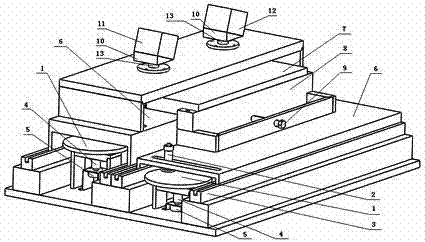

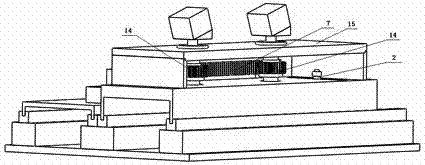

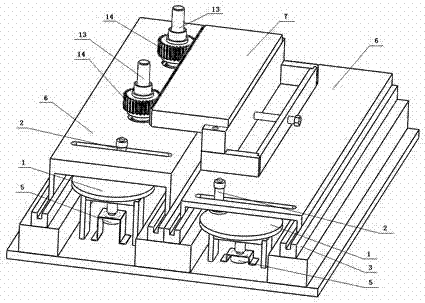

Calibration platform and calibration method for six-dimensional acceleration sensor

A technology of acceleration sensor and linear acceleration, applied in speed/acceleration/shock measurement, testing/calibration of speed/acceleration/shock measurement equipment, instruments, etc., can solve the problem of synchronous calibration of linear acceleration and angular acceleration, six-dimensional acceleration Inconsistency, lack of calibration information and other problems, to achieve the effect of multi-frequency acceleration excitation calibration, high calibration accuracy, and comprehensive calibration information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The motor 5 of the first linear drive mechanism and the motor 5 of the second linear drive mechanism are respectively at an angular velocity ω 1 , ω 2 The corresponding horizontal turntable 1 is driven to rotate at a constant speed, and the cylindrical pins on the horizontal turntable 1 move in the horizontal chute on the sliding platform 6, thereby pushing the sliding platform 6 to reciprocate along the guide rail. The linear displacement functions of the sliding platform 6 of the first linear drive mechanism and the sliding platform 6 of the second linear drive mechanism are respectively s 1 =r 1 cos(ω 1 t) and s 2 =r 2 cos(ω 2 t), where r 1 、r 2 Respectively represent the distance between the axis of the cylindrical pin and the axis of the corresponding horizontal turntable shaft projected on the plane of the horizontal turntable. The linear acceleration functions of the sliding platform 6 of the first linear drive mechanism and the sliding platform 6 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com