Horizontal dual-drum energy-efficient boiler without fireproofing-material furnace-building process

A refractory material, high-efficiency and energy-saving technology, applied in steam boilers, water tube steam boilers, combustion methods, etc., can solve the problems of high equipment cost at the rear of the boiler, large amount of refractory materials, and low thermal efficiency, and achieve convenient transportation and installation. time, increase the layout of the heating surface, and increase the effect of steam output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

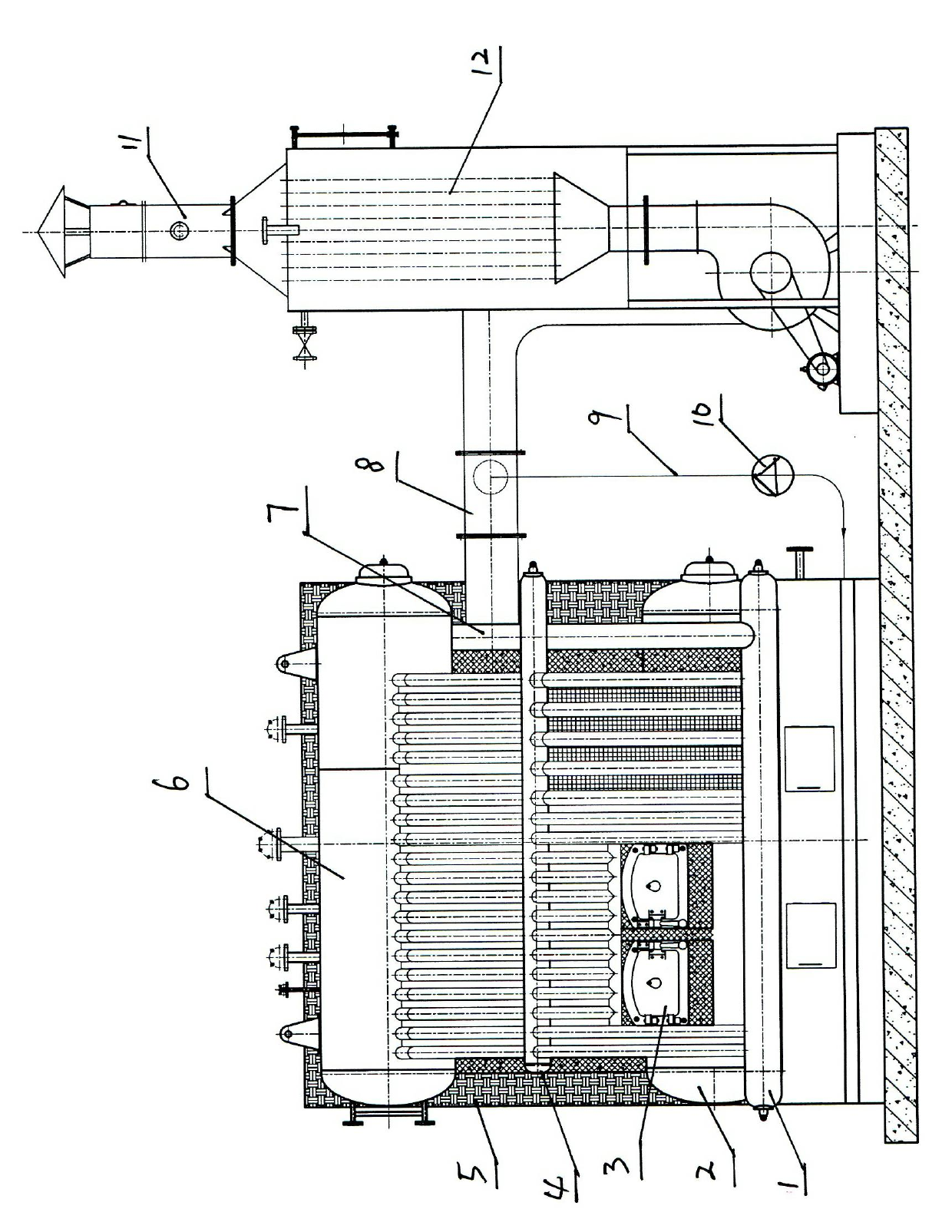

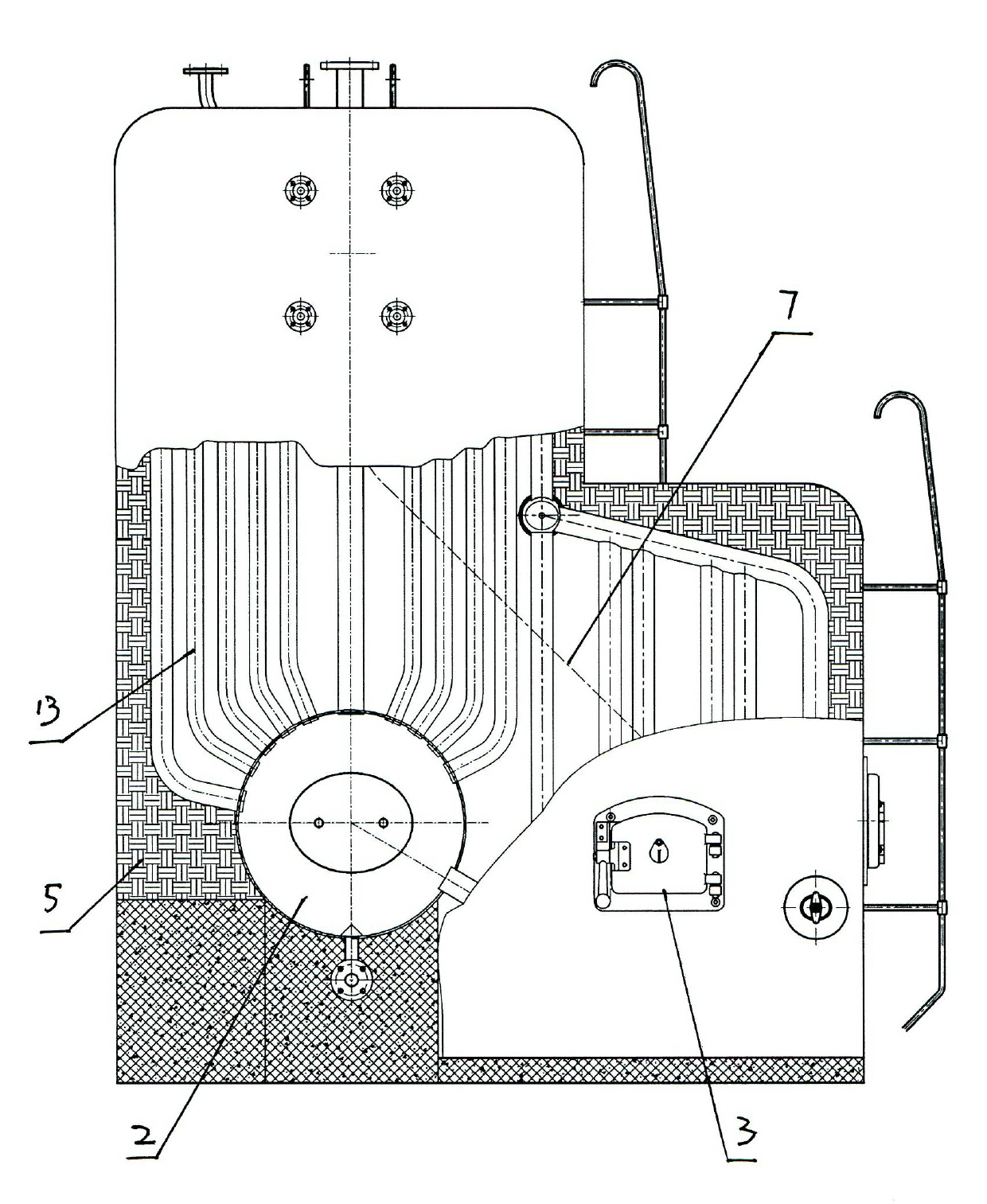

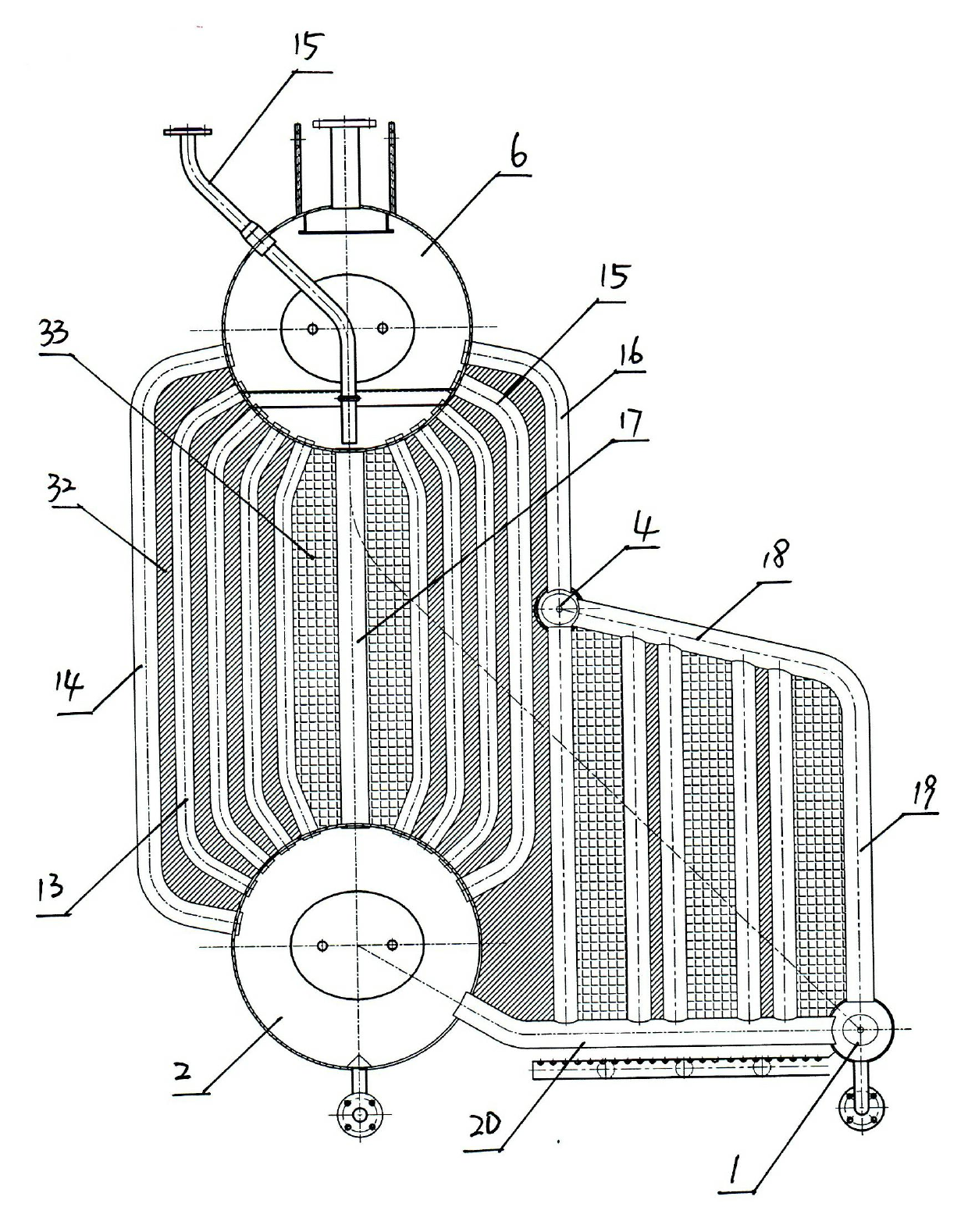

[0029] A horizontal double-drum high-efficiency energy-saving boiler without refractory materials, including an upper drum 6, a lower drum 2 and a furnace, the outside is covered with a thermal insulation layer 5, and several rows of boilers are passed between the upper and lower drums. The convection tube bundles 13 are connected, the outer row of convection tube bundles and the connecting components between the tubes form the outer partition wall 14, the middle row of convective tube bundles and the connecting components between the tubes form the middle partition wall 17, and the inner row of convective tube bundles And the connecting members between the tubes form the inner partition wall 15, the furnace is arranged outside the inner partition wall, the front end tubes of each row of convection tube bundles and the connecting members between the tubes and the tubes form the front end wall 22, each row of convection tube bundles The rear end pipes and the connecting members ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com