LED (light-emitting diode) dot matrix display screen and combined dot matrix display screen

A display screen and LED chip technology, applied in the display screen field, can solve the problems of poor thermal conductivity, high temperature of LED chips and other devices, shortened service life, etc., and achieve the effects of good heat dissipation effect, good waterproof effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

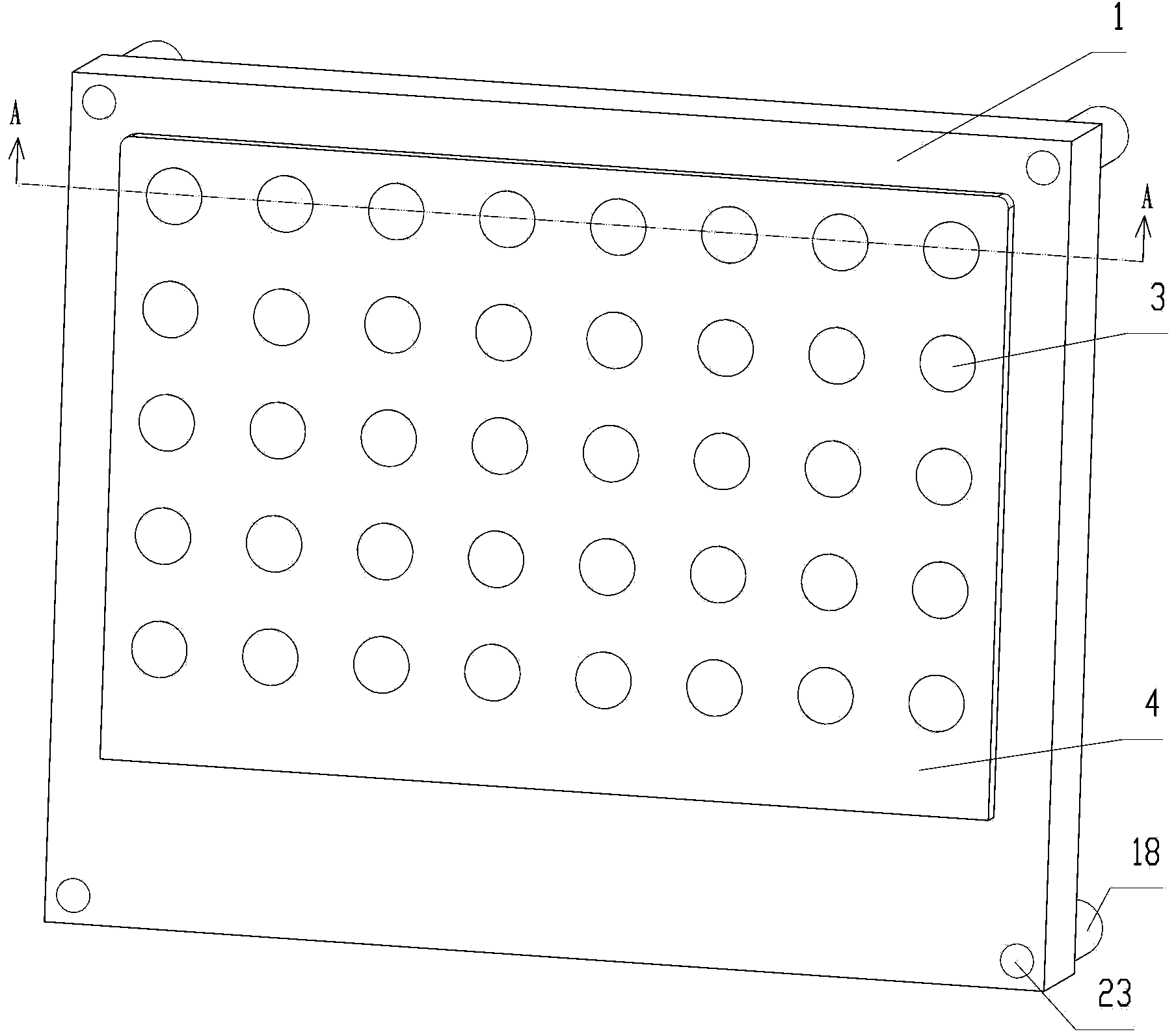

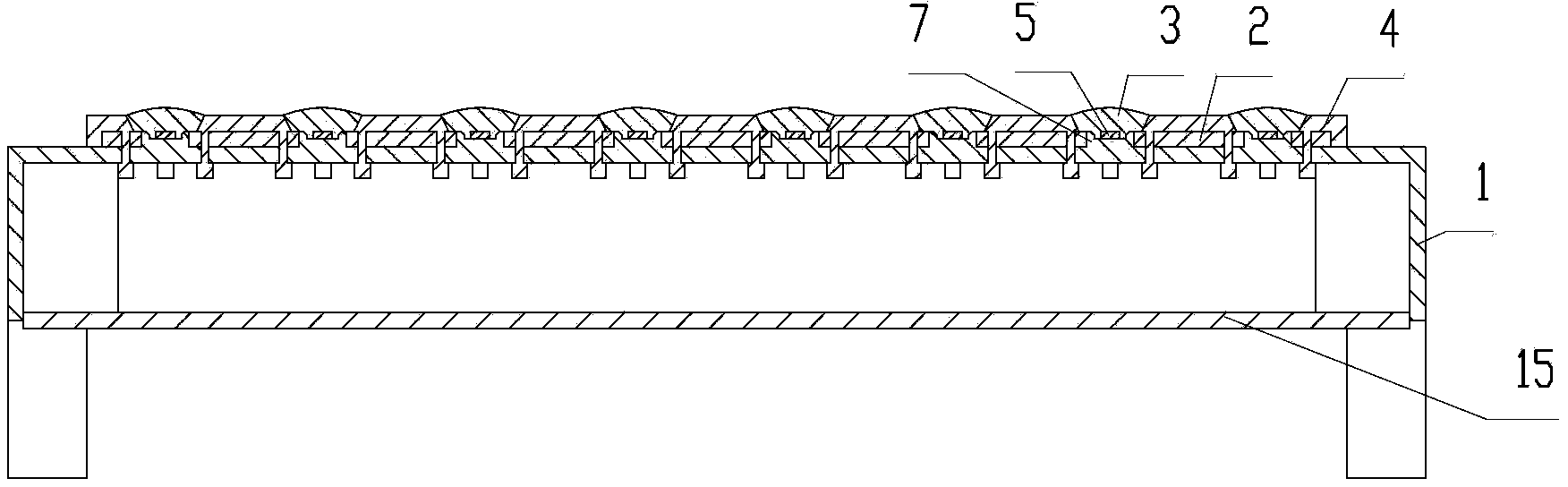

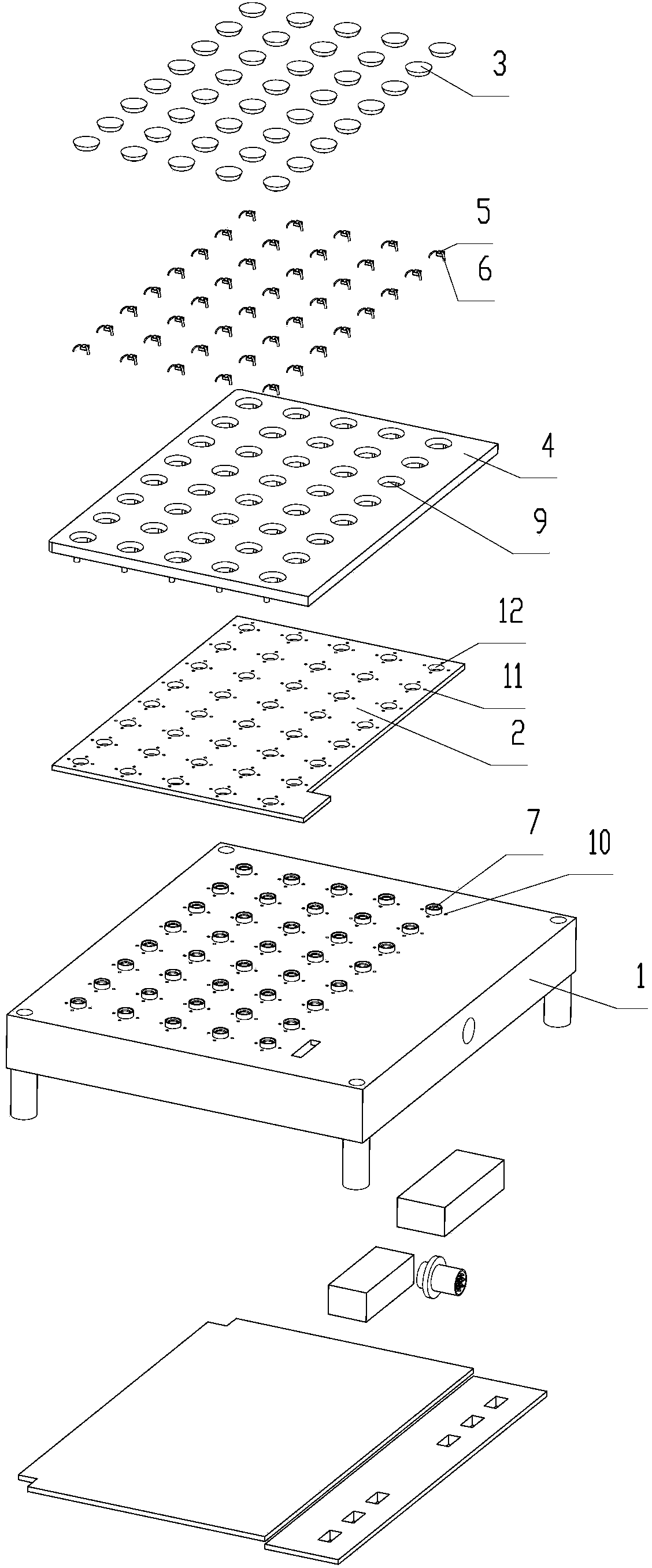

[0048] Such as Figure 1 to Figure 4 As shown, an LED dot matrix display screen includes a heat dissipation base 1, a PCB board 2, a light-transmitting encapsulation colloid 3 for packaging LED chips, a plastic plate 4 for forming and encapsulating the light-transmitting encapsulation colloid 3 for LED chips, and a uniform array of single primary colors LED light-emitting unit, imaging controller, layout circuit conductive layer (not shown); the layout circuit conductive layer is directly arranged on the PCB board 2, and the imaging controller is directly arranged on the back 2 of the PCB board away from the layout circuit conductive layer. face.

[0049] The LED light-emitting unit includes a single-color LED chip 5, a gold wire 6 electrically connected to the LED chip 5 and the conductive layer of the layout circuit, and a light-transmitting encapsulant 3 for encapsulating the LED chip 5; each LED chip 5 is passed through the layout. The conductive layer of the circuit is sep...

Embodiment 2

[0052] Such as Figure 5 to Figure 8 As shown, an LED dot-matrix display screen is different from Embodiment 1 in that a third heat dissipation through hole 52 penetrating through the plastic plate 51 is provided at the center of each of the four adjacent chip fixing bosses 50, penetrating through the The second heat dissipation through hole 54 of the PCB board 53, the first heat dissipation through hole 56 penetrating through the heat dissipation base 55, and the fourth heat dissipation through hole 58 penetrating through the runner cover plate 57, each chip fixing boss 50 is connected with the first heat dissipation through hole Holes 56 are adjacent. The imaging controller is directly arranged on the surface of the PCB 2 away from the conductive layer of the layout circuit. The uniform array of LED light emitting units has dual primary colors.

[0053] An outer wall 59 of the airtight chamber extends on the surface of the heat dissipation base 55 facing the PCB 53 , and a...

Embodiment 3

[0057] Such as Figure 9 As shown, the difference from Embodiment 2 is that a lateral heat dissipation fin 82 and a vertical heat dissipation fin 83 are provided on the side of the heat dissipation base 80 away from the PCB board 81 . The heat dissipation fins 82 are parallel to each other, and the heat dissipation fins 83 are parallel to each other. The gaps between the heat dissipation fins 82 and the heat dissipation fins 83 , the first heat dissipation through hole 84 , the second heat dissipation through hole 86 , and the third heat dissipation through hole 85 connected in series form a convective gas heat dissipation channel. The first heat dissipation through hole 84 runs through the heat dissipation fin 82 and the heat dissipation fin 83 , and the adjacent heat dissipation fins are not connected. The end of the first heat dissipation through hole 84 facing away from the PCB board 81 communicates with the outside air through the gap between the heat dissipation fins 82...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com