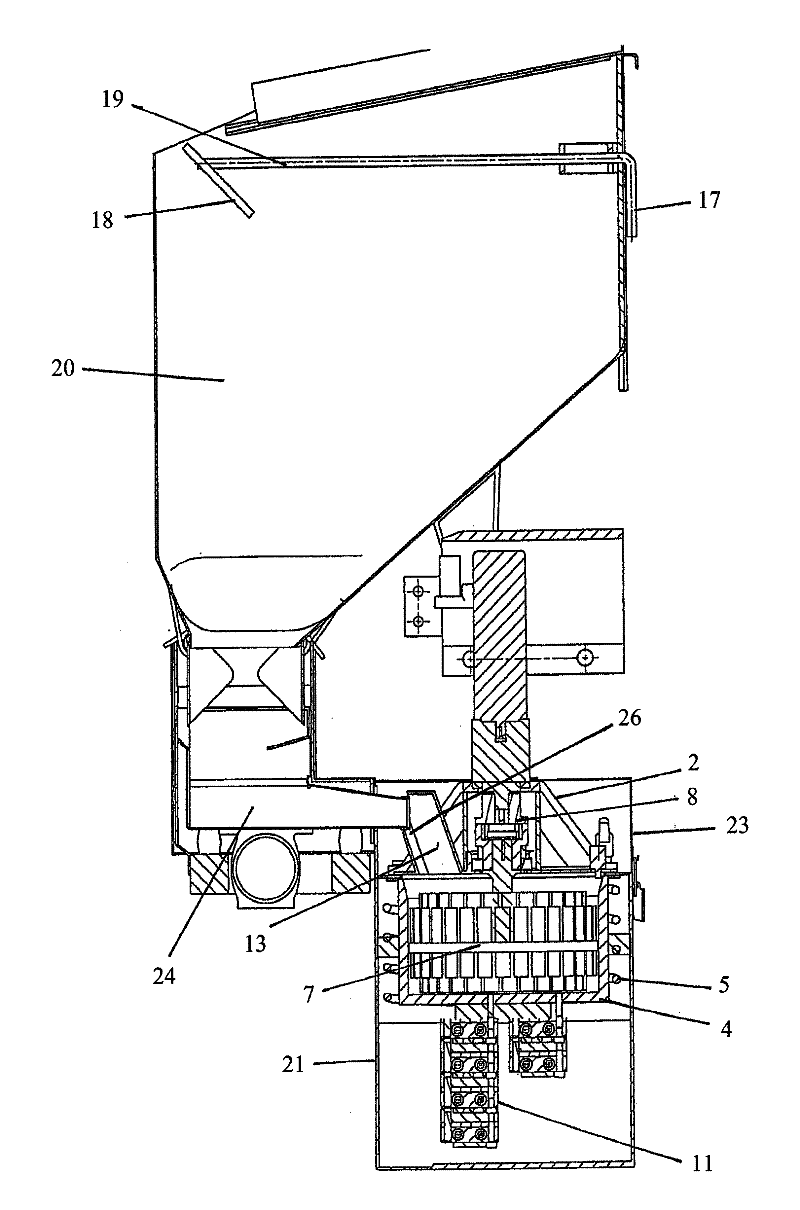

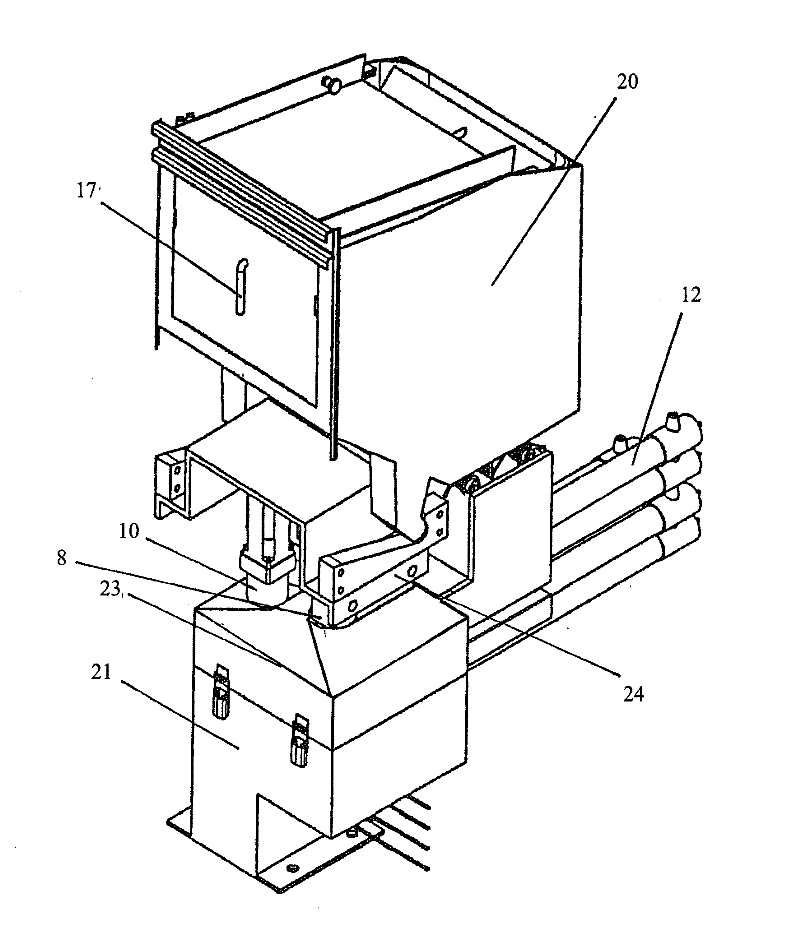

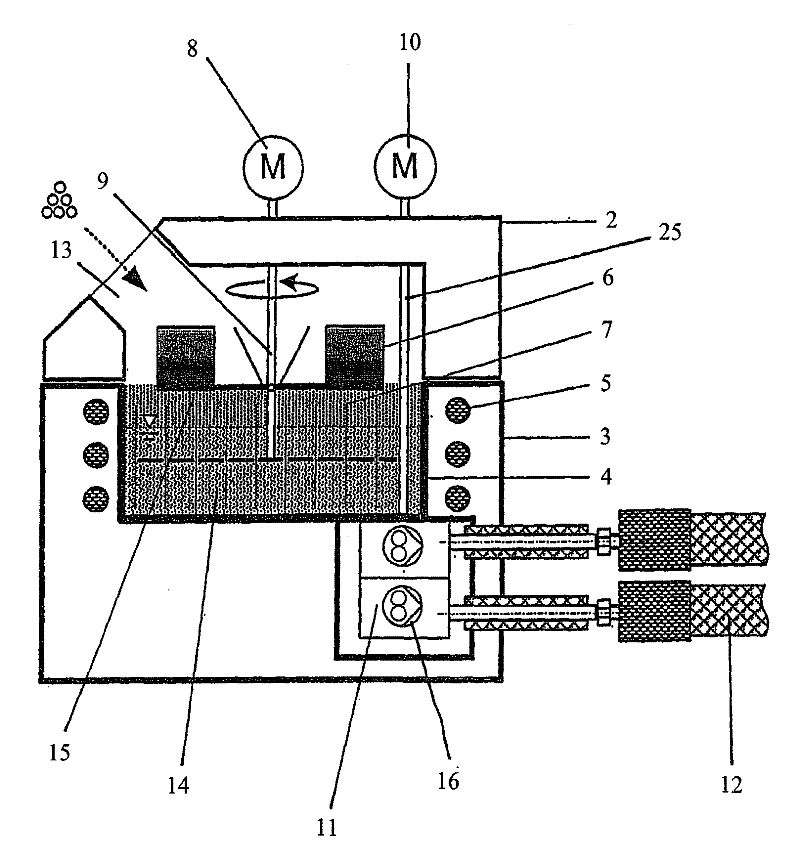

[0024] exist figure 1 with 2 The apparatus according to the invention for melting thermoglue granules for products of the tobacco processing industry, in particular for filters, into liquid thermoglue or also known as Hotmelt can be seen in isometric and sectional views, respectively. (hot melt adhesive). The device is a component of a superordinate plant in which the product is produced from raw materials in a continuous production process. The hot glue melted in this device is used, for example, to glue the edges of the filter paper and is applied in a thin film to one of the edges of the filter paper by means of a nozzle in an application device (not shown).

[0025] The device includes a storage container 20 configured in the form of a relatively large hot glue melting container with a volume of preferably 70 liters. In the storage container 20 is arranged a slider 17 that can be manipulated from the outside, the slider 17 has a pull rod 19 and a sliding plate 18, with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com