Method for devulcanization by burning power plant fire coal mixed with dried sludge

A drying sludge and coal-fired technology, applied in the direction of fuel, solid fuel, petroleum industry, etc., can solve the problems of unfavorable popularization and application, high equipment cost, complicated process, etc., and achieve great social and economic benefits and equipment cost The effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

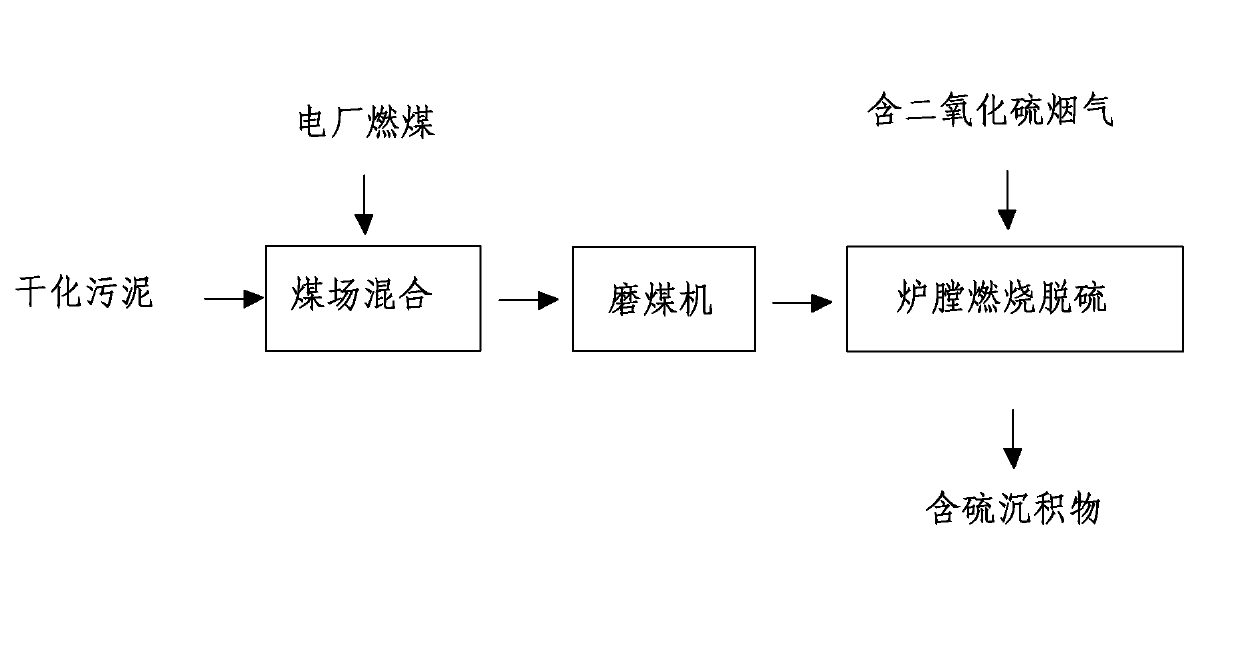

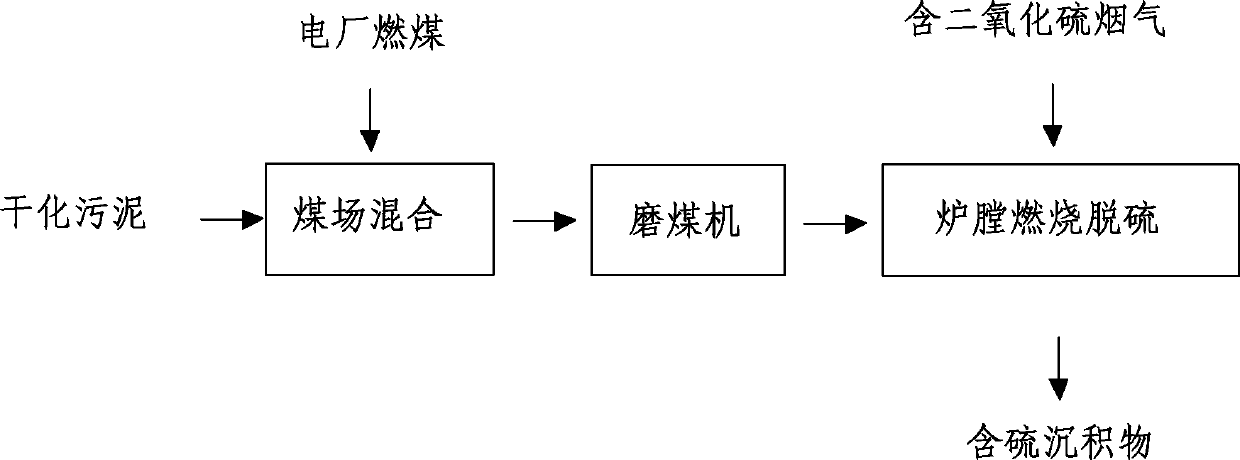

[0033] Such as figure 1 As shown, a method for combustion and desulfurization of coal-fired and dried sludge in a power plant in this embodiment includes the following processing steps: the sludge with a moisture content of 90% produced by waste paper and papermaking sewage is injected into a box-type diaphragm filter press It is made by extrusion dehydration, and the water content of the sludge is reduced to 50% under the pressure of 1.0MPa feed material, and the water content of the sludge is reduced to 40% under the secondary mechanical pressure of 2MPa of the equipment; Dried sludge is sludge produced from waste paper and papermaking sewage, its water content is 40%, and the mass percentage content of calcium ions and magnesium ions is 5%. The mass ratio of dried sludge and power plant coal is 1: Mix thoroughly at a ratio of 6; use a coal mill to grind the power plant coal mixed with dried sludge to 80 mesh, and it is in powder form; put the mixed powder of the ground drie...

Embodiment 2

[0035] Such as figure 1 As shown, a method for combustion and desulfurization of coal-fired and dried sludge in a power plant in this embodiment includes the following processing steps: the sludge with a moisture content of 90% produced by waste paper and papermaking sewage is injected into a box-type diaphragm filter press It is made by extrusion dehydration, and the water content of the sludge is reduced to 47% under the pressure of 1.25MPa feed material, and the water content of the sludge is reduced to 38% under the secondary mechanical pressure of 2.5MPa of the equipment; The dried sludge is the sludge produced by waste paper and papermaking sewage, its water content is 38%, and the mass percentage content of calcium ions and magnesium ions is not less than 5%. The mass ratio of dried sludge and power plant coal is The ratio of 1:6.5 is fully mixed; the power plant coal mixed with dried sludge is ground to 100 mesh with a coal mill, and it is in powder form; the mixed pow...

Embodiment 3

[0037] Such as figure 1 As shown, a method for combustion and desulfurization of coal-fired and dried sludge in a power plant in this embodiment includes the following processing steps: the sludge with a moisture content of 90% produced by waste paper and papermaking sewage is injected into a box-type diaphragm filter press It is made by extrusion and dehydration. Under the pressure of 1.5MPa feed material, the moisture content of the sludge is reduced to below 45%. Under the secondary mechanical pressure of the equipment 3MPa, the sludge is dehydrated for the second time, and the moisture content of the sludge is reduced to below 35%. The obtained dried sludge is the sludge produced by waste paper and papermaking sewage, its water content is 35%, and the mass percentage content of calcium ions and magnesium ions is not less than 5%; Fully mix at a ratio of 1:7; use a coal mill to grind the power plant coal mixed with dried sludge to 130 mesh, and it is in powder form; mix the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com