Life paper and manufacture method thereof

A technology for household paper and manufacturing methods, applied in chemical instruments and methods, paper, papermaking, etc., can solve problems such as low whiteness, yellowing, and poor stability, and achieve wood resource saving, production cost reduction, and high water absorption performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

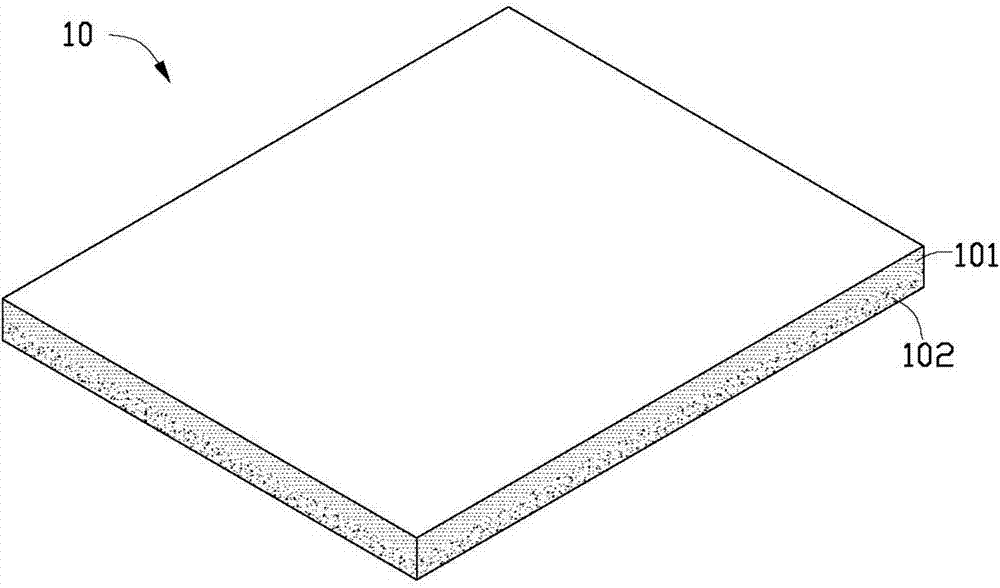

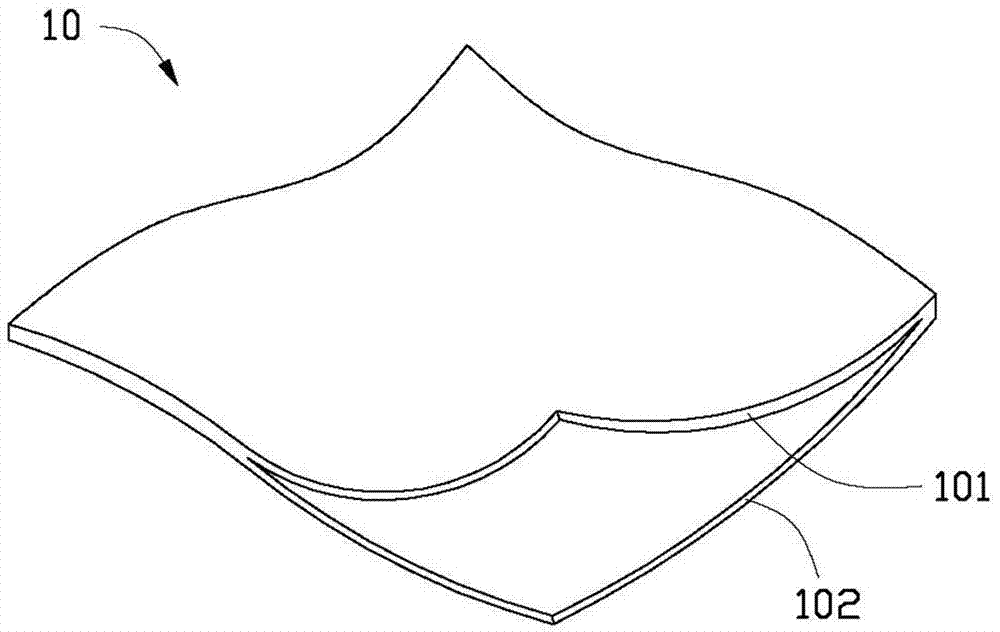

[0038] The household paper provided by the present invention includes at least one single-layer paper, the at least one single-layer paper includes two or more fiber layers, at least one of these fiber layers is formed of bleached chemical pulp, and the other at least one layer It is formed from high-yield pulp or a mixed pulp of high-yield pulp and bleached chemical pulp.

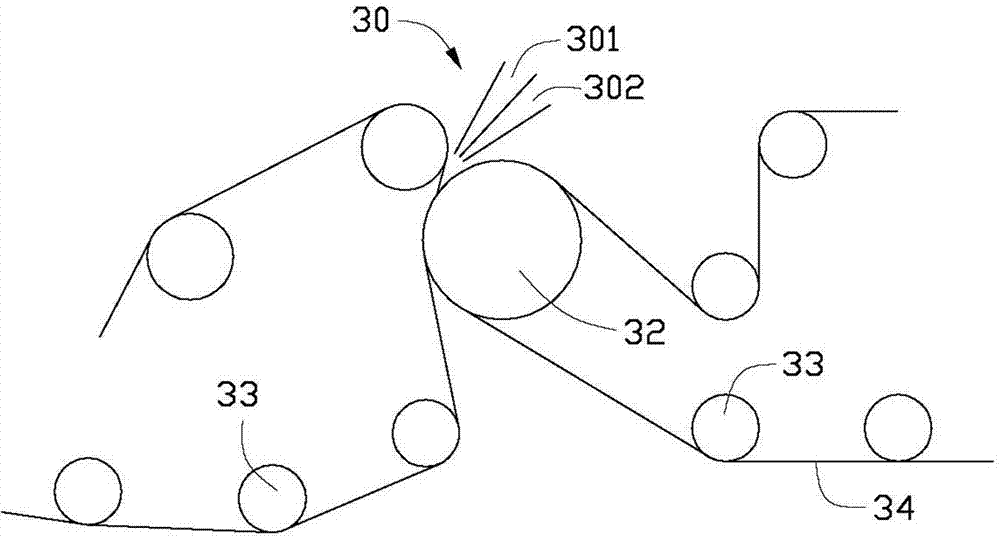

[0039] These single-layer papers with two or more fiber layers can be obtained on a paper machine with a double-layer headbox or multiple (e.g., three or more) headboxes. In the process of forming paper from pulp, the main parts of the surface of these fiber layers are intertwined with each other to form a single-layer paper with an integral structure.

[0040] Bleached chemical pulp is a low-yield pulp, with a yield of about 40% to 60%. The raw materials used in bleaching chemical pulp can be wood fiber raw materials or non-wood fiber raw materials. The wood fiber raw materials include softwood raw materials ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com