Fluid bed reactor and method of producing nitrile compound using same

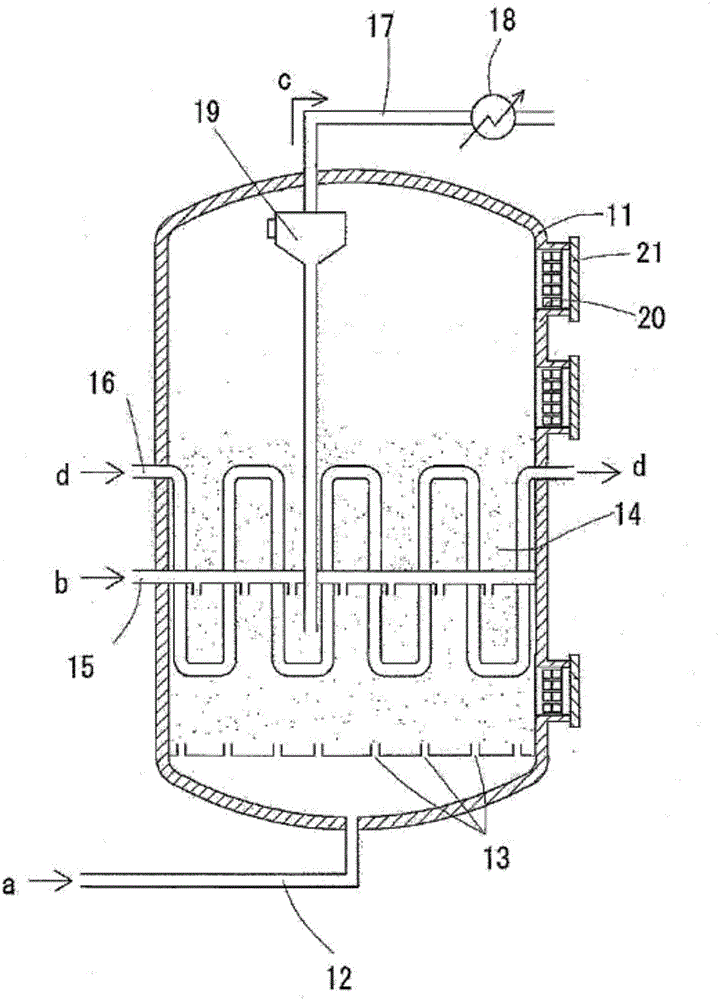

A fluidized bed reactor and reactor technology are applied in chemical instruments and methods, organic chemical methods, hydrocarbon ammonia oxidation preparation, etc., and can solve problems such as nozzle material corrosion, catalyst particle reduction and deterioration, and reactor material deterioration. The effect of preventing adverse effects, preventing material deterioration, and preventing high temperature heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

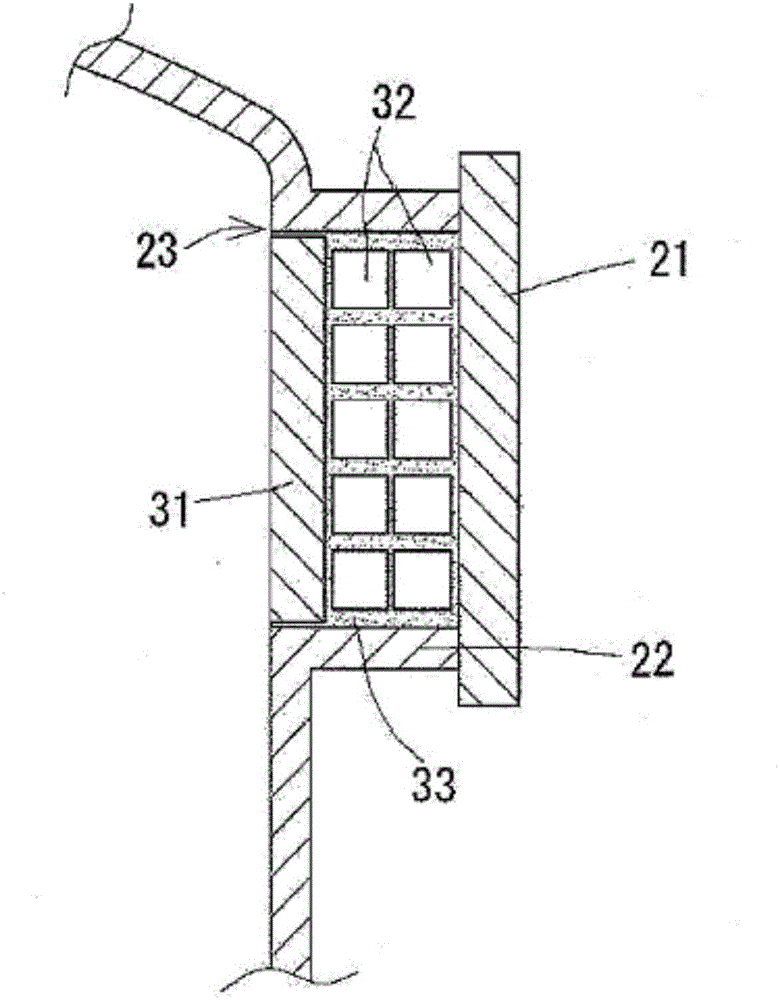

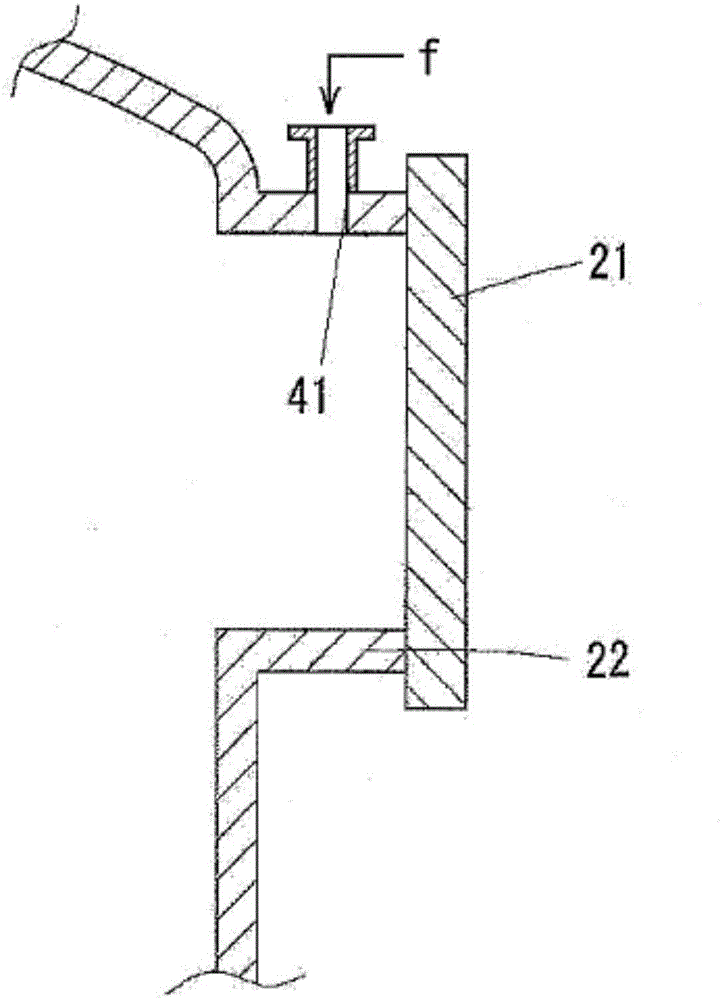

[0107] In a gas-phase oxidation fluidized bed reactor for the production of acrylonitrile by the ammoxidation reaction of propylene using a metal oxide catalyst containing molybdenum, the manhole installed on the wall surface made of SUS27 of the reactor main body is placed A SUS27 inner cover (diameter 900mm x depth 300mm) that is consistent with the inner diameter of the manhole is attached to the manhole from the inner wall side of the reactor so that there is no level difference between the periphery of the recess and the surface of the inner wall side of the inner cover. After the inside of the recess on the outside of the cover is covered with a calcium silicate heat insulating material (230mm x 110mm x 65mm brick shape), the entire remaining gap inside the manhole around the heat insulating material is filled with Portland cement to The surface of the periphery of the concave portion was dried so as not to have a difference in height, and then covered with an outer cover...

Embodiment 2

[0113] Except that the heat insulating material made of calcium silicate was replaced by refractory bricks, and Portland cement was replaced by refractory cement, the same operation as in Example 1 and the comparison before and after the operation were carried out, and the results were the same as in Example 1. , Compared with before the anti-deposition component was installed, after the anti-deposition component was installed, there was no catalyst accumulation, so no deterioration of the material was seen.

[0114] When the outer cover was opened after the operation stopped, the temperature around the manhole rose to 150°C before installing the anti-deposition member, but it did not reach a high temperature that hindered the work when it was opened after the anti-deposition member was installed.

Embodiment 3

[0116] Except that the SUS27 was replaced with the SUS304 which had been surface-treated by nickel plating, the same operation as in Example 1 and the comparison before and after the operation were carried out. Previously, after the anti-deposition parts were installed, there was no catalyst accumulation, so the deterioration of the material was not seen.

[0117] When the outer cover was opened after the operation stopped, the temperature around the manhole rose to 150°C before installing the anti-deposition member, but it did not reach a high temperature that hindered the work when it was opened after the anti-deposition member was installed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com