Concrete piling process and drilling machine special for same

A concrete and process technology, applied in sheet pile walls, foundation structure engineering, construction, etc., can solve problems such as inability to drill holes, difficulty in ensuring structural strength, and blockage of horizontal drilling holes, so as to prevent pile holes from collapsing and improve drilling efficiency , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

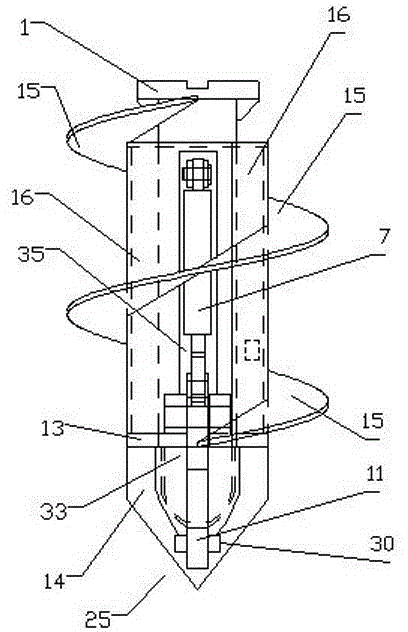

[0088] Embodiment, a kind of concrete pile forming technology, this technology comprises the following steps:

[0089] A. Determine the pile position;

[0090] B. Move the long auger to the working position;

[0091] C. Vertical drilling: the bottom of the long helical drill rod is provided with a first drill bit for drilling in the vertical direction, and the long helical drill rod is provided with a position close to the first drill bit that can gradually open and close in the horizontal direction. The second drill bit on the first drill bit; when drilling, the second drill bit is closed on the first drill bit to form a combined drill bit for drilling down, and the pile hole is drilled to the required depth, and the down drilling is stopped;

[0092] D. Bottom reaming: In this step, the pile hole at the bottom is laterally reamed by gradually opening the second drill bit, until the second drill bit is fully opened, and the bottom reaming is completed to form a pile hole wit...

Embodiment 2

[0102] Embodiment 2, a kind of concrete pile forming technology, this technology comprises the following steps:

[0103] A. Determine the pile position through the GPS positioning module;

[0104] B. Move the long auger drill to the working position through the GPS positioning module;

[0105] C. Vertical drilling: the bottom of the long helical drill rod is provided with a first drill bit for drilling in the vertical direction, and the long helical drill rod is provided with a position close to the first drill bit that can gradually open and close in the horizontal direction. The second drill bit on the first drill bit; when drilling, the second drill bit is closed on the first drill bit to form a combined drill bit for downward drilling, and is positioned by the GPS positioning module, and the pile hole is drilled to the required depth, and the downward drilling is stopped ;

[0106] D. Bottom reaming: In this step, the pile hole at the bottom is horizontally reamed by gra...

Embodiment 3

[0117] Embodiment 3, a kind of concrete pile forming technology, this technology comprises the following operations:

[0118] A. Determine the pile position;

[0119] B. Move the long auger to the working position;

[0120] C. Vertical drilling: the bottom of the long helical drill rod is provided with a first drill bit for drilling in the vertical direction, and the long helical drill rod is provided with a position close to the first drill bit that can gradually open and close in the horizontal direction. The second drill bit on the first drill bit; when drilling, the second drill bit is closed on the first drill bit to form a combined drill bit for drilling down, and the drill pipe hole of the long spiral drill rod is closed; the pile hole is drilled to the required depth, stop drill down;

[0121] D. Bottom reaming: In this step, the pile hole at the bottom is laterally reamed by gradually opening the second drill bit, until the second drill bit is fully opened, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com