Roller tappet

A technology of rollers and shells, which is applied in a field, can solve the problem of high cost of roller tappets and achieve the effect of reducing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

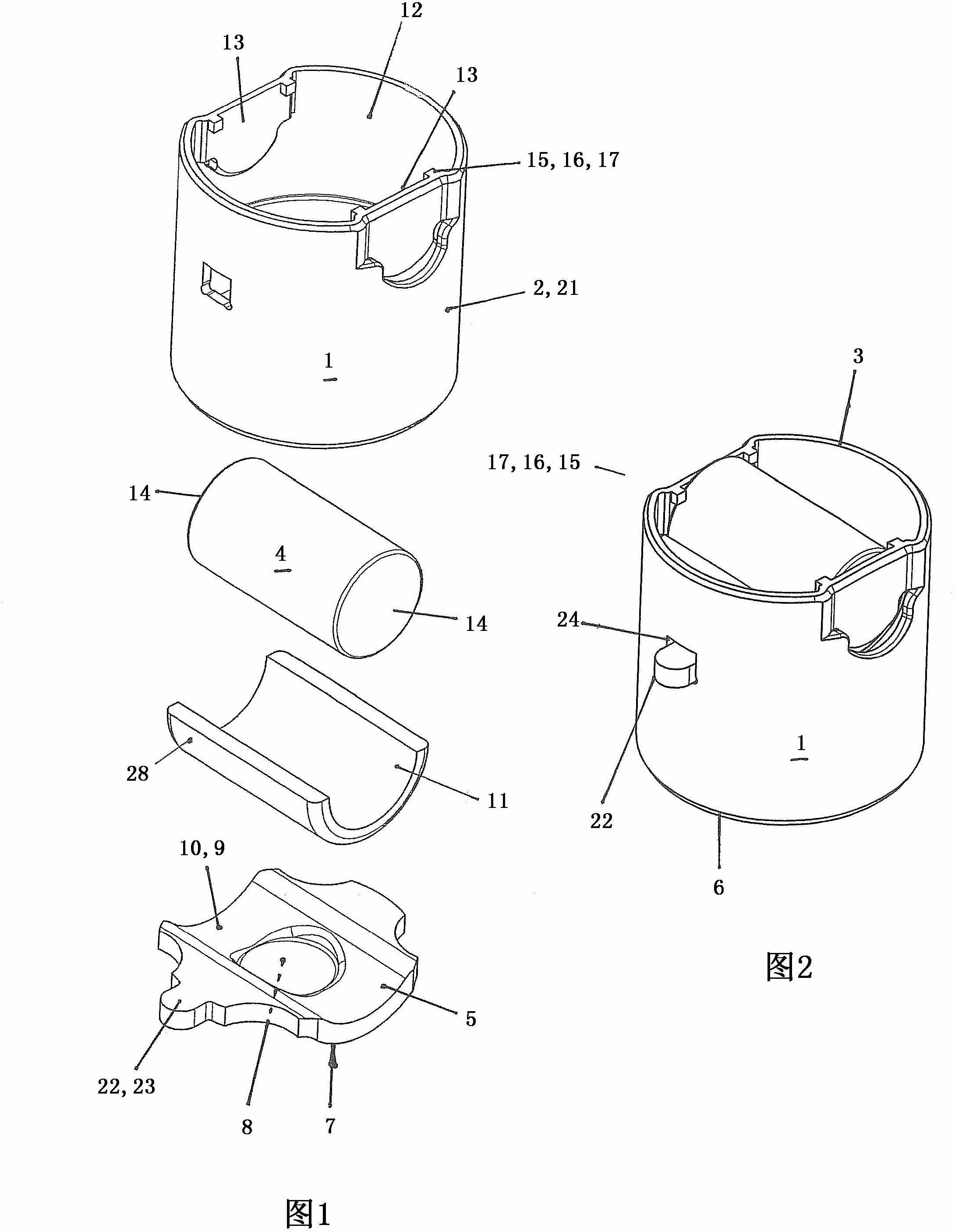

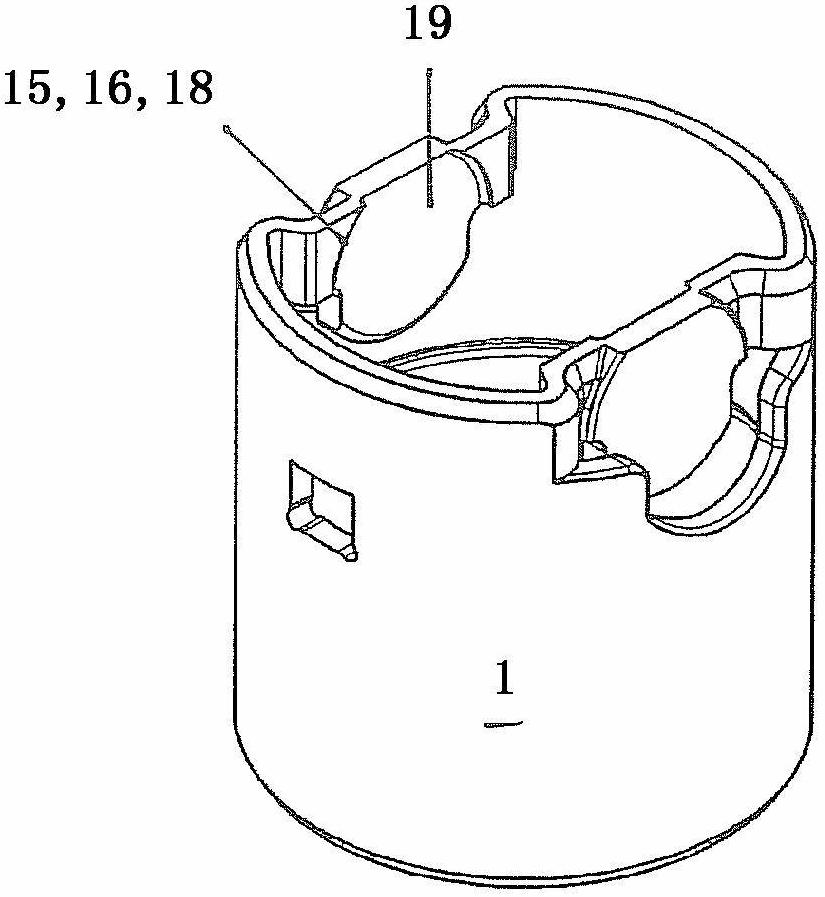

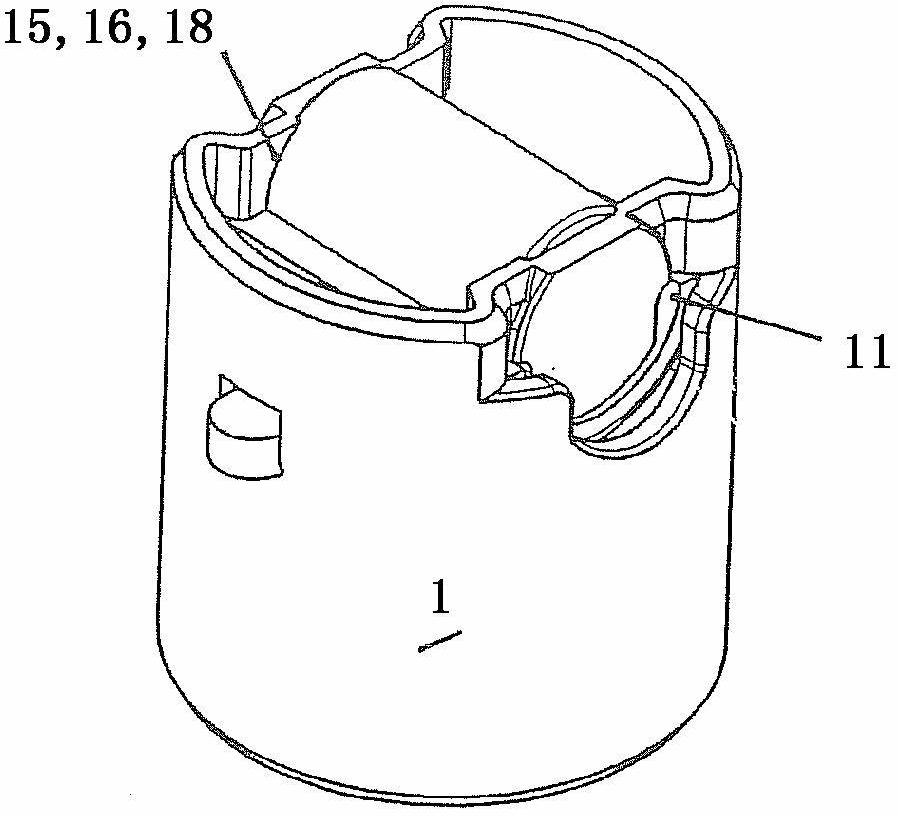

[0028] figure 1 A roller tappet 1 is disclosed, as in the case of its use as counter slide / counterpart for cams or eccentrics in high-pressure fuel pumps, for example for delivering diesel fuel. The roller tappet 1 has an approximately cylindrical housing 2 , via an outer wall 21 of which is guided in a recess of a high-pressure fuel pump or in a surrounding structure. In the region of the drive-side end 3 , the rollers 4 pass transversely through the housing 2 . According to Figure 1 to Figure 6 As a solution, the rollers 4 rest with their end faces 14 against the inner surface of the respective flat part 13 . The flat plate 13 is configured as a material depression.

[0029] The rollers 4 are slidably supported in a shell 11 which is separated from the roller rings as standard components. For example, splitting is conceivable as a separation process, so that each raceway can form two or three shell parts.

[0030] The shell part 11 is accommodated in a complementary mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com