Biomass burning machine of rotary furnace bridge

A biomass and rotary furnace technology, applied in the field of burners, can solve problems such as uneven distribution, insufficient combustion of biomass fuel, and hindering the combustion performance of biomass burners, so as to achieve sufficient combustion, improve combustion efficiency, and save social resources Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

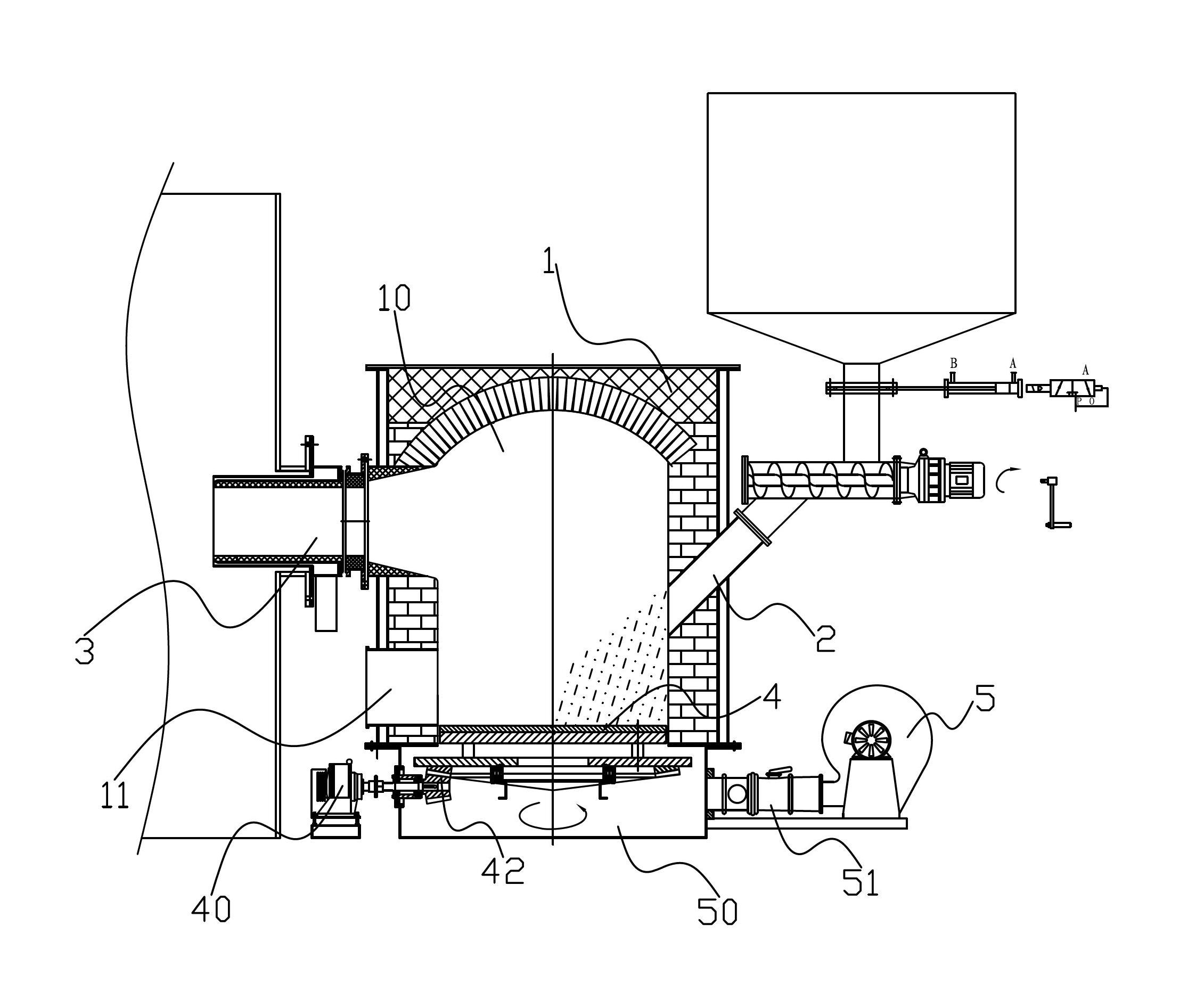

[0015] refer to figure 1 As shown in Fig. 3, a biomass burner with a rotary furnace bridge, first processes the main body 1 containing the combustion inner cavity 10, and then processes the hinge dragon 2 connected with the combustion inner cavity 10 on the right side wall of the main body 1, At the same time, a nozzle 3 connected to the combustion chamber 10 is installed on the upper part of the other side wall of the main body 1, and an outlet 11 communicating with the combustion chamber 10 is processed at the lower part of the main body side where the nozzle 3 is located. , and a valve that can open and close the ignition port 11 is installed at the ignition port 11. The above-mentioned hinge dragon 2 is preferentially set to become 45° obliquely downward with the main body 1, and of course it can be set to other angles.

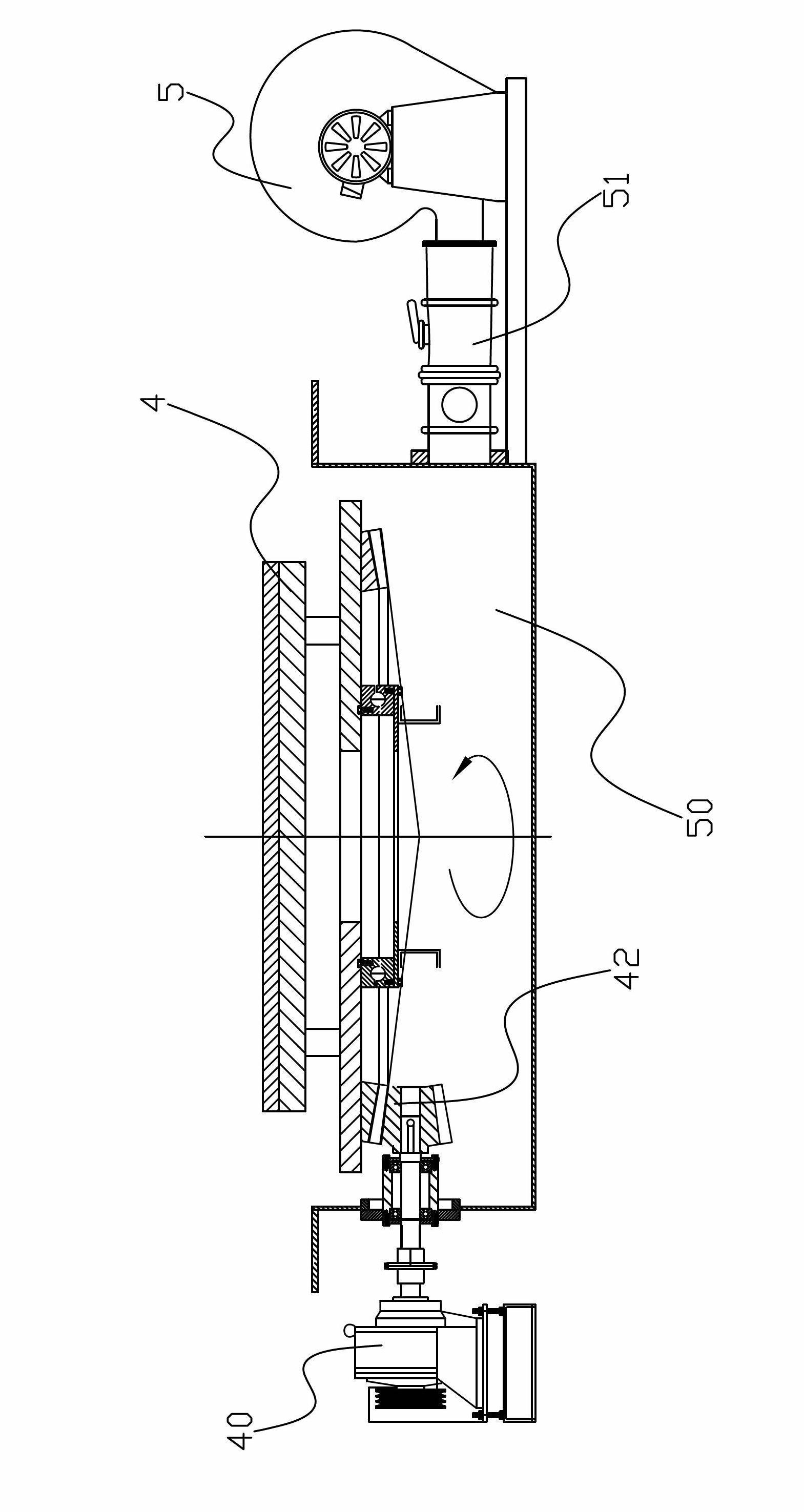

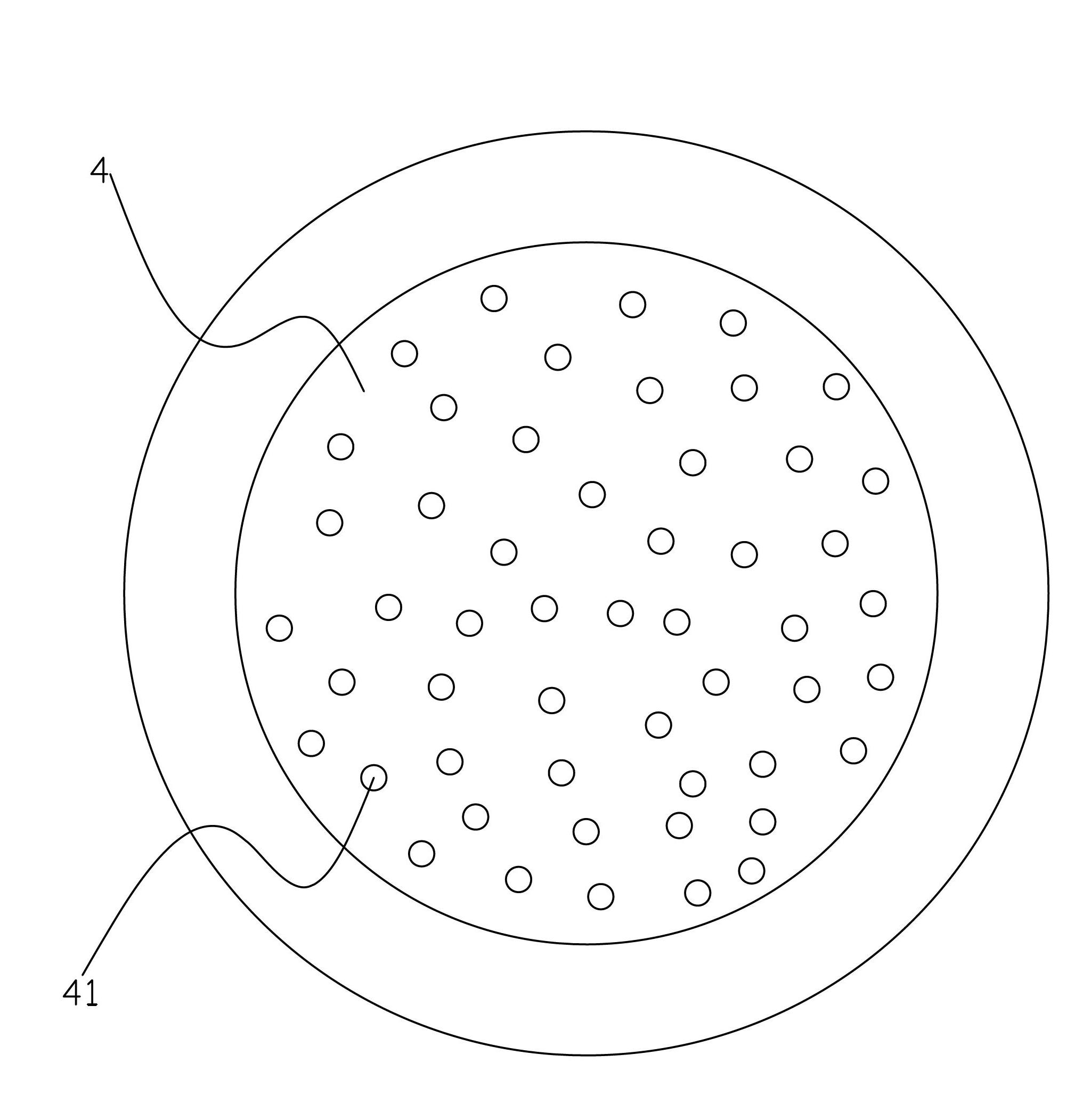

[0016] Further, a furnace bridge 4 is installed on the lower part of the combustion chamber 10, a rotating shaft supporting the furnace bridge 4 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com