Improved detecting method for solid phase polypeptide synthesis by use of triketohydrindene hydrate

A solid-phase polypeptide synthesis and detection method technology, which is applied in the direction of analyzing materials through chemical reactions and material analysis through observing the impact on chemical indicators, etc., can solve the problem of roughly judging the completion of synthesis, the failure of synthesis reaction, and the like. Reduce the number of complete peptide chains, etc., to avoid false negative results, reduce health threats, and accurately determine the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] Implementation steps of the new ninhydrin method:

[0024] (1) Preparation of reaction reagents:

[0025] 1) Preparation of reduced ninhydrin: Weigh 500mg of ninhydrin, dissolve it in 12.5ml of boiling distilled water to obtain a yellow solution, dissolve 500mg of vitamin C in 25ml of warm distilled water, and add it to the ninhydrin solution, and a precipitate appears Then continue to stir for 15 minutes. After completion, move it to the refrigerator to cool to 4°C. After taking it out, the precipitate obtained by filtration is washed with water for 3 times. Store in a vacuum desiccator;

[0026] Buffer A: Mix 5ml pyridine + 1.185g phenol + 5ml ethanol;

[0027] Buffer B: 487.5mg ninhydrin + 12.5mg reduced ninhydrin + 10ml ethanol;

[0028] 25% piperidine solution: mix 25ml piperidine solution + 75ml nitrogen methyl pyrrolidone.

[0029] (2) Sample processing:

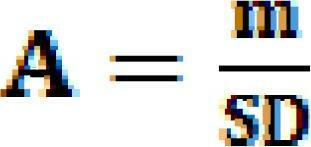

[0030] 1) Weigh 2g of Rink_Amide_MBHA resin, and calculate the required resin mole number A according t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com